A kind of process and device for preparing benzaldehyde by catalytic oxidation

A technology for catalytic oxidation and benzaldehyde, applied in the preparation of carbon-based compounds, organic compounds, molecular sieve catalysts, etc., can solve the problems of long reaction time of benzyl alcohol, achieve good hydrothermal stability, mild reaction, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of technique that catalytic oxidation prepares benzaldehyde mainly comprises the following steps:

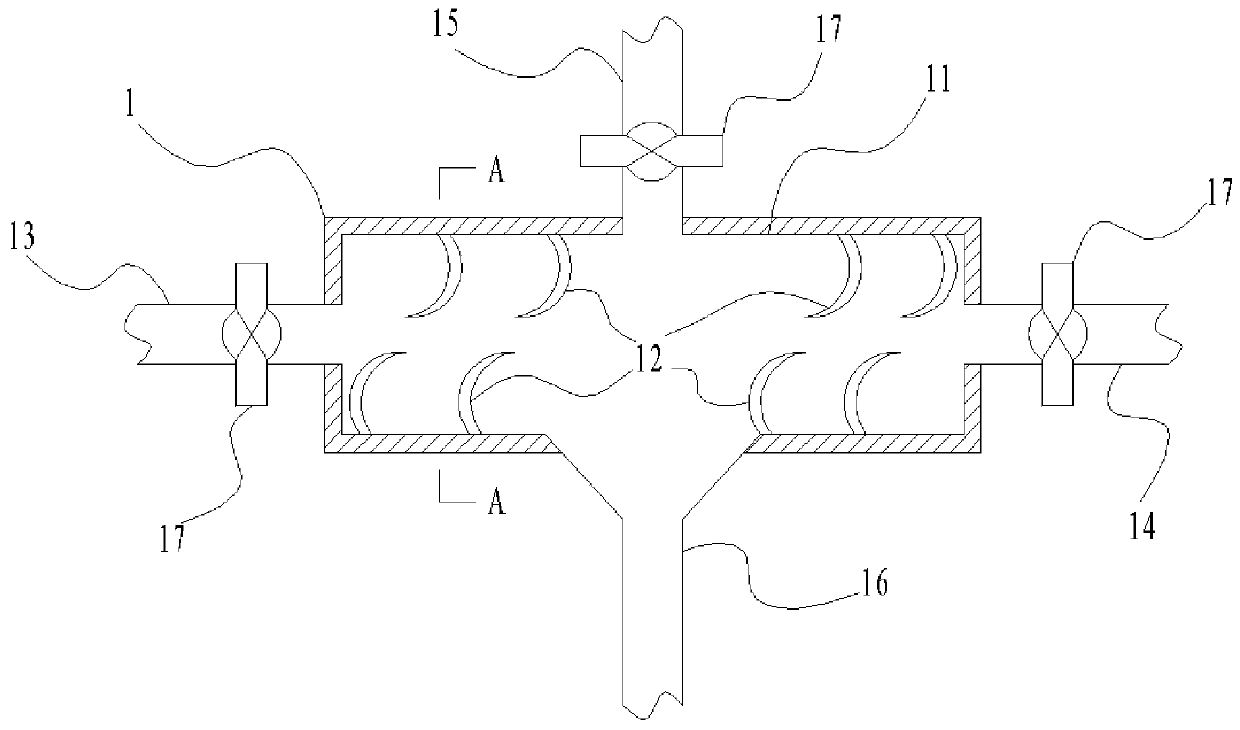

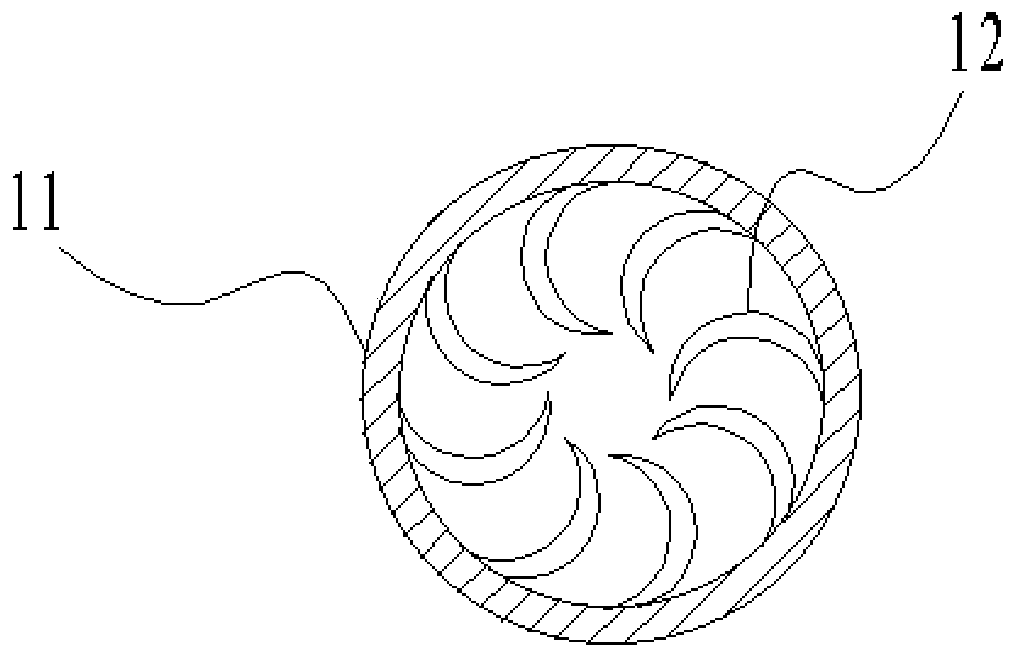

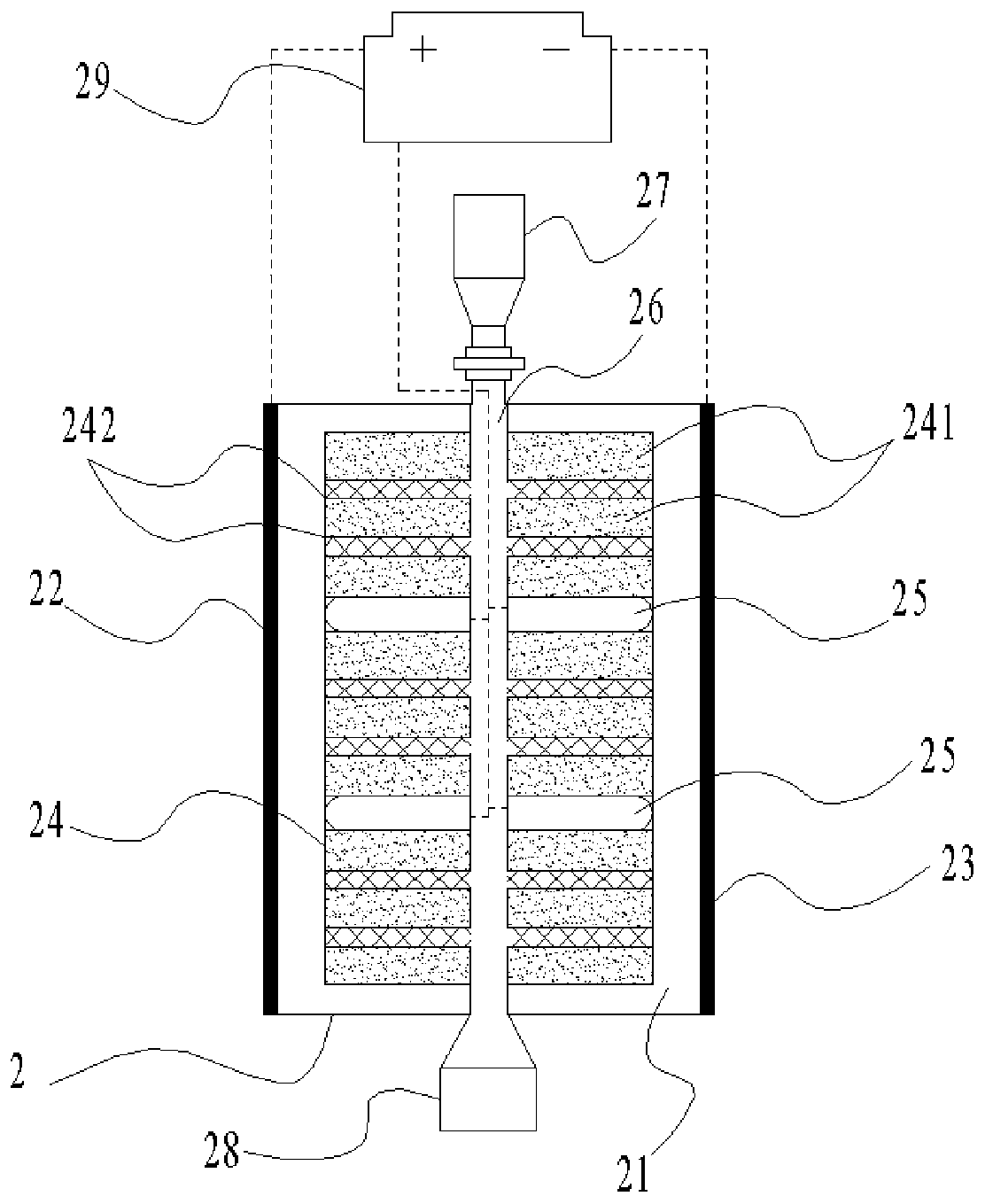

[0033] (1) Gas-phase pre-oxidation: use a steam generator to completely vaporize the benzyl alcohol liquid at 310°C to obtain vaporized benzyl alcohol; enter the vaporized benzyl alcohol into a pressurized tank and pressurize to 2.5Mpa to obtain pressurized vaporized benzyl alcohol; Vaporize benzyl alcohol with volume flow Am 3 / h flows into the vortex mixing device through the pipeline, and at the same time, the volume flow Bm 3 / h into the molecular oxygen, and with the volume flow rate Cm 3 / h into nitrogen as a protective gas, wherein, the volume