Inclined winding type coreless coil winding device

A technology of winding equipment and hollow cups, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of high maintenance costs, cumbersome operations, and complex structures, so as to improve work quality and efficiency, and improve Winding quality, effect of simplified complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

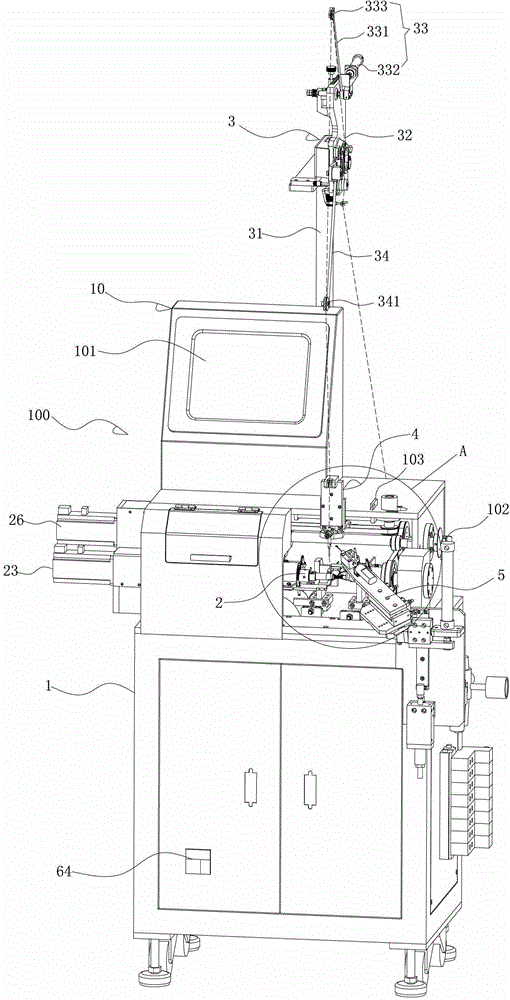

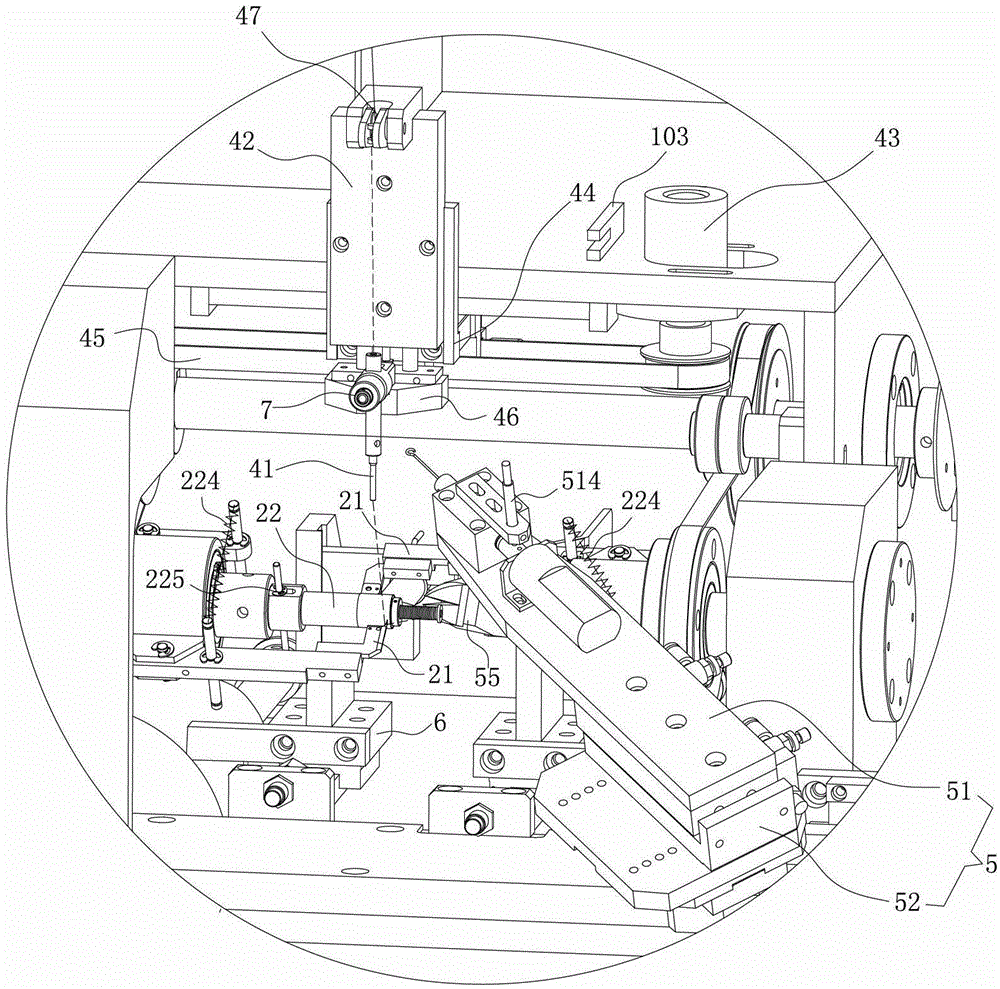

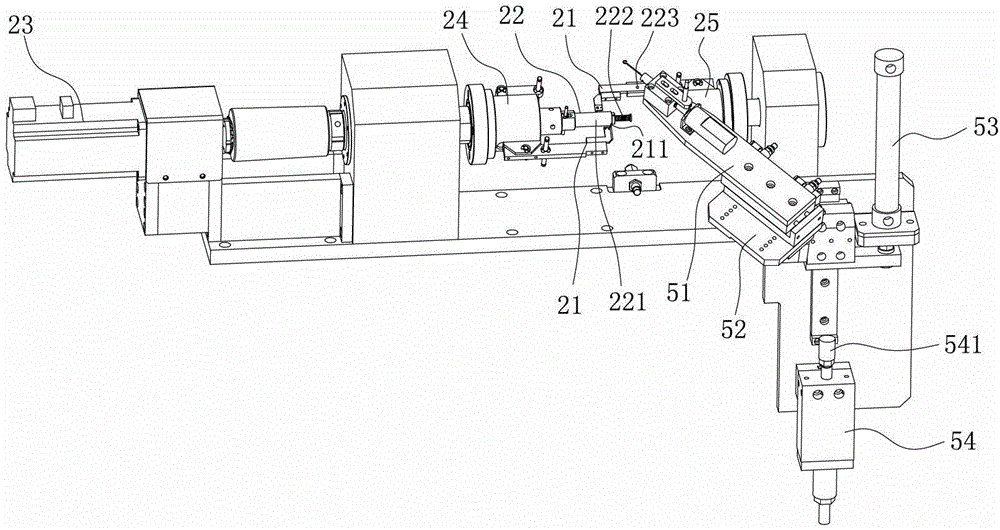

[0057] see Figure 1-7 As shown, the skew-wound coreless coil winding equipment includes: a winding equipment 100 .

[0058] The winding device 100 includes: a chassis 1, a winding mechanism 2 installed on the chassis 1, a wire feeding mechanism 3 located above the winding mechanism 2, a winding mechanism 4, and a winding mechanism installed on the side of the winding mechanism 2 Stranded wire integration mechanism 5 and first heater 6 .

[0059] An electrical control system 10 for controlling the operation of the winding mechanism 2, the wire feeding mechanism 3, the wire arranging mechanism 4, and the twisted wire integration mechanism 5 to eliminate movement errors is installed in the cabinet 1, wherein the electrical control system The touch screen 101 of 10 is exposed on the chassis 1 . The present invention controls the actions of the wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com