Winding forming method for double-layer composite material of rotator

A winding molding and composite material technology, which is applied in the field of rotating body double-layer composite material winding molding and rotating body molding, can solve the problem of easy slippage of inner layer materials, and achieve the effect of improving the internal and external quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 of the present invention comprises the following steps:

[0024] 1. Preparation steps:

[0025] Prepare a metal mold. The metal mold is a rotating body, which is sequentially composed of an integral transition section, a profile, an extension section, a flange and a mandrel. The profile is consistent with the internal profile of the product to be formed, which is a truncated cone, θ is 25°; the transition section is cylindrical, and the extension section is spliced by a truncated conical shape and a cylindrical shape; the material of the metal mold is alloy steel 30CrMnSiA, which meets the requirements of a temperature below 200°C and a pressure of 4 to 5MPa, and the use of 500 There is no deformation for more than one hour, and the total axial length of the metal mold surface and extension section is 200mm;

[0026] Dip the carbon fiber cloth and high silica fiber cloth into the same phenolic resin to prepare the inner layer prepreg cloth and the outer ...

Embodiment 2

[0030] Embodiment two of the present invention comprises the following steps:

[0031] 1. Preparation steps:

[0032] Prepare a metal mold. The metal mold is a rotating body, which is sequentially composed of an integral transition section, a profile, an extension section, a flange and a mandrel. The profile is consistent with the shape of the internal profile of the product to be formed, and is a curved surface of revolution, θ 26°~24°; the transition section is in the shape of a truncated cone, and the extension section is spliced by a truncated cone and a cylinder; the material of the metal mold is 20# steel, which meets the requirements of a temperature below 200°C and a pressure of 4-5MPa , use for more than 500 hours without deformation, the total axial length of the metal mold surface and extension section is 1200mm;

[0033] Dip carbon fiber cloth and quartz fiber cloth into the same phenolic resin to prepare inner layer prepreg cloth and outer layer prepreg cloth; ...

Embodiment 3

[0037] Embodiment three of the present invention comprises the following steps:

[0038] 1. Preparation steps:

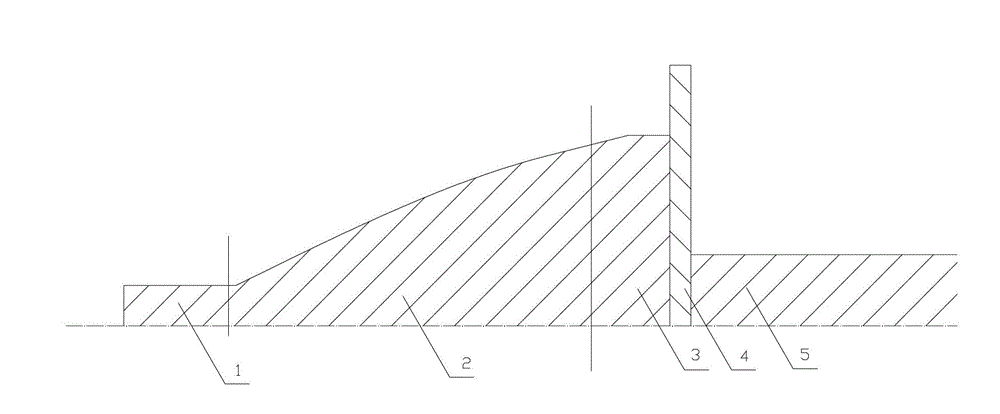

[0039] Prepare metal molds such as figure 1 As shown, the metal mold is a rotating body, which is sequentially composed of an integrated transition section 1, profile 2, extension section 3, flange 4 and mandrel 5, and the profile 2 is consistent with the shape of the inner profile of the product to be formed. It is a curved surface of revolution, θ is 26.1°~23.7°; the transition section 1 is cylindrical, and the extension section 3 is spliced by frustum-shaped and cylindrical; the material of the metal mold is 20# steel, which meets the requirements of Below ℃, pressure 4~5MPa, use for more than 500 hours without deformation, the total axial length of the mold surface and extension section is 500mm;

[0040]Dip carbon fiber cloth and non-alkali glass fiber cloth into the same phenolic resin to prepare inner prepreg cloth and outer prepreg cloth; the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com