Rubber hose sheath winding machine

A winding machine and frame technology, applied in the field of hose sheath winding machine, can solve the problems of unstable quality, high labor intensity, low production efficiency, etc., and achieve the effect of stable winding quality, low labor intensity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

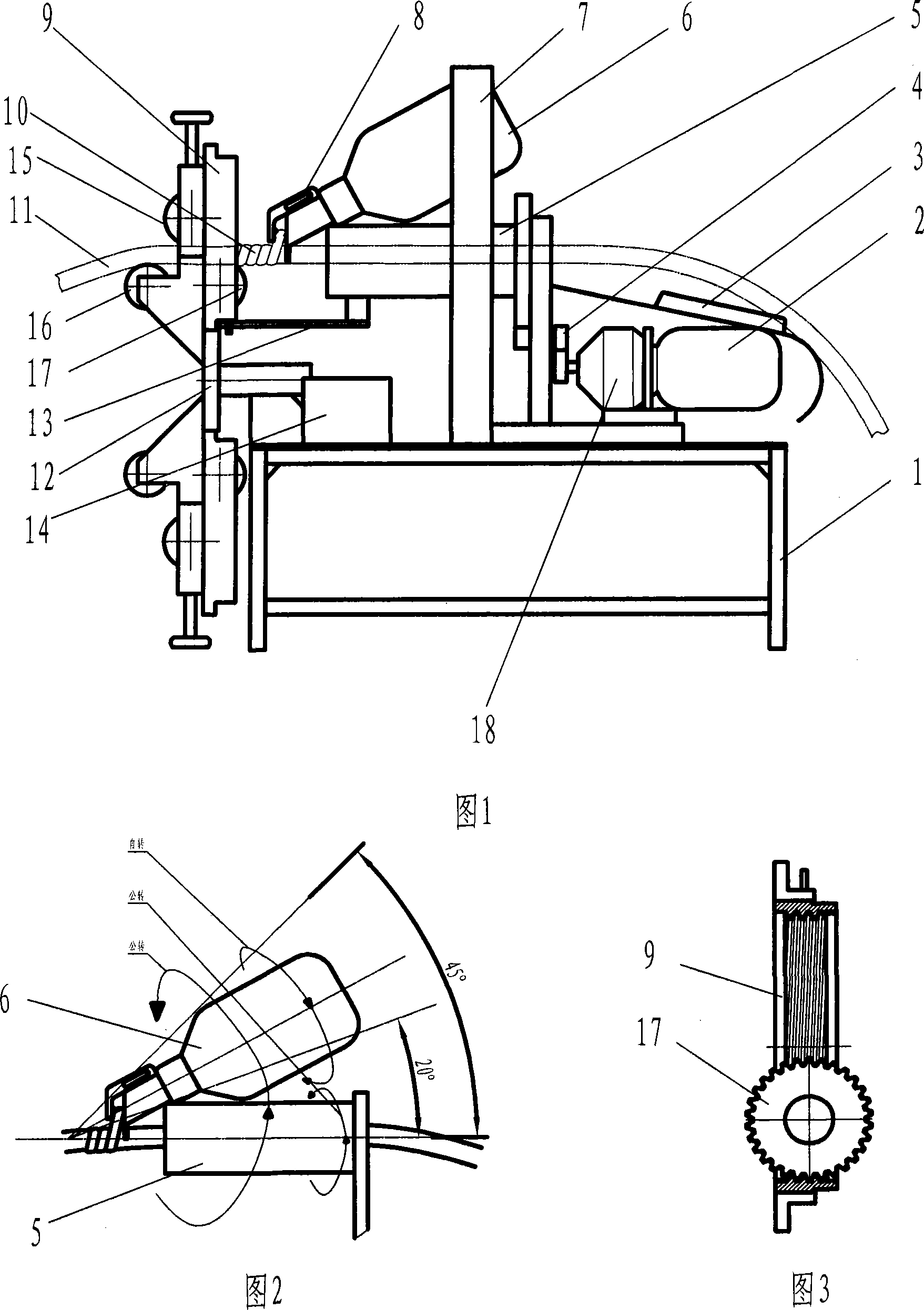

[0015] Referring to Fig. 1, Fig. 2 and Fig. 3, a hollow feed cylinder 5 is provided on the frame 1, and the feed cylinder 5 is driven by the motor assembly 2 through the reducer 18 and the gear 4 to rotate around its axis, and the feed cylinder 5 is installed with The charging barrel 6 whose outlet corresponds to the outlet of the feeding barrel 5, the charging barrel 6 can rotate freely around its axis, and the front end of the charging barrel 6 is provided with a winding pulley assembly 8, and the axial centerline of the charging barrel 6 is in line with the feeding The angle between the axial centerlines of the cylinder 5 is 20°~45°. The feeding assembly corresponding to the feeding cylinder 5 is provided on the frame 1. The feeding assembly is installed on the bracket 12 that can be adjusted and rotated around the frame 1. There are four groups of front support wheels, rear support wheels 16 and pressure rollers 15. The front support wheels are worm wheel support wheels 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com