Plasma treatment device with diffused dissociation

A plasma and processing device technology, applied in the field of plasma processing devices, can solve the problems of narrow inlet passage 200, precipitation, energy consumption, etc., and achieve the effects of accelerating processing speed, increasing density, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

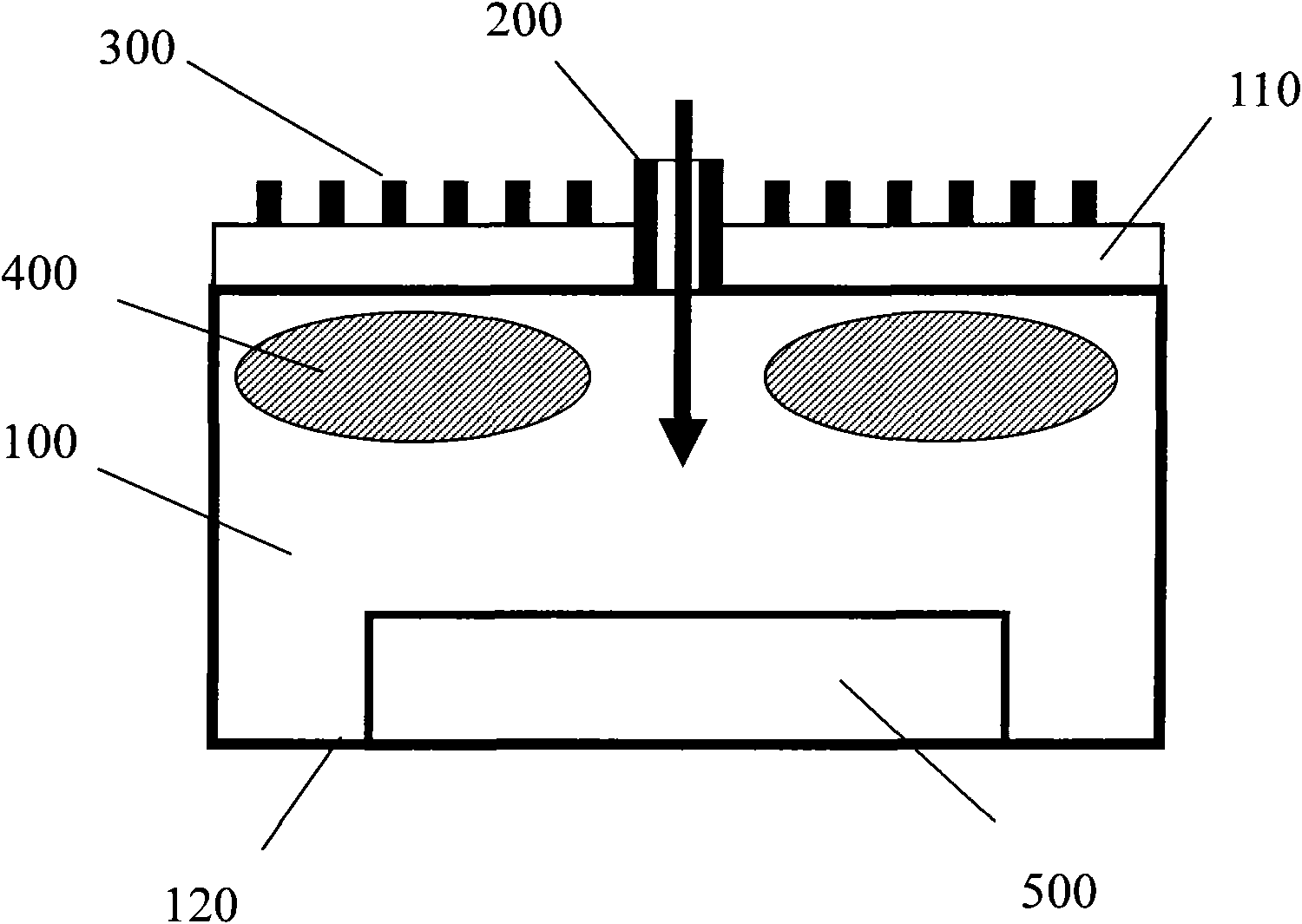

[0037] A plasma processing device with a diffusion dissociation region provided in this embodiment is used to generate an inductively coupled plasma (ICP) introduced into the gas to react with the surface of the substrate to achieve etching of the substrate.

[0038] See image 3 As shown, the plasma processing apparatus includes a processing chamber 10 and an air inlet channel 201 connected through the ceiling 111 of the processing chamber 10 .

[0039] The inside of the processing chamber 10 is vacuum. A substrate 50 to be etched is placed on the bottom plate 12 of the processing chamber 10 .

