Zr-based metal glass as well as preparation method and application thereof

A technology based on metal and glass, applied in the field of Zr-based metal glass and its preparation, can solve problems such as formation of osseointegration of difficult target tissues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the micro-nanoporous structure on the surface of Zr-based metallic glass comprises the following specific steps: putting the three electrodes into the choline chloride-thiourea eutectic solvent, adjusting the voltage of the working electrode, the temperature of the electrolyte and the voltage output time, applying Voltage to prepare micro-nano porous structure.

[0048] Among them, the three electrodes are: working electrode: flake Zr-based metallic glass, reference electrode: Ag / AgCl, and counter electrode is graphite electrode.

[0049] Zr-based metallic glass is composed of five elements: Zr, Cu, Ni, Ti, and Al, and the mass percentage of each element is Zr 50-65%, Cu 15-25%, Ni 10-15%, Ti 5-10%, Al 5-10%.

[0050] Before putting the Zr-based metallic glass substrate into the choline chloride-thiourea deep eutectic solvent as the working electrode, it is pretreated, first degreasing, then cleaning, then pickling, then cleaning, and then usi...

Embodiment 1

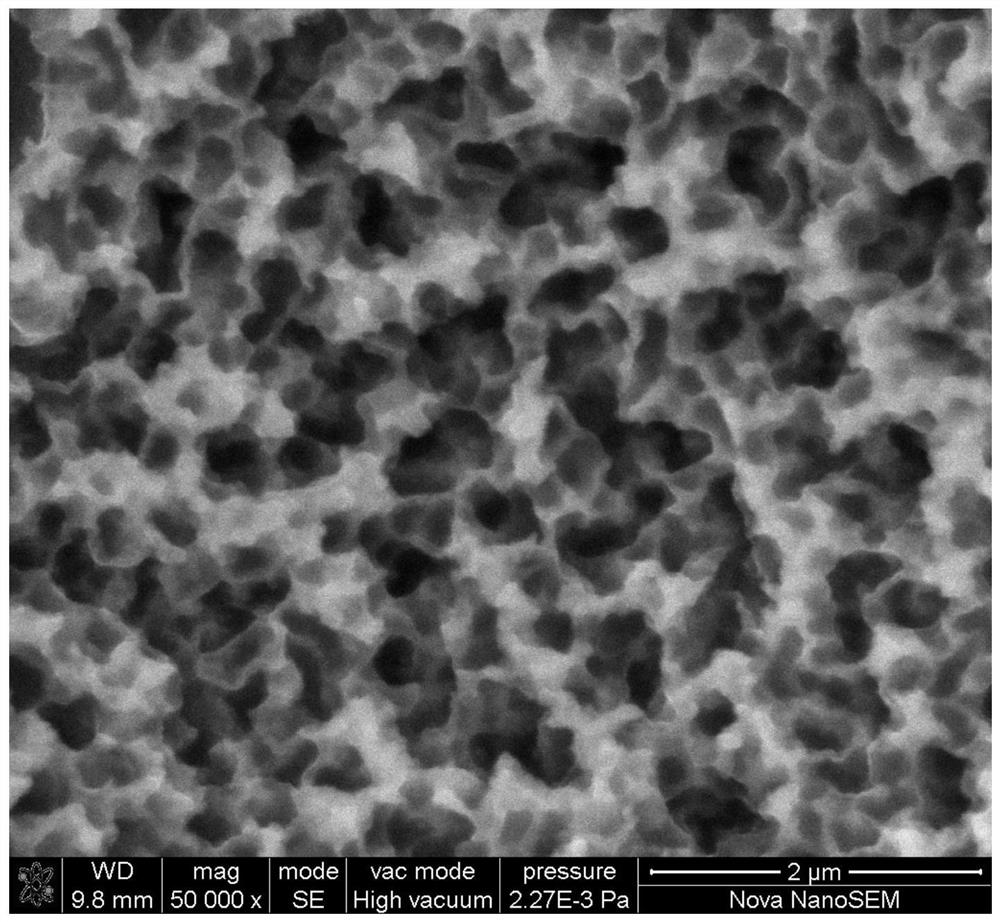

[0052] Put the working electrode, reference electrode and counter electrode into the electrolyte, when the voltage is 2.5V (vs Ag / AgCl), the time is 1.5h, and the temperature is 75°C, a micro-nano porous structure is formed on the surface of the Zr-based metallic glass .

