Three-needle parallel winding and blocked stator winding machine

A stator winding and winding mechanism technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of difficult to achieve automatic production, increase labor costs, wire ends need welding, etc., to provide winding efficiency, Reduced workload and high winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

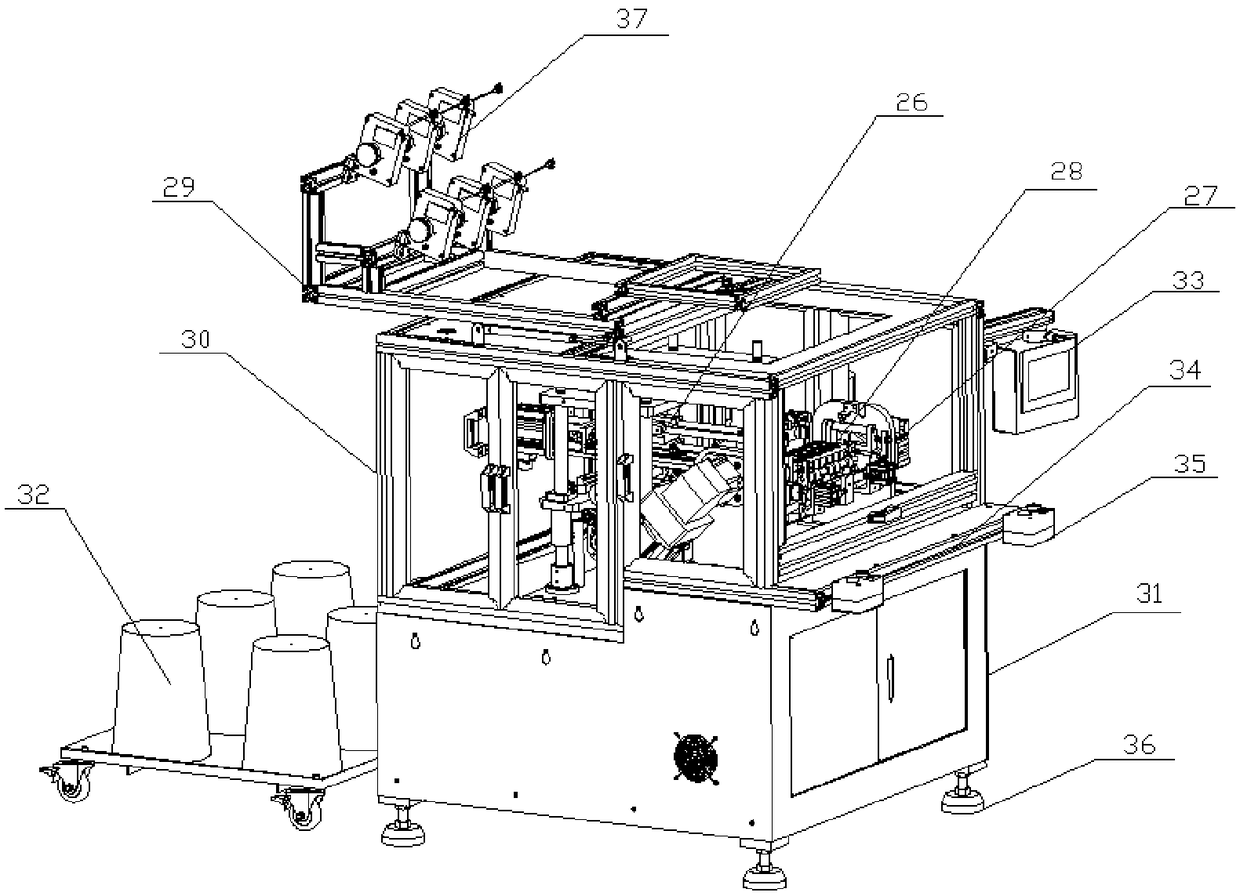

