Guide rail device and method for omnidirectional directional blasting charge

A technology of directional blasting and guide rail device, which is applied in blasting and other directions, can solve the problems of not solving the problem of directional charging of large-angle blastholes, limiting the popularization and application of cutting and caving technology, and not solving the problem of anti-slip of the charge coil, so as to improve the blasting effect, The effect of reducing the amount of charge and increasing the efficiency of the charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the accompanying drawings.

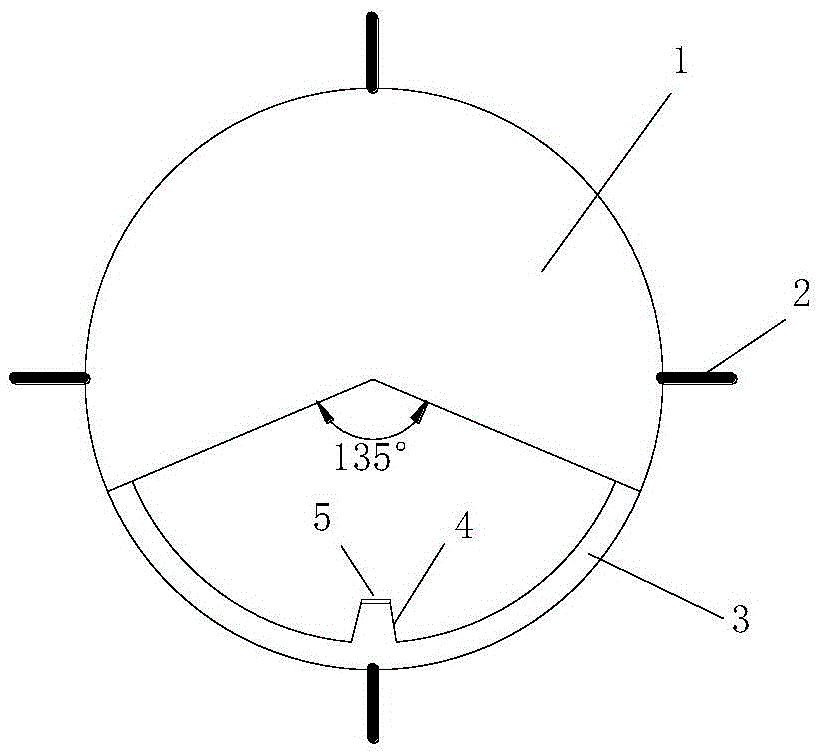

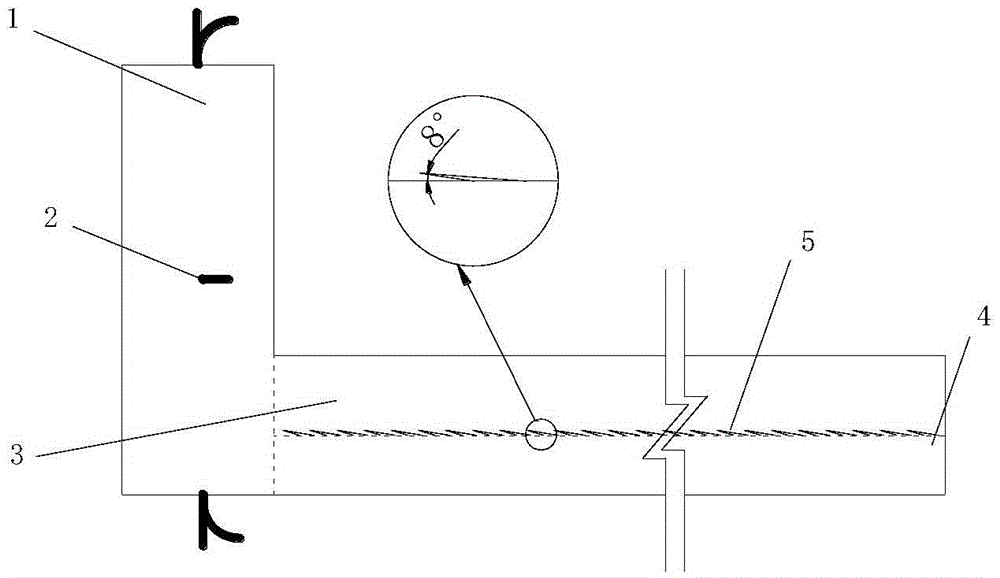

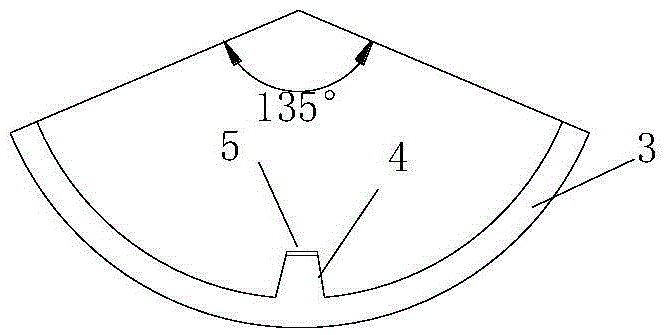

[0034] The invention relates to a guide rail device and a method for omnidirectional directional blasting charge. The guide rail device is composed of the first section guide rail connected with several common guide rails. Anti-skid wires are installed at the end of the first section guide rail. There is a longitudinal ridge in the middle of the medicine roll pushing track of the guide rail. A hook hole is provided at the end of the upper guide rail, and a metal hook is provided at the head end of the lower guide rail, and the connection of the guide rails is realized through the connection of the metal hook and the hook hole. The guide rail device is composed of the first section guide rail connected with several common guide rails. Anti-skid wires are installed at the end of the first section guide rail. There is a longitudinal ridge in the middle of the medicine rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com