Method for preparing isotropic superelastic graphene aerogel

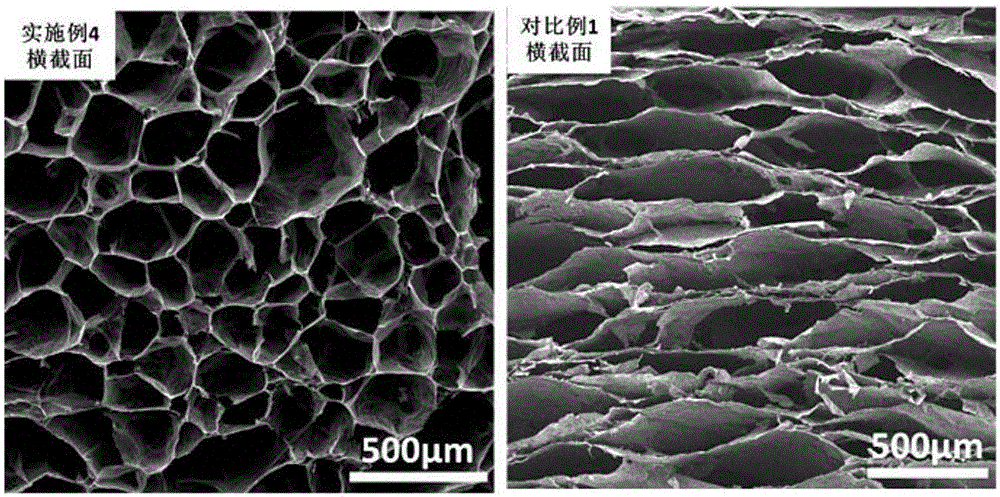

A graphene airgel, isotropic technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of complex preparation process, and achieve the effect of simple process and uniform distribution of pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

