A kind of preparation method of porous foam carbon material

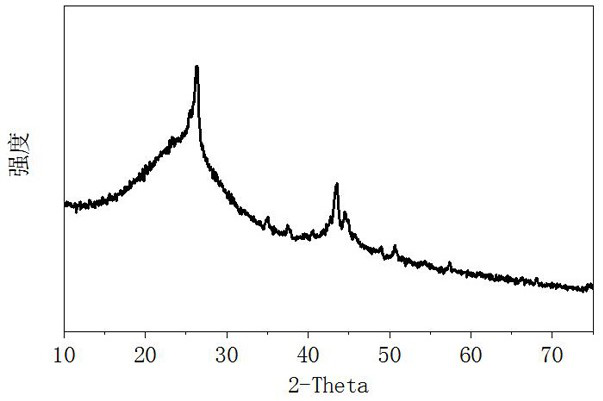

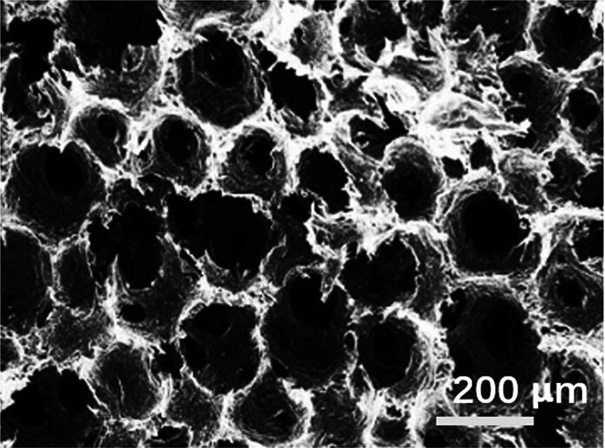

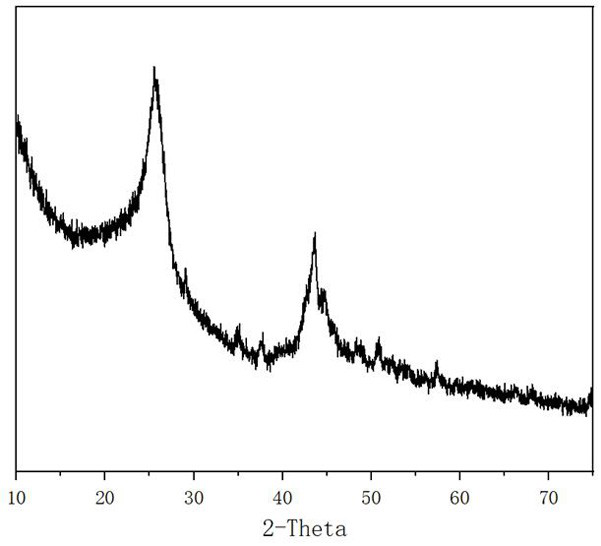

A technology of porous foam and carbon material, applied in the field of preparation of porous foam carbon material, can solve the problems of high graphitization temperature, environmental hazards, limited effect, etc., and achieve the effect of high porosity and high degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: a kind of preparation method of porous carbon foam material, comprises steps as follows:

[0037] (1) Preparation of mesophase pitch foam

[0038] Grind the mesophase pitch to 180 mesh, weigh 10g of the crushed mesophase pitch, add 0.8g of ferric chloride, 0.8g of sodium silicate, and 0.8mL of Tween 80, stir slowly until uniform, then add to the autoclave, Flush into nitrogen to replace the air in the autoclave, keep the pressure in the autoclave at 1.0 MPa, raise the temperature to 400 °C at a rate of 1.5 °C / min, maintain constant temperature and pressure conditions for 10 hours for self-foaming, and naturally cool to room temperature, A mesophase pitch foam is produced.

[0039] (2) Preparation of mesophase pitch foam carbon

[0040] Put the mesophase pitch foam in a tube furnace, program the temperature up to 1000°C at a rate of 1°C / min, and set the flow rate at 0.02m 3 Nitrogen gas was filled at a rate of 1.5 / h for protection, and the temperature wa...

Embodiment 2

[0047] Embodiment 2: a kind of preparation method of porous carbon foam material, comprises steps as follows:

[0048] (1) Preparation of mesophase pitch foam

[0049] Grind the mesophase pitch to 200 mesh, weigh 10g of the crushed mesophase pitch, add 1g of cobalt chloride, 1g of sodium silicate, and 1mL of Tween 80, stir slowly until uniform, then add to the high-pressure reactor, and flush with nitrogen Replace the air in the autoclave, keep the pressure in the autoclave at 1.5 MPa, raise the temperature to 500 °C at a rate of 2 °C / min, maintain constant temperature and pressure for 9 hours for self-foaming, and naturally cool to room temperature to obtain intermediate Phase asphalt foam.

[0050] (2) Preparation of mesophase pitch foam carbon

[0051]Put the mesophase pitch foam in a tube furnace, program the temperature up to 1200°C at a rate of 1.5°C / min, and set the flow rate at 0.04m 3 / h rate was filled with nitrogen for protection, continued heating for 17min and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com