Method for preparing honeycomb mesoporous silica microspheres

A mesoporous silica and honeycomb technology, applied in the field of materials science, can solve the problems of poor morphology of honeycomb mesoporous silica, and achieve the effects of easy functional modification, simple operation process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

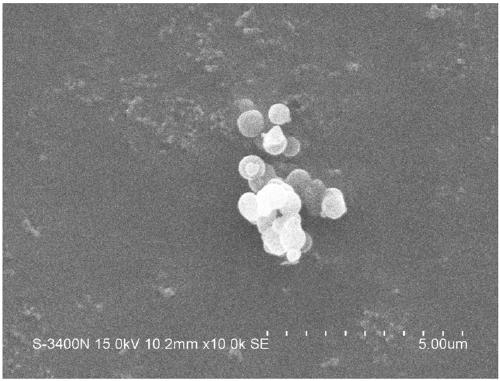

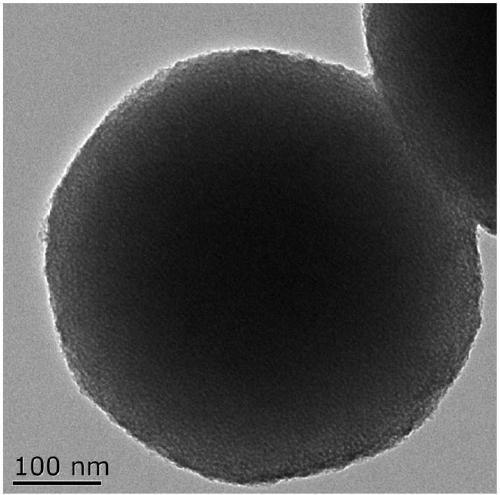

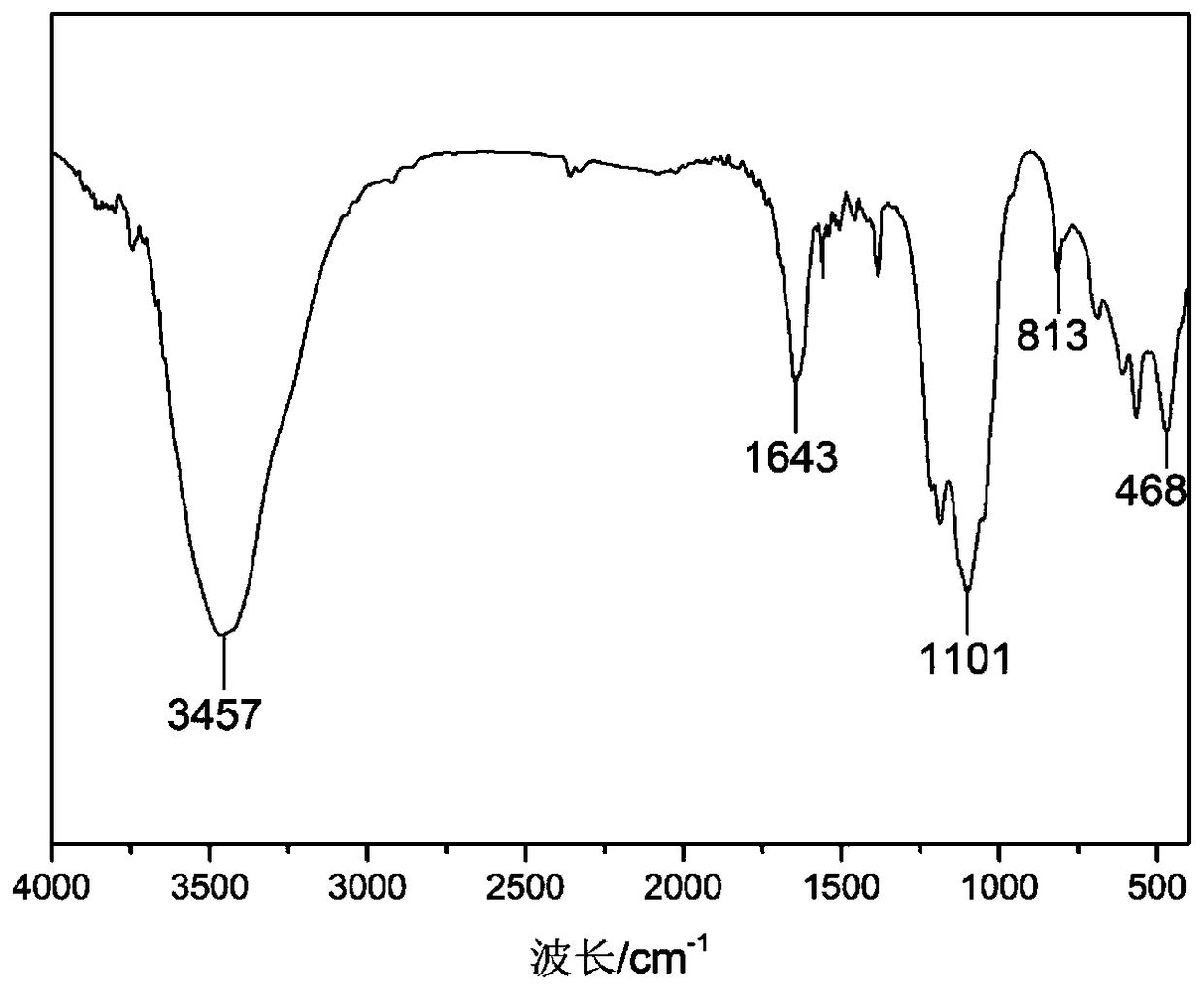

[0032] Example 1 Preparation of Honeycomb Mesoporous Silica

[0033] 1) Dissolve 1.16g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer in 100mL deionized water, stir and disperse evenly to obtain uniform polyethylene oxide-polypropylene oxide -Polyethylene oxide triblock copolymer solution:

[0034] 2) Add 3mL of 1mol / L hydrochloric acid solution and 0.5g potassium chloride to the polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer solution obtained in step (1), and stir evenly Obtain a clear solution:

[0035] 3) Add 3.46 g of tetraethyl orthosilicate to the acidic surfactant solution obtained in step (2) at a stirring speed of 200 r / min, and stir at room temperature for 4 hours to obtain a clear and transparent solution;

[0036] 4) Add the clear and transparent solution obtained in step (3) into pH=8.0 polyethylene glycol phosphate buffer solution by spraying, magnetically stir for 300 min, and centrifuge at 7000 rp...

Embodiment 2

[0041] 1) Dissolve 1.16g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer in 100mL deionized water, stir and disperse evenly to obtain uniform polyethylene oxide-polypropylene oxide -Polyethylene oxide triblock copolymer solution:

