Automatic film winding device, slitting and winding system, and method of producing rolled film

A winding device, film winding technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve problems such as multi-polarization difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

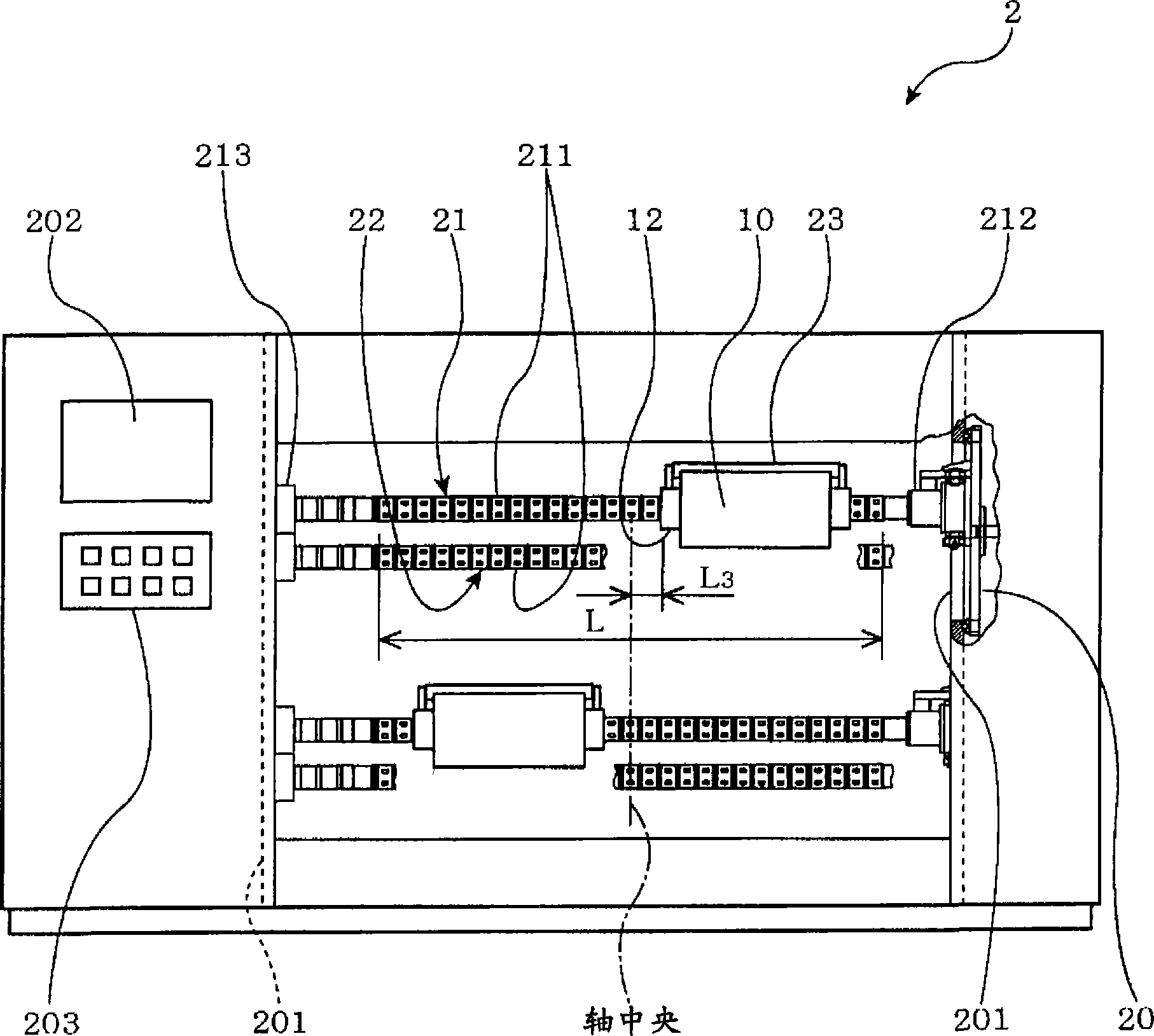

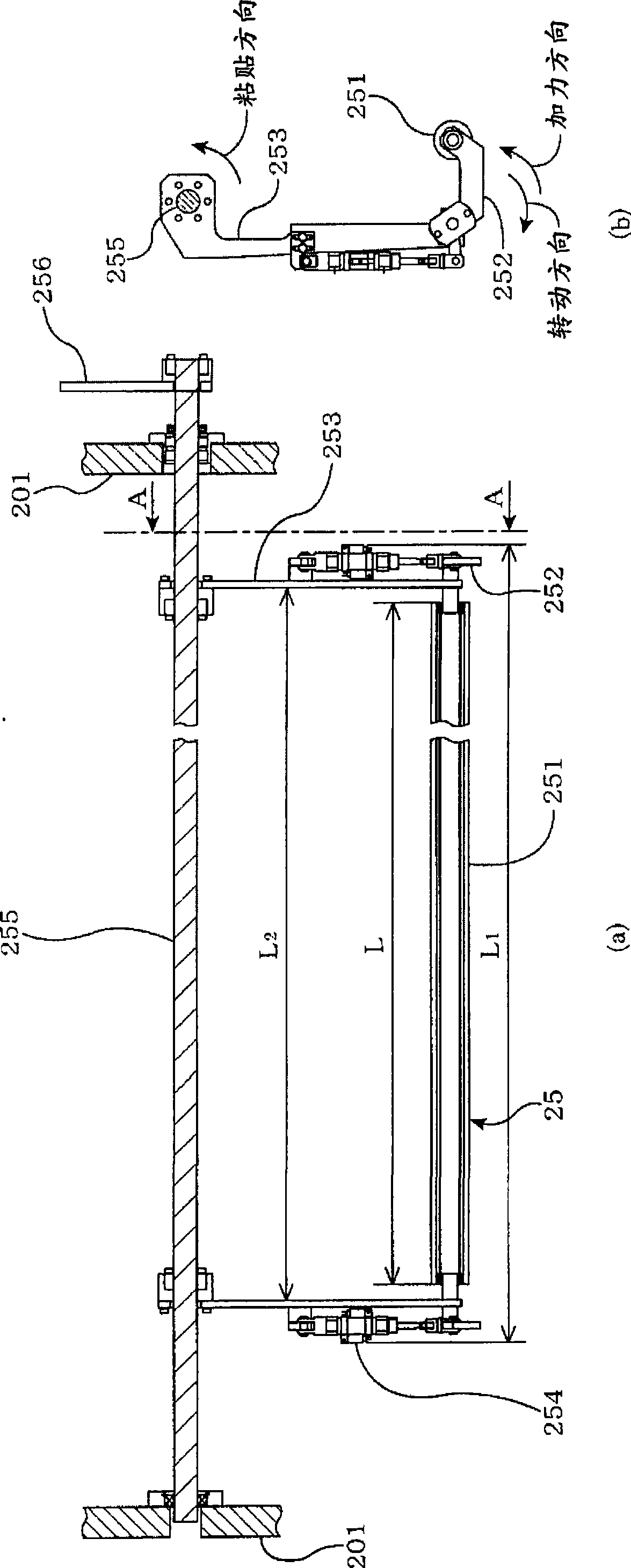

[0088] One embodiment of the slit-winding system and the automatic film winding device of the present invention will be described.

