Novel refrigerator side panel splicing structure

A side panel and freezer technology, which is applied in the field of new type freezer side panel splicing structure, can solve the problems of easy sliding of side panels, troublesome production, waste of manpower, time and money, etc., and achieves the reduction of the number of components, the solution to the sliding problem, and the convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

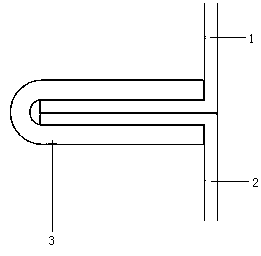

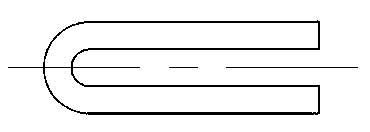

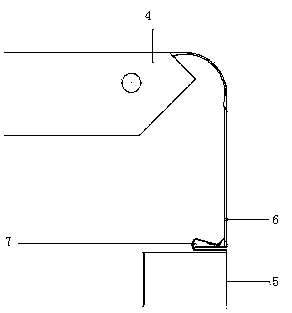

[0016] figure 1 and figure 2 The splicing of the front panel and the side panel of the refrigerator in the prior art is shown. Such as figure 1 As shown, the splicing of the prior art is fixed by inserting strips, and the front panel 1 and the side panel 2 are clamped together by the box shell fillet 3, so as to fix the front panel 1 and the side panel 2. This splicing process involves parts The quantity and steps are many, which brings unnecessary troubles to production and wastes manpower, time and money. The structure of box shell fillet 3 is as follows figure 2 As shown in the figure, it can be seen that the structure of this kind of case molding is simple and smooth. When it is combined with the edge of the panel, there will be gaps between the parts, the splicing is not reliable, and the side panel is easy to slide. Therefore according to existin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com