[0042]2) Add 4mL of 1mol / L hydrochloric acid solution and 0.5g potassium chloride to the polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer solution obtained in step (1), and stir evenly Obtain a clear solution:

[0043] 3) Under the condition of a stirring speed of 200r / min, directly add 3.46g of tetraethyl orthosilicate into the transparent solution in step (2), and stir at room temperature for 4 hours to obtain a clear and transparent solution;

[0044] 4) Add the clear and transparent solution obtained in step (3) into the pH=7.0 polyethylene glycol phosphate buffer solution by spraying, stir magnetically for 20 minutes, and centrifuge at 7000 rpm to obtain a white precipitate: the polye...

Embodiment 3

[0048] 1) Dissolve 1.16g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer in 100mL deionized water, stir and disperse evenly to obtain uniform polyethylene oxide-polypropylene oxide -Polyethylene oxide triblock copolymer solution:

[0049] 2) Add 3mL of 1mol / L hydrochloric acid solution and 0.5g potassium chloride to the polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer solution obtained in step (1), and stir evenly Obtain a clear solution:

[0050] 3) Under the condition of a stirring speed of 200r / min, directly add 3.46g of tetraethyl orthosilicate into the transparent solution in step (2), and stir at room temperature for 4 hours to obtain a clear and transparent solution:

[0051] 4) Add the clear and transparent solution obtained in step (3) into a pH=8.0 polyethylene glycol phosphate buffer solution by spraying, ultrasonically disperse for 30 minutes, and centrifuge at 8000 rpm to obtain a white precipitate: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com