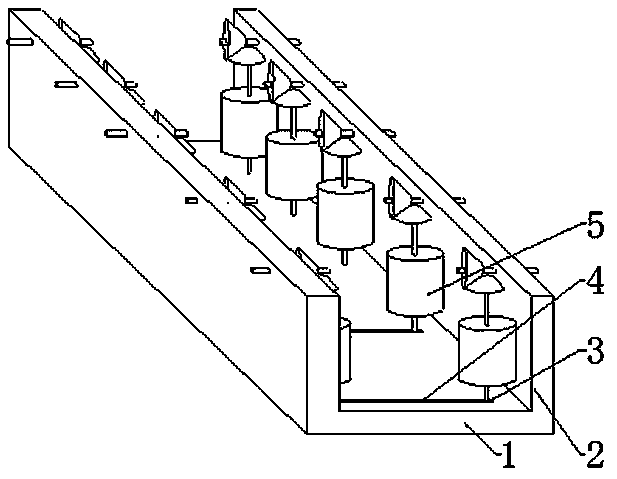

A metal material straightening machine

A metal material, straightening machine technology, applied in the field of metal material straightening machine, can solve the problems of inconvenient operation, inaccurate working parameters, poor adaptability of metal workpieces, etc., to improve stability and work efficiency, wide application range, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

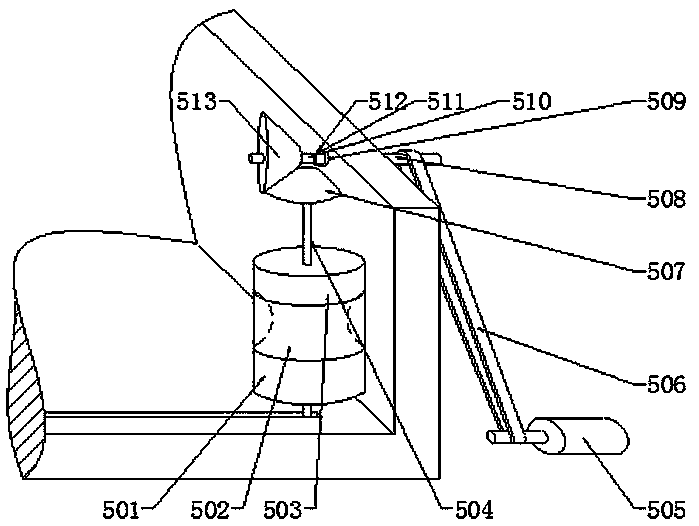

[0024] Specific embodiments: when the operator uses the present invention, the operator measures the size of the object to be aligned, and installs the gear shaft 511 on the drive shaft 508 according to the size of the object to be aligned. The size of the object is determined by observing the scale on the gear shaft 511 to determine the installation position of the gear shaft 511. After the position is determined, the positioning pin 512 is fixed in the positioning hole 510, and the installation of the bevel gear 2 513 is completed. Metal materials of different sizes are straightened, which solves the shortcoming of the narrow application range of the straightening machine.

[0025] After completing the installation of bevel gear 2 513, the operator judges whether the straightening object is a hollow shaft, and if it is a hollow shaft material, install the arc-shaped roller 502 on the upper end of the lower roller 501, and then install the upper roller 503 on the arc-shaped ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com