Parallel/series-parallel mechanism and robot performance parameter test system

A technology of parameter testing and hybrid mechanism, which is applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as being easily affected by environmental factors and unstable test equipment parameters, so as to facilitate the calculation of kinematics positive solutions and ensure test accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

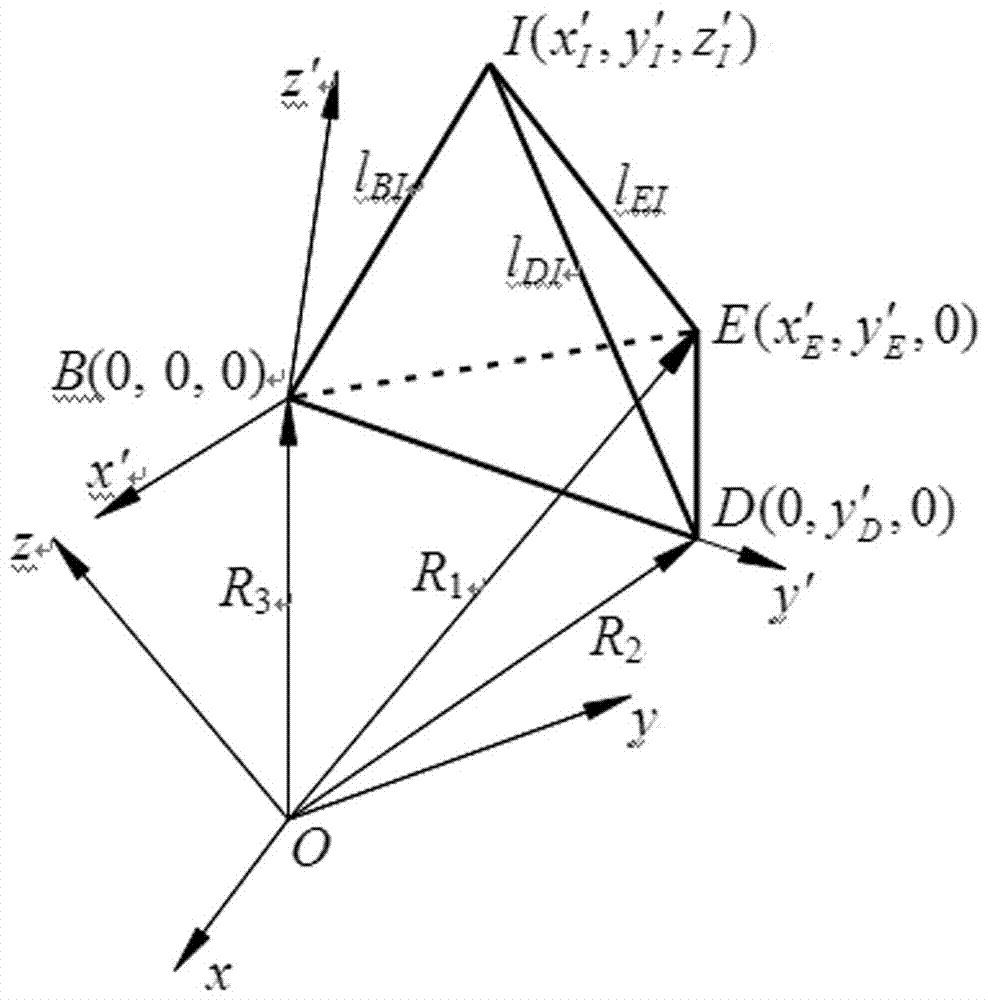

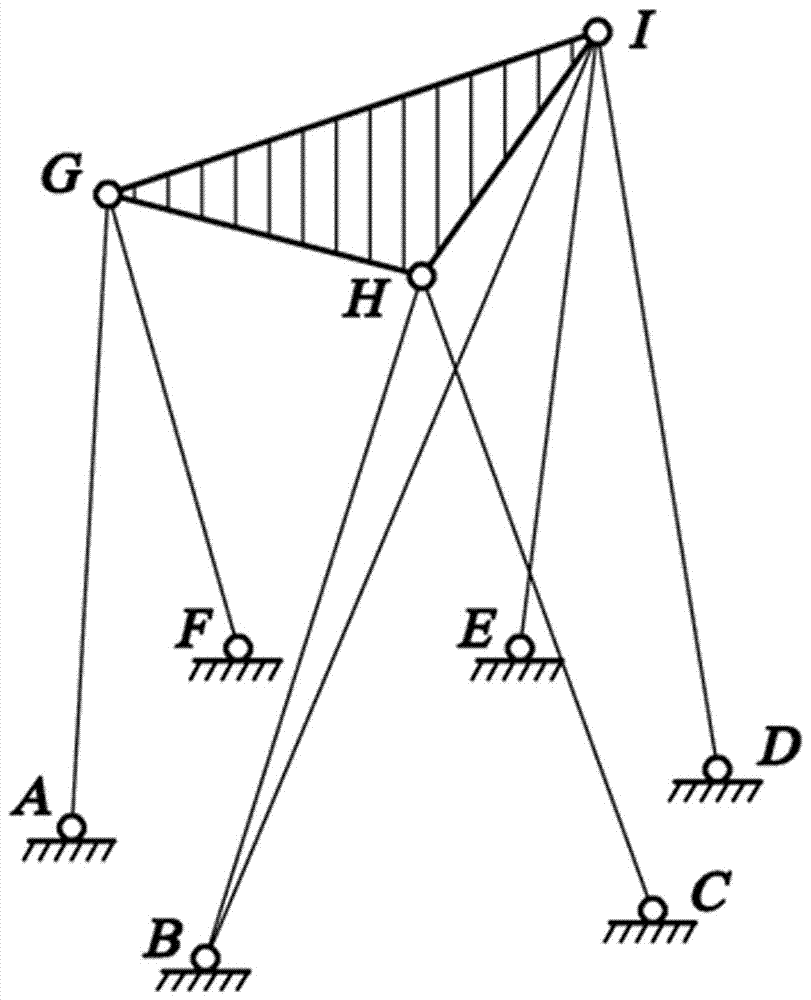

[0035] specific implementation plan

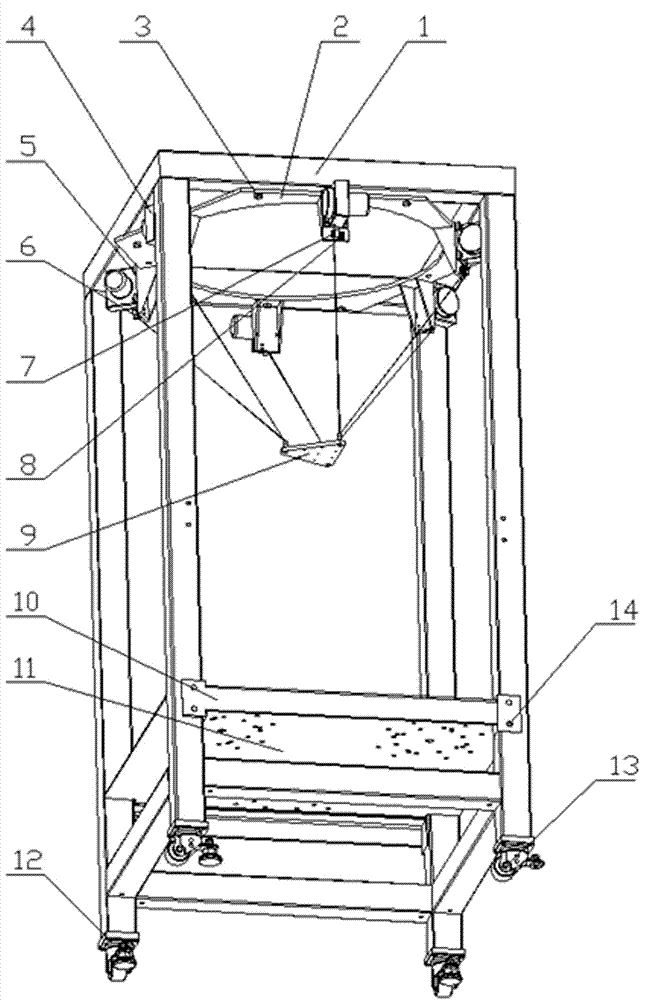

[0036] A parallel / parallel mechanism and robot performance parameter testing system, the system includes a support platform, a test device, a host computer and a servo control system, and the test device is detachably installed on the support platform;

[0037] The support platform is a column-type steel frame structure, a regular hexagonal hexagonal platform 2 is installed on the inner side of the top of the steel frame support platform, and a test device is installed at the bottom of the hexagonal platform 2, and the tested mechanism is connected with the test device and the servo control system at the same time. The control system drives and controls the movement of the tested mechanism. The test device converts the linear motion of the tested mechanism into a rotary motion and outputs the analog quantity through the drive coding function of the test device. The analog output channel of the test device is connected to the host computer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com