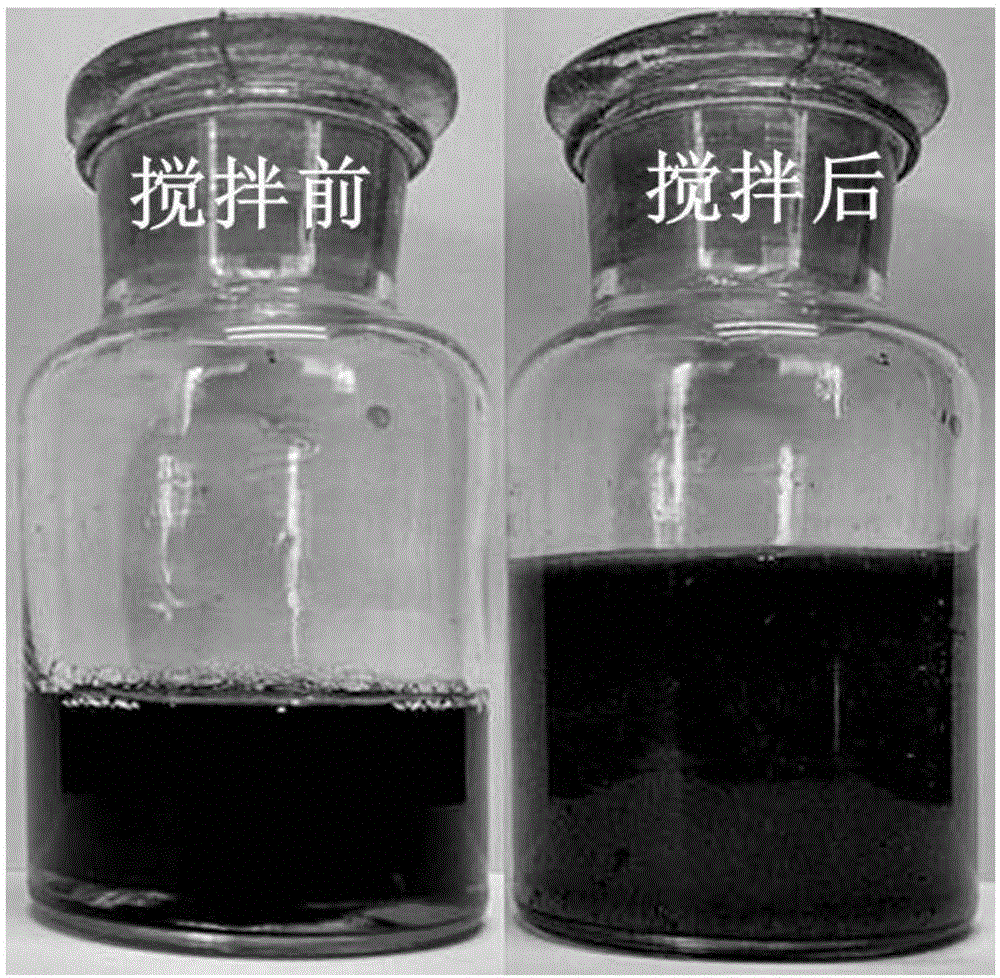

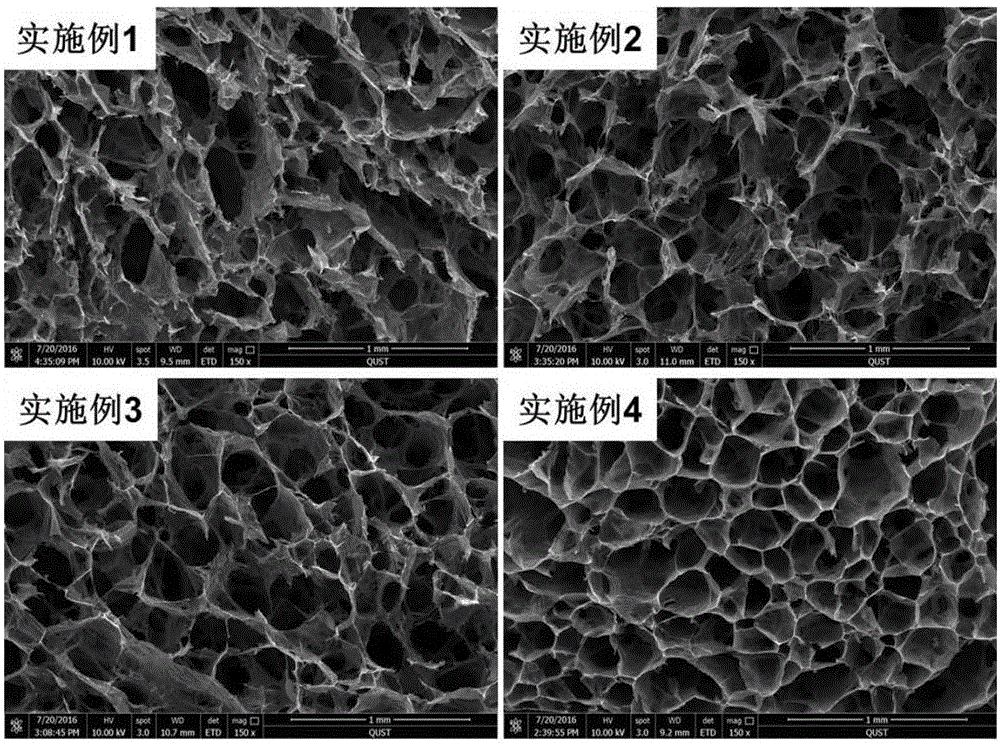

[0047] Prepare 3mg·ml -1 aqueous dispersion of graphene oxide. Take 6ml of the above-mentioned graphene oxide aqueous dispersion and place it in a cylindrical bottle, add 0.5ml of 50mg·ml -1 SDS and 36mg of vitamin C, 300r·min -1 Stir for 3min, then 1000r·min -1 Stir magnetically for 2 minutes, put it in an 80°C blast drying oven for 45 minutes, take it out and cool it to room temperature, put it in a low-temperature environment of -20°C for 3 hours, melt it at room temperature, and then wash it with ethanol for 3 times. The hydrogel was dried in a blast oven at 60°C for 24 hours to obtain a graphene aerogel with good shape retention. Its average pore diameter is 490 μm, and the pore thickness is about 100 nm.

Embodiment 2

[0049] The kind of material used and technological process are the same as embodiment 1, the difference is that the concentration of graphene oxide is 4mg·ml -1 , the dosage of vitamin C is 48mg. Finally, a honeycomb graphene airgel with good shape retention is obtained, and its internal pores are still relatively large with an average pore diameter of 420 μm.

Embodiment 3

[0051] The kind of material used and technological process are the same as embodiment 1, the difference is that the concentration of graphene oxide is 5mg·ml -1 , the dosage of vitamin C is 60mg. A graphene airgel with good shape retention was obtained, and its internal pore size was relatively uniform, with an average pore diameter of 300 μm. Its wall thickness is 120 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com