[0053] Such as figure 1 As shown, the micro-nano porous structure obtained on the surface of the Zr-based metallic glass in this example has a pore diameter of 0.3-0.8 μm.

Embodiment 2

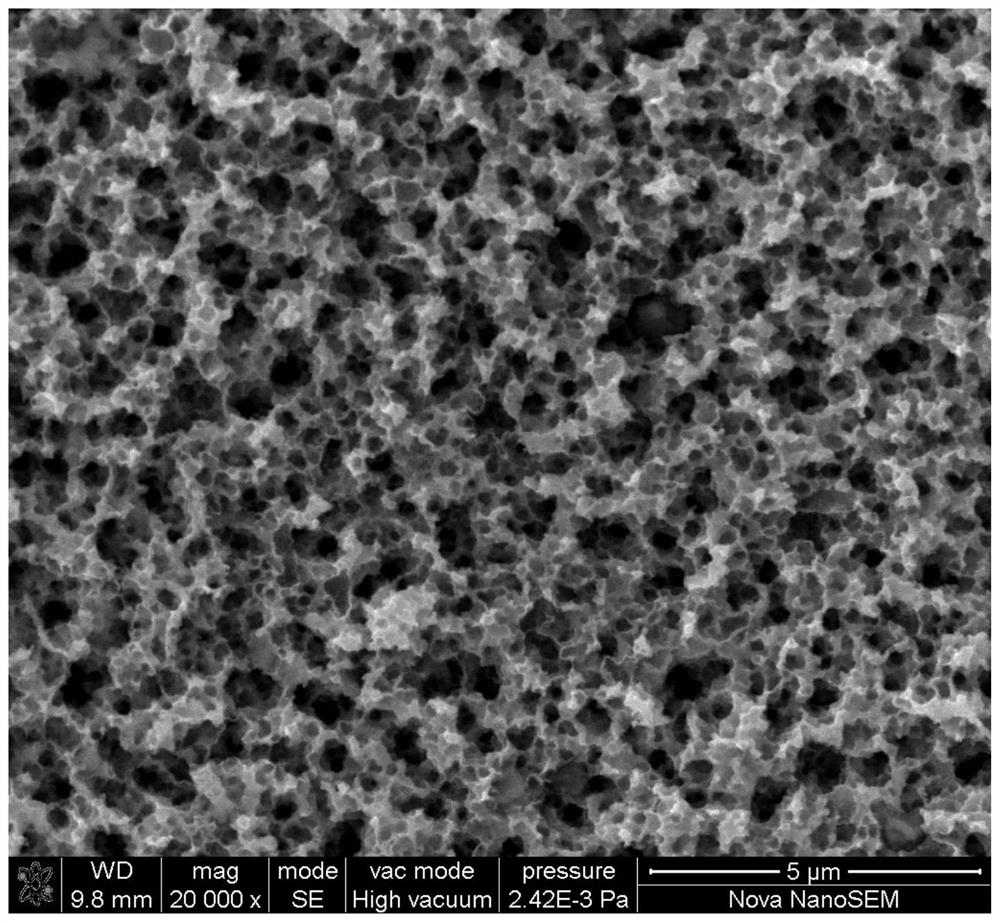

[0055] Put the working electrode, reference electrode and counter electrode into the electrolyte. When the voltage is 3.5V (vs Ag / AgCl), the time is 2h, and the temperature is 85°C, a micro-nanoporous structure is formed on the surface of the Zr-based metallic glass.

[0056] Such as figure 2 As shown, the micro-nano porous structure obtained on the surface of the Zr-based metallic glass in this example has a pore diameter of 0.2-0.7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com