A kind of foaming agent and preparation method thereof

A technology of foaming agent and fat, which is applied in the field of foaming agent and its preparation, can solve the problems of small foam concrete, limited amount of cement, thin and fragile cell walls, etc., and achieve uniform and delicate foam, low price, and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

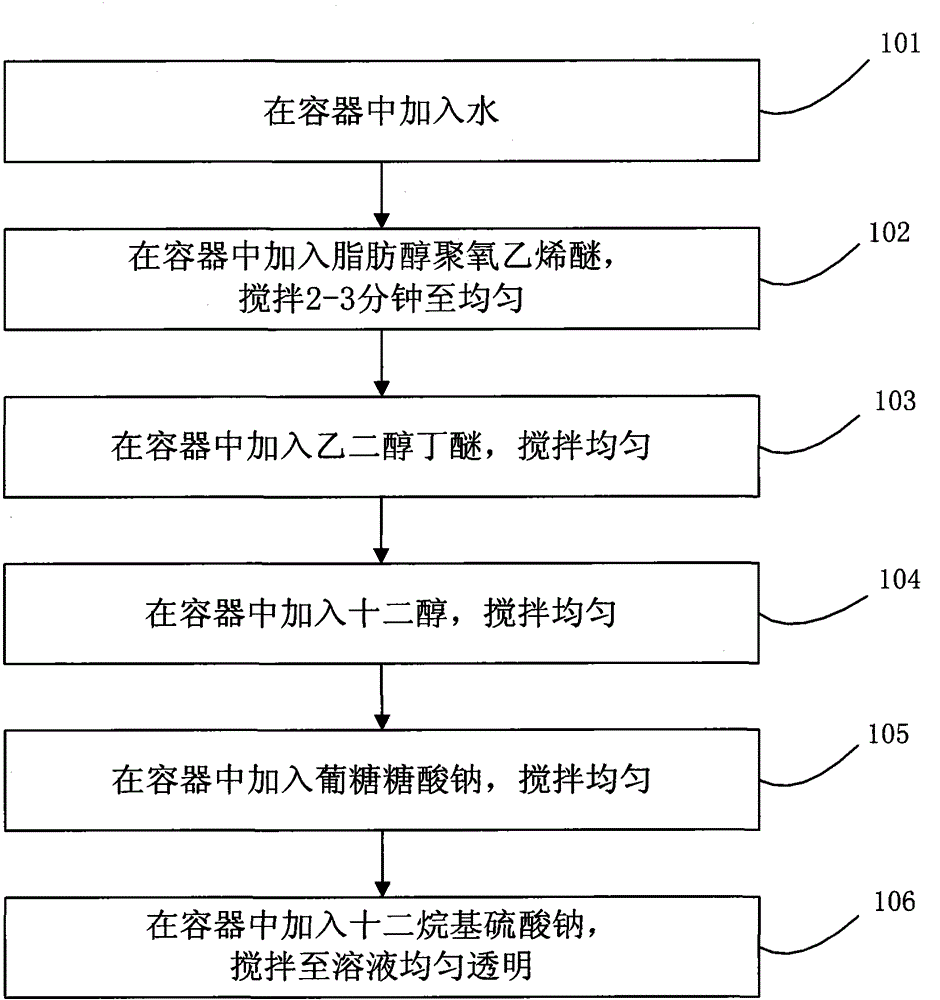

[0019] In a specific embodiment of the present invention, a foaming agent is provided, which is suitable for preparing ultra-low density foam concrete with sulphoaluminate cement, including sodium lauryl sulfate, fatty alcohol polyoxyethylene ether, lauryl alcohol, ethylene glycol Alcohol Butyl Ether, Sodium Gluconate and Water.

[0020] Wherein the percentages of sodium lauryl sulfate, fatty alcohol polyoxyethylene ether, lauryl alcohol, ethylene glycol butyl ether, sodium gluconate and water in the total mass of blowing agent are respectively: sodium lauryl sulfate is 1% to 8%, fatty alcohol polyoxyethylene ether 15% to 35%, lauryl alcohol 0.5% to 3.5%, butyl glycol ether 12% to 38%, sodium gluconate 0.05% to 2% , water is the remaining percentage.

[0021] When this kind of foaming agent is used to make ultra-low-density foamed concrete, it not only has enough stability to keep its shape, but also can make the pores of the formed foamed concrete larger, the wall of the hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com