Elevator long object hook detection device

A detection device and a technology for long objects, which are used in transportation and packaging, elevators, etc., and can solve problems such as difficult detection of hooks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

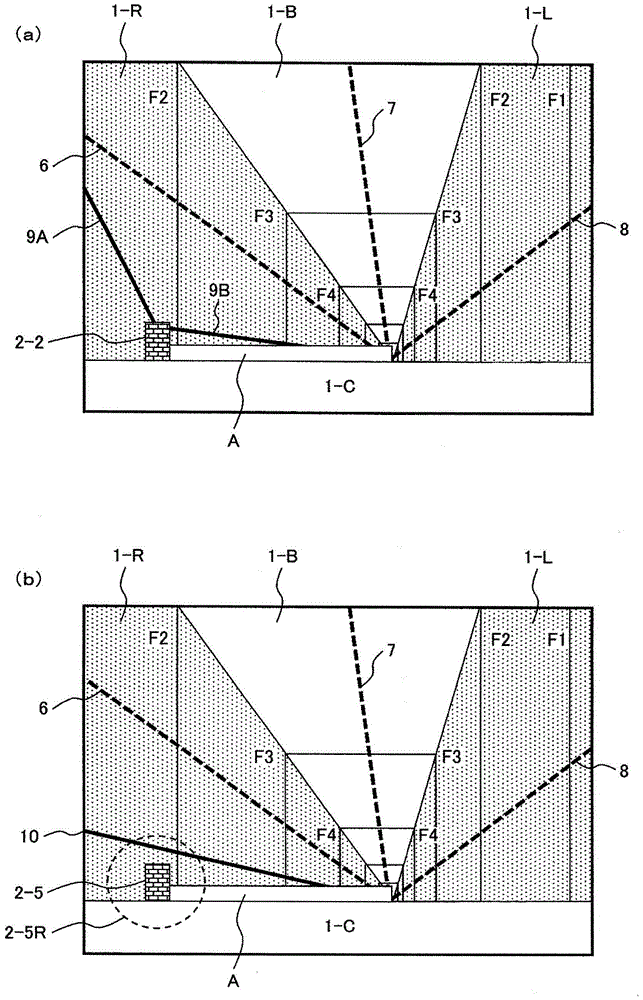

[0082] [Principle Description]

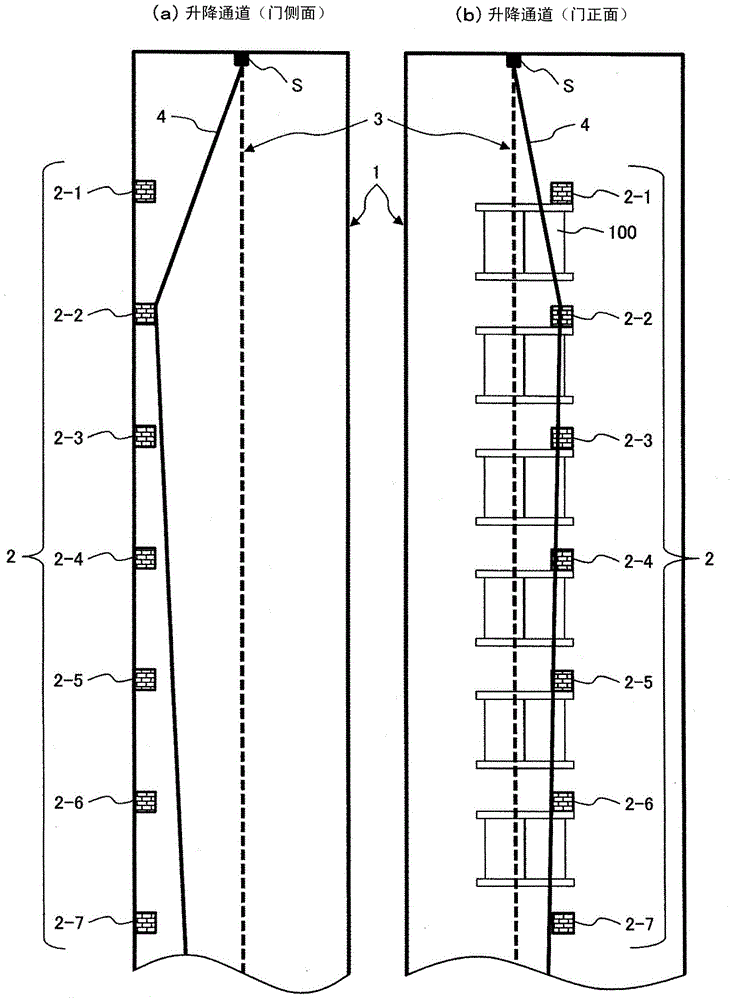

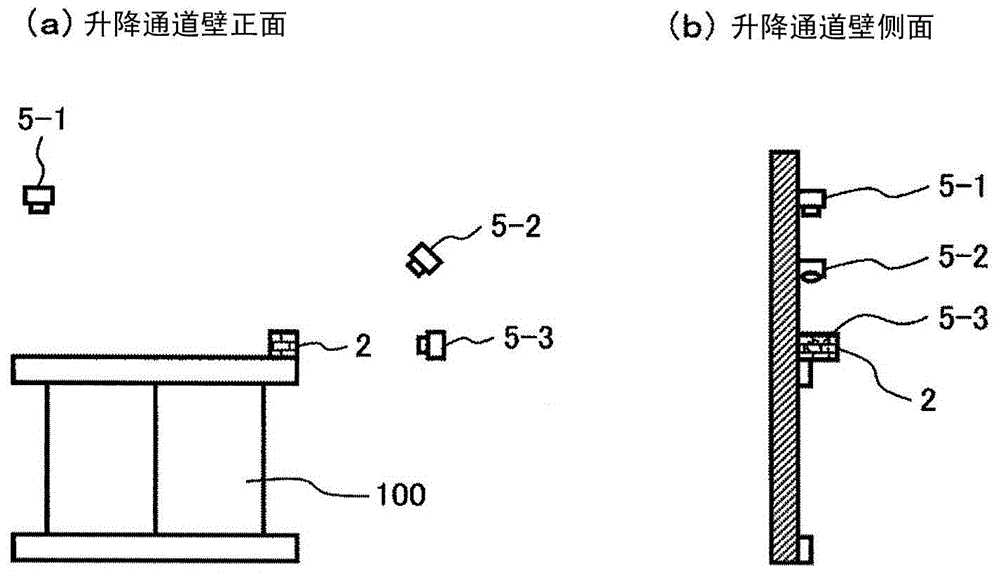

[0083] figure 1 Indicates the state that the rope is hooked on the protrusion in the hoistway. figure 1 (a) is a view of the interior of the elevator hoistway 1 viewed from the side of the elevator hall door 100, figure 1 (b) is the figure which looked at the inside of this hoistway 1 from the front side direction of the elevator hall door 100. As shown in FIG. The top of the elevator car of the elevator is provided with a stop floor detection device (not shown), which is a magnetic sensor or a photoelectric sensor. Furthermore, on the side of the hoistway, a shielding panel 2 (the specific structure is not shown) is attached to the upper part of the door of each floor. As far as the shielding boards 2 (2-1 to 2-7) are concerned, when the elevator car of the elevator stops at any floor, the shielding boards 2 block the magnetism or light of the stop floor detection device, thereby detecting the elevator car. The stop or stop position of the...

Embodiment 2

[0130] Figure 13 It is a block diagram showing a long object hook detection device for an elevator as a second embodiment of the present invention.

[0131] In this embodiment, as the long object hooking detection parts 20-1, 20-2, ..., 20-n (n is an integer greater than or equal to 2) shown in this figure, a plurality of Figure 8 The long object hook detection device 20 of the elevator is shown. Each imaging unit that the long object hooking detection unit 20-1, 20-2, ..., 20-n possesses is installed in a manner to bring the shielding panels 2 of different floors into the field of view respectively (refer to figure 2 ). The outputs of the long object hooking detectors 20 - 1 , 20 - 2 , . And, when the output of the vibration sensor 45 is input to the activation unit 46, the activation unit 46 activates the long object hook detection units 20-1, 20-2, . . . , 20-n and the elevator car stop floor determination unit 47.

[0132] First, the vibration sensor 45 outputs an o...

Embodiment 3

[0135] Figure 14 It is a block diagram showing a long object hooking detection device for an elevator as a third embodiment of the present invention.

[0136] The long object hook detection device 50 of the elevator of the present embodiment includes an imaging unit 5, a three-dimensional distance sensor 51, a setting tool 21, an area image holding unit 25, a time averaging unit 26, a rope detecting unit 27, and a direction measuring unit 28. , a distance measurement unit 29 , a hook presence / absence determination unit 30 , and a determination result output unit 31 . It should be noted that, in the long object hook detection device 50 of the elevator, with Figure 8 The processing functions of the blocks with the same symbols in the processing blocks of the long object hooking detection device 20 of the elevator are also the same.

[0137] The three-dimensional distance sensor 51 can be a device capable of detecting distance in the depth direction, such as a stereo camera o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com