A kind of bimetallic molecular sieve catalyst and its preparation and application

A molecular sieve and catalyst technology, applied in the field of metal modified catalysts, can solve the problem of less active sites, and achieve the effects of improving the oxidation rate, not easily blocking pores, and maintaining stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

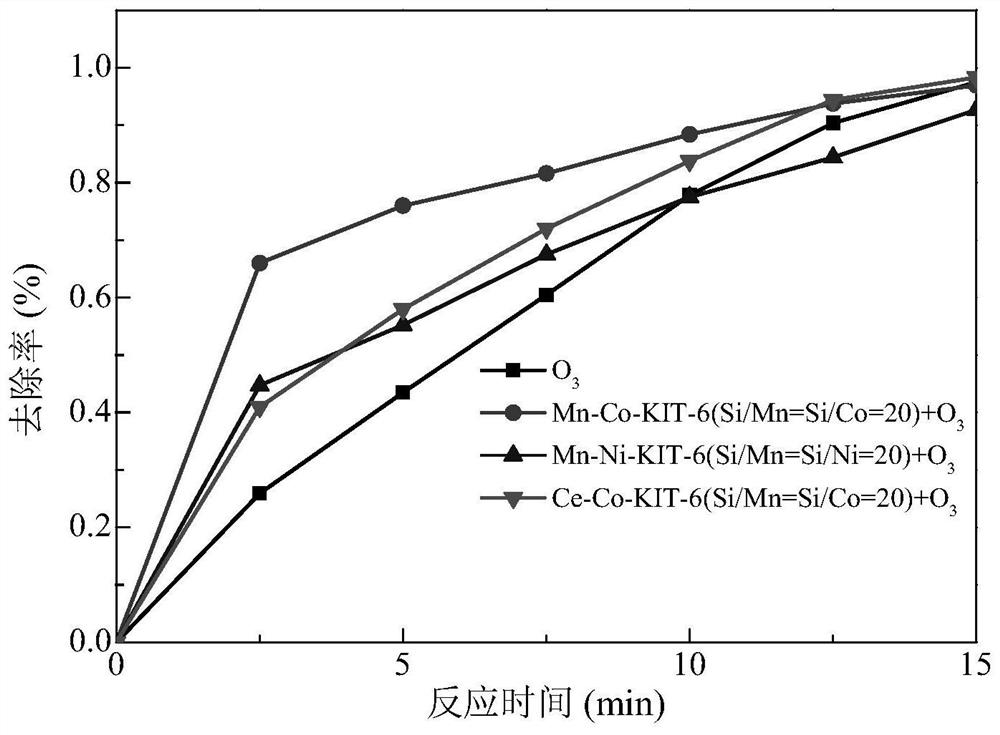

[0042] o 3 Oxidation test: the simulated wastewater is 1L of 20mg / L carbamazepine solution (the natural pH value of the wastewater is 6.5 when the pH is not adjusted), and ozone is continuously added as the oxidant, the gas flow rate is 0.25L / min, O 3 The gas phase concentration is 2mg / L.

[0043] During the contact reaction time of ozone, molecular sieve catalyst and waste water within 0-15 minutes, samples are taken and detected at intervals of 2-5 minutes. When reacting for 2.5 minutes, O 3 The removal rate of carbamazepine was 25.9%, reaching 77.8% in 10 minutes (see figure 2 ).

Embodiment 2

[0045] Catalyst preparation:

[0046] 5gP 123 Dissolve in 175mL of dilute hydrochloric acid solution with a concentration of 0.5mol / L, and stir for 1h;

[0047]Add 5g of n-butanol, stir in a water bath at 35°C for 1h; add 10.75g of ethyl orthosilicate, and then mix 0.634g of nickel acetate and 0.93g of Mn(NO 3 ) 2 4H 2 O was added to the solution to dissolve, and stirred for 24 hours in a water bath at 35°C;

[0048] Afterwards, the solution was put into a hydrothermal reactor and crystallized in an oven at 100°C for 24 hours. After the reaction, the reactor was taken out to cool down to room temperature naturally, suction filtered, and washed.

[0049] The obtained product was dried in an oven at 100°C for 6h, then calcined in a muffle furnace at 550°C for 6h, and the temperature increase rate of the muffle furnace was 2°C / min to obtain the catalyst Mn-Ni-KIT-6 (Si / Mn=Si / Ni=20). Detected by BET method, the specific surface area of the obtained molecular sieve cataly...

Embodiment 3

[0054] Catalyst preparation:

[0055] 5 g P 123 Dissolve in 175mL of dilute hydrochloric acid solution with a concentration of 0.5mol / L, and stir for 1h; add 5g of n-butanol, and stir for 1h in a water bath at 35°C; Co=20 will 0.75gCo(NO 3 ) 2 ·6H 2 O and 1.12gCe(NO 3 ) 2 ·6H 2 O was added to the solution to dissolve, and stirred in a water bath at 35°C for 24 hours; then the solution was placed in a hydrothermal reactor and crystallized in an oven at 100°C for 24 hours. After the reaction, the reactor was taken out and cooled to room temperature naturally, suction filtered, and washed.

[0056] The obtained product was dried in an oven at 100°C for 6h, then calcined in a muffle furnace at 550°C for 6h, and the temperature increase rate of the muffle furnace was 2°C / min to obtain the catalyst Ce-Co-KIT-6 (Si / Ce=Si / Co = 20). Detected by BET method, the specific surface area of the obtained molecular sieve catalyst is 742m 2 / g, the average pore diameter is 6.51nm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com