[0089] 【Cutting and winding system】

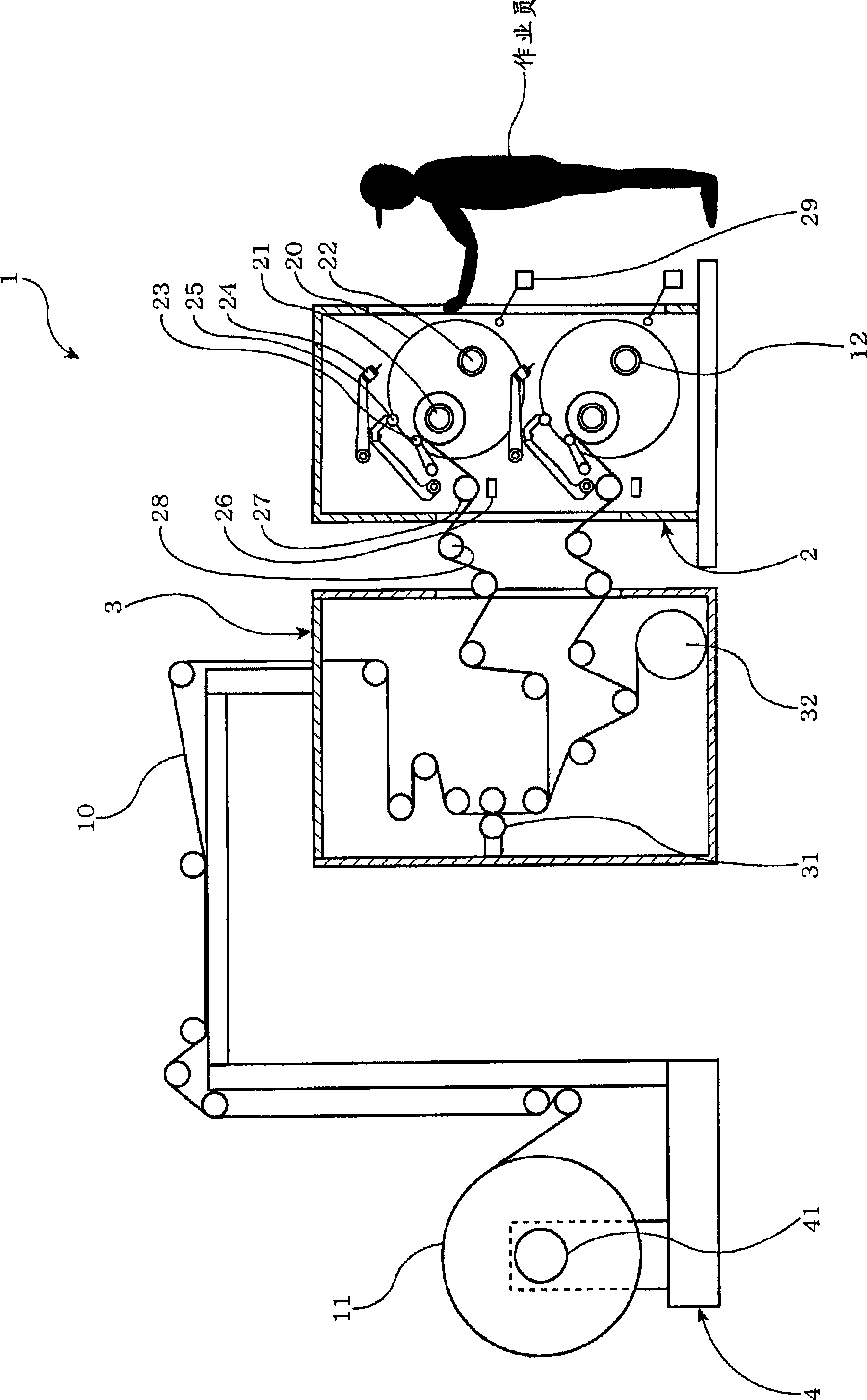

[0090] figure 1 It is a schematic cross-sectional view in the side direction showing a slit-and-wind system according to an embodiment of the present invention.

[0091] exist figure 1 Among them, the slitting and winding system 1 includes an automatic film winding device 2 and a slitting machine 3 . Moreover, the automatic film winding device 2 is connected with the roll film (original reverse) output device 4 .

[0092] The roll film output device 4 has an output shaft 41 on which the roll film 11 is attached, and supplies the film 10 to the slitter 3 . The slitter 3 has a cutting unit 31 that cuts the film 10 from the roll film output device 4 into a predetermined width, and an edge winding unit 32 that winds the edge of the film 10 . The slitter 3 supplies the cut film 10 to the automatic film windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com