flow Am of benzyl alcohol 3 The minimum value of / h is 9m 3 / h, the minimum flow rate is limited to ensure that the benzyl alcohol has a certain initial velocity before mixing, which is convenient for more thorough mixing during vortex mixing. The volume flow Am of benzyl alcohol 3 / h, the volume flow rate Bm of m...

Embodiment 2

[0044] A kind of technique that catalytic oxidation prepares benzaldehyde mainly comprises the following steps:

[0045] (1) Gas-phase pre-oxidation: use a steam generator to completely vaporize the benzyl alcohol liquid at 320°C to obtain vaporized benzyl alcohol; enter the vaporized benzyl alcohol into a pressurized tank and pressurize to 3Mpa to obtain pressurized vaporized benzyl alcohol; Pressurized vaporization of benzyl alcohol with volume flow Am 3 / h flows into the vortex mixing device through the pipeline, and at the same time, the volume flow Bm 3 / h into the molecular oxygen, and with the volume flow rate Cm 3 / h into nitrogen as a protective gas, wherein, the volume flow Am of benzyl alcohol 3 The minimum value of / h is 9m 3 / h, the minimum flow rate is limited to ensure that the benzyl alcohol has a certain initial velocity before mixing, which is convenient for more thorough mixing during vortex mixing. The volume flow Am of benzyl alcohol 3 / h, the volume ...

Embodiment 3

[0056] A kind of technique that catalytic oxidation prepares benzaldehyde mainly comprises the following steps:

[0057] (1) Gas-phase pre-oxidation: use a steam generator to completely vaporize the benzyl alcohol liquid at 380°C to obtain vaporized benzyl alcohol; enter the vaporized benzyl alcohol into a pressurized tank and pressurize to 4Mpa to obtain pressurized vaporized benzyl alcohol; Pressurized vaporization of benzyl alcohol with volume flow Am 3 / h flows into the vortex mixing device through the pipeline, and at the same time, the volume flow Bm 3 / h into the molecular oxygen, and with the volume flow rate Cm 3 / h into nitrogen as a protective gas, wherein, the volume flow Am of benzyl alcohol 3 The minimum value of / h is 9m 3 / h, the minimum flow rate is limited to ensure that the benzyl alcohol has a certain initial velocity before mixing, which is convenient for more thorough mixing during vortex mixing. The volume flow Am of benzyl alcohol 3 / h, the volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com