Blocking cable lifting device

A lifting device and arresting cable technology, which is applied to ground devices, parking devices, transportation and packaging, etc., can solve the problems of no civil aircraft arresting cable system, personal and property damage, and aircraft rushing out, so as to improve combat performance, Ease of installation and maintenance, added safety benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

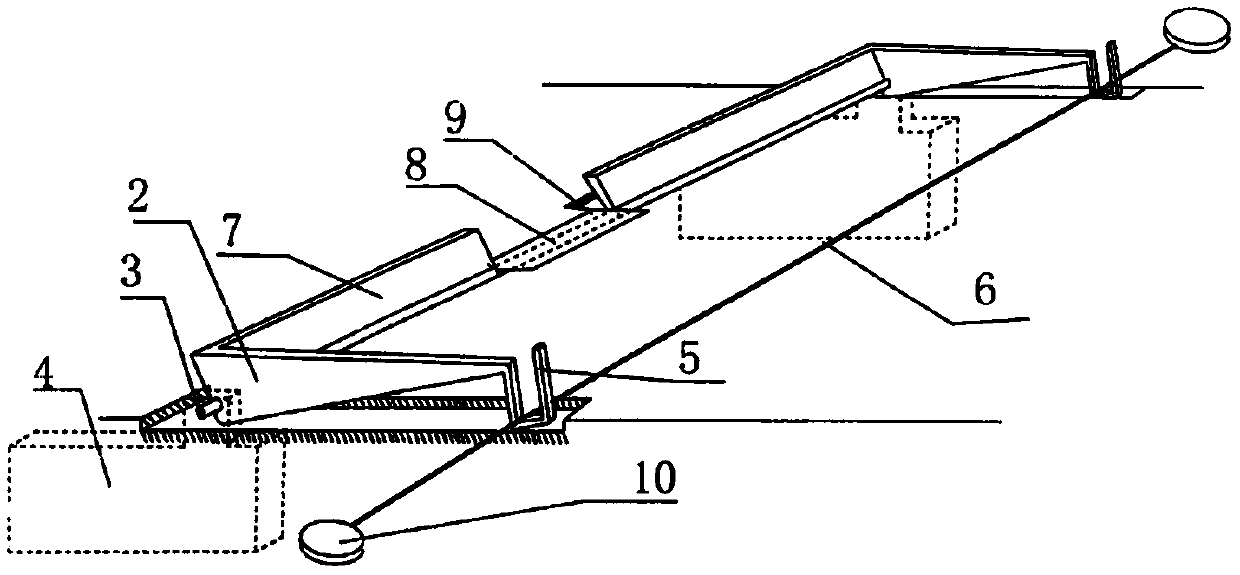

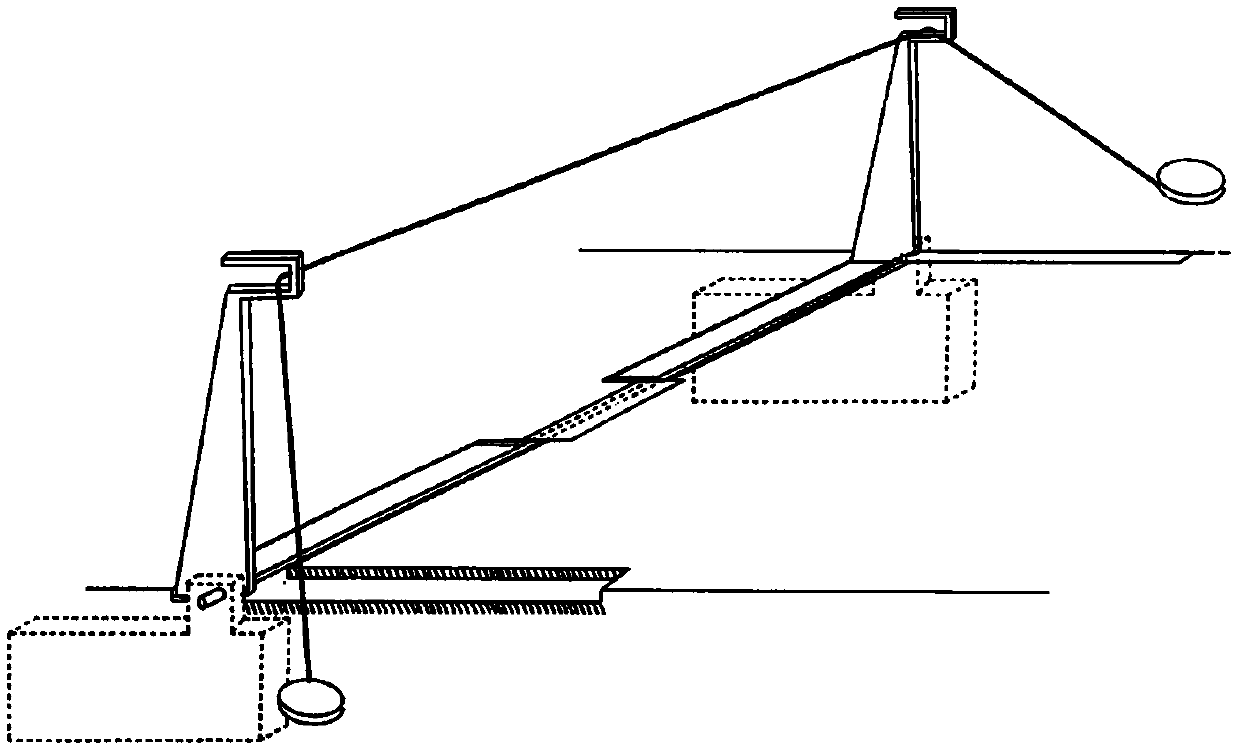

[0029] Such as figure 1 , figure 2 As shown, this is an arresting cable system using a tail hook-type arresting cable lifting device, including a trigger plate (7) with a notch welded on a long axis (3), and a hanging arresting plate welded at each end. The rocking arm (2) of the draw-in groove (5) of cable (6), the included angle of the trigger plate (7) with notch and rocking arm (2) is 110 degree. The major axis (3) is hinged on the shaft seat (4) fixed on the airstrip.

[0030] The major axis (3) spans the airstrip below the airstrip floor.

[0031] There is a gap in the middle of the trigger plate (7) with a gap for the passage of the front wheel. The gap is 2 meters wide. The trigger plate (7) is slightly tilted forward. The trigger plate (7) with notch is 30 centimeters high. Grooves are arranged at the corresponding positions where the notched trigger plate (7) is pressed down on the runway.