[0040] The air inlet channel 201 is cylindrical, corresponding to the placement position of the substrate 50 , and vertically arranged on the top plate 111 of the processing chamber 10 . A reactive gas for etching the substrate 50 is introduced into the processing chamber 10 via the gas inlet channel 201, and the reactive gas contains oxygen O 2 or nitrogen N 2 etching gas.

[00...

Embodiment 2

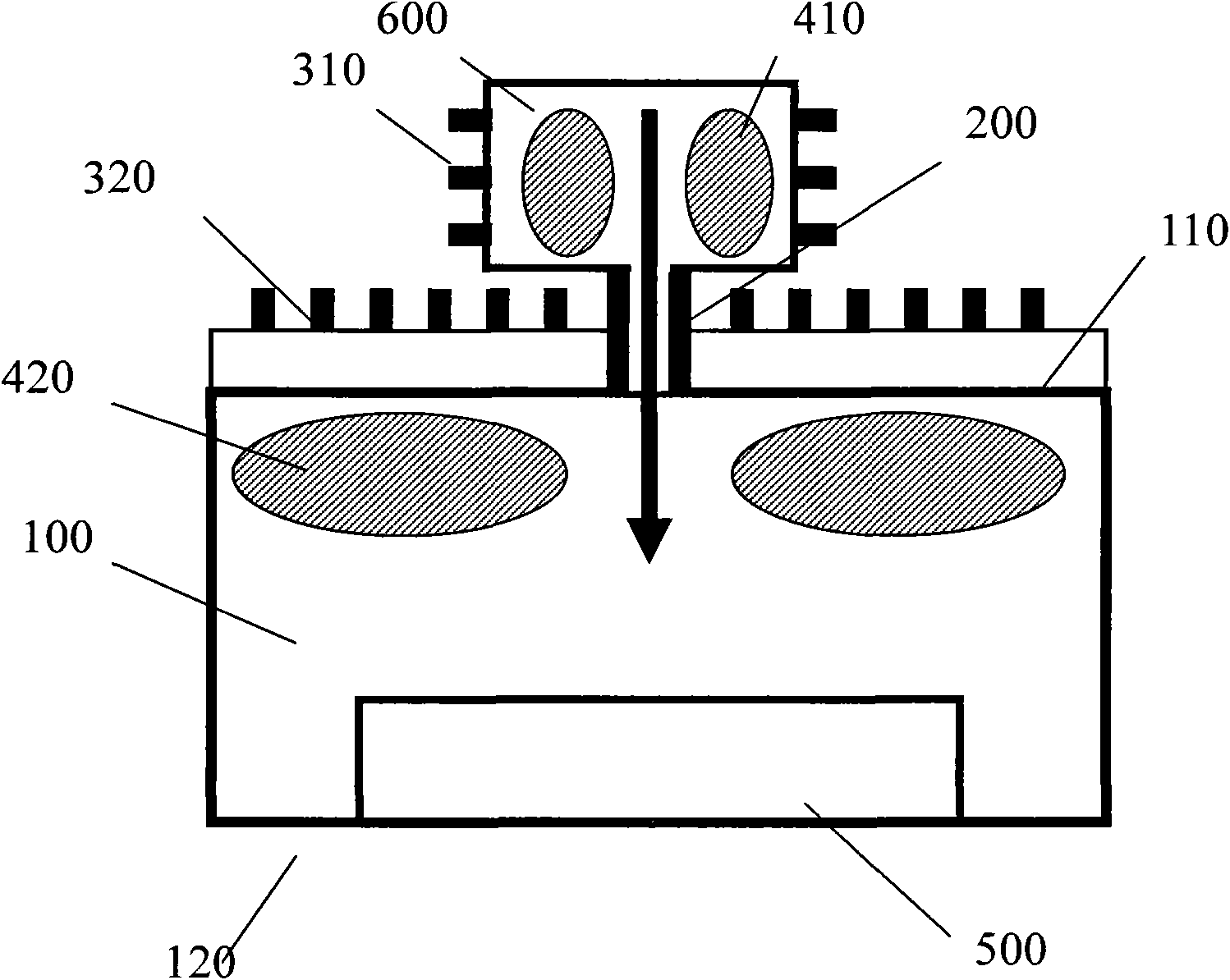

[0050] See Figure 4 As shown, the overall structure of this embodiment is similar to that of the plasma processing apparatus with a diffusion dissociation region provided in Embodiment 1, and the top plate 112 of the vacuum processing chamber 10 is provided with a gas inlet corresponding to the position of the substrate. The channel 202, the first coil 31 and the second coil 32 are respectively arranged on the outside of the inlet channel 202 and the top plate 112 of the processing chamber 10, and the alternating current is respectively passed through to generate the first and second diffusion dissociation of the inductively coupled plasma region, and an induced magnetic field is generated to accelerate the electrons in the plasma, and the gas molecules in the plasma are bombarded twice to fully dissociate to obtain a plasma with a high density of free radicals.

[0051] The only difference is that the shape of the air inlet channel 202 in this embodiment is an inverted funne...

Embodiment 3

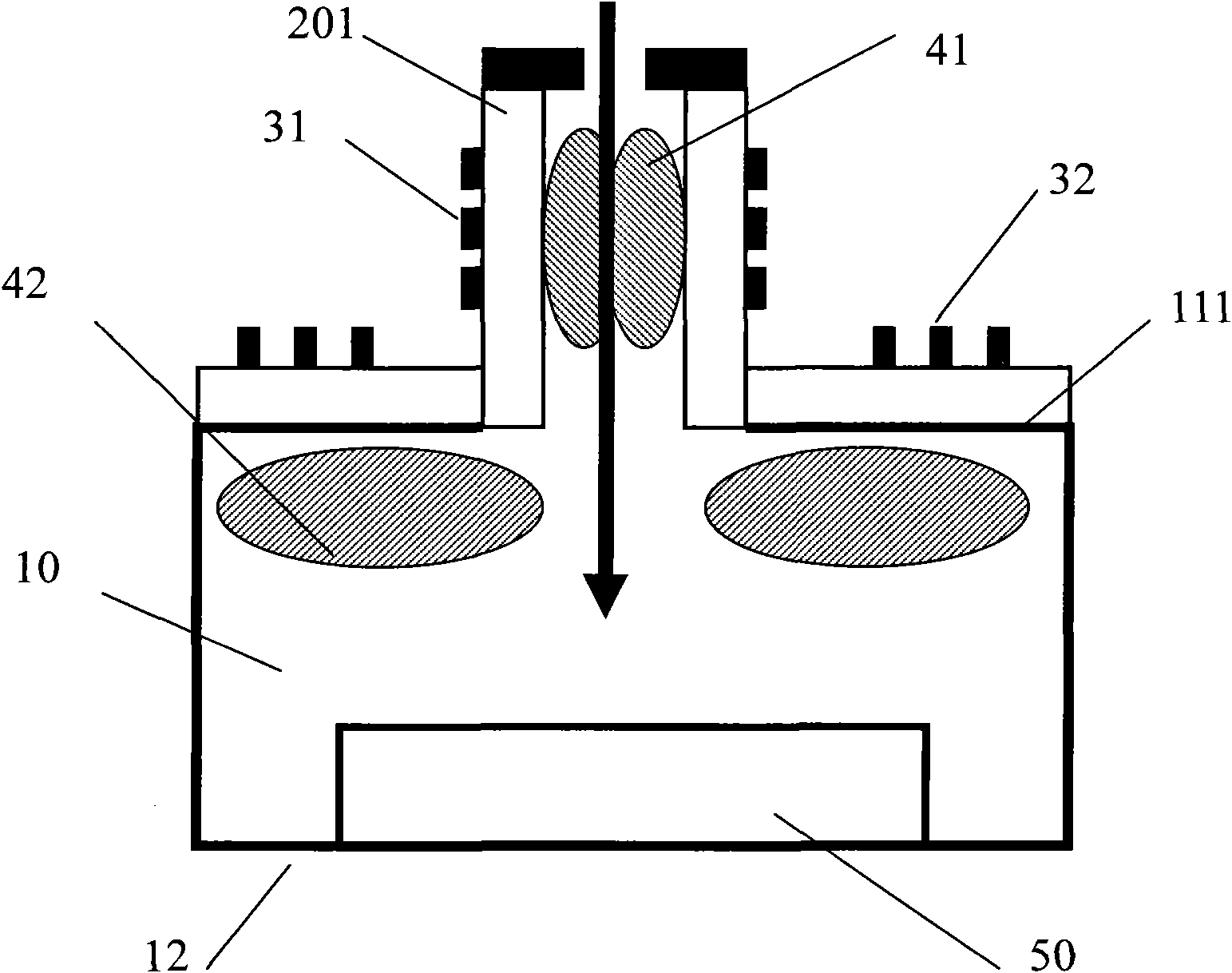

[0054] See Figure 5 As shown, the overall structure of this embodiment is similar to that of the plasma processing device with a diffusion dissociation region provided in Embodiments 1 and 2, and the top plate 113 of the vacuum processing chamber 10 is provided through the top plate 113 corresponding to the position of the substrate. The air inlet channel 203, the first coil 31 and the second coil 32 are respectively arranged outside the air inlet channel 203 and the top plate 113 of the processing chamber 10, and the alternating current is fed into the first and second diffusers of the inductively coupled plasma respectively. Dissociate the region, and generate an induced magnetic field to accelerate the electrons in the plasma, and bombard the gas molecules in the plasma twice, so as to fully dissociate to obtain a plasma with high free radical density.

[0055] The only difference is that in this embodiment, the air inlet channel 203 is trumpet-shaped with a narrow top and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com