[0032] The upper edge of the card slot (5) is longer than the lower e...

Embodiment 2

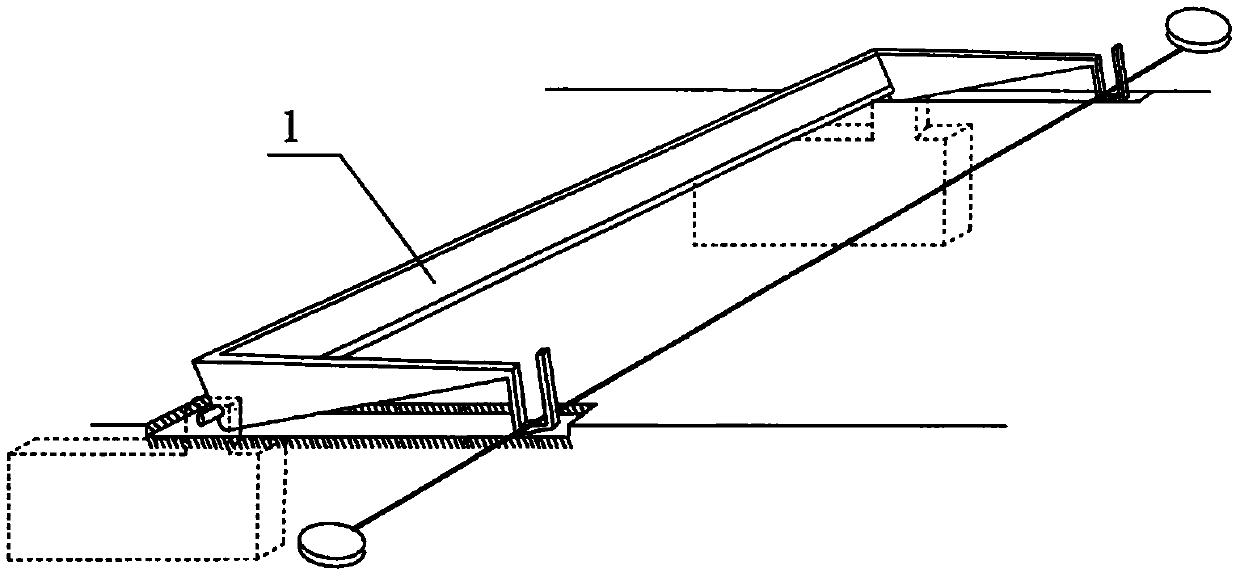

[0036] Such as image 3 , Figure 4 As shown, this is an arresting cable system that adopts the rear landing gear type arresting cable lifting device. In this embodiment, the basic structure is the same as that in Embodiment 1, and the special features are as follows:

[0037] In this embodiment, there is no gap in the middle of the trigger plate (1). When the aircraft lands, the front wheel rolls over the trigger plate (1), which drives the rocker arm (2) to rotate synchronously, and the arresting cable (6) is held up and provided to the rear landing gear.

[0038] After the aircraft lands, it travels to the lifting device of the rear landing gear type arresting cable, the front wheel rolls the trigger plate (1) to drive the rocker arm (2) to rotate, lifts the arresting cable (6), and provides it to the rear landing gear hook Hold, make the arresting cable system play a role, and realize safe landing.

[0039] This model can be installed on the runway hundreds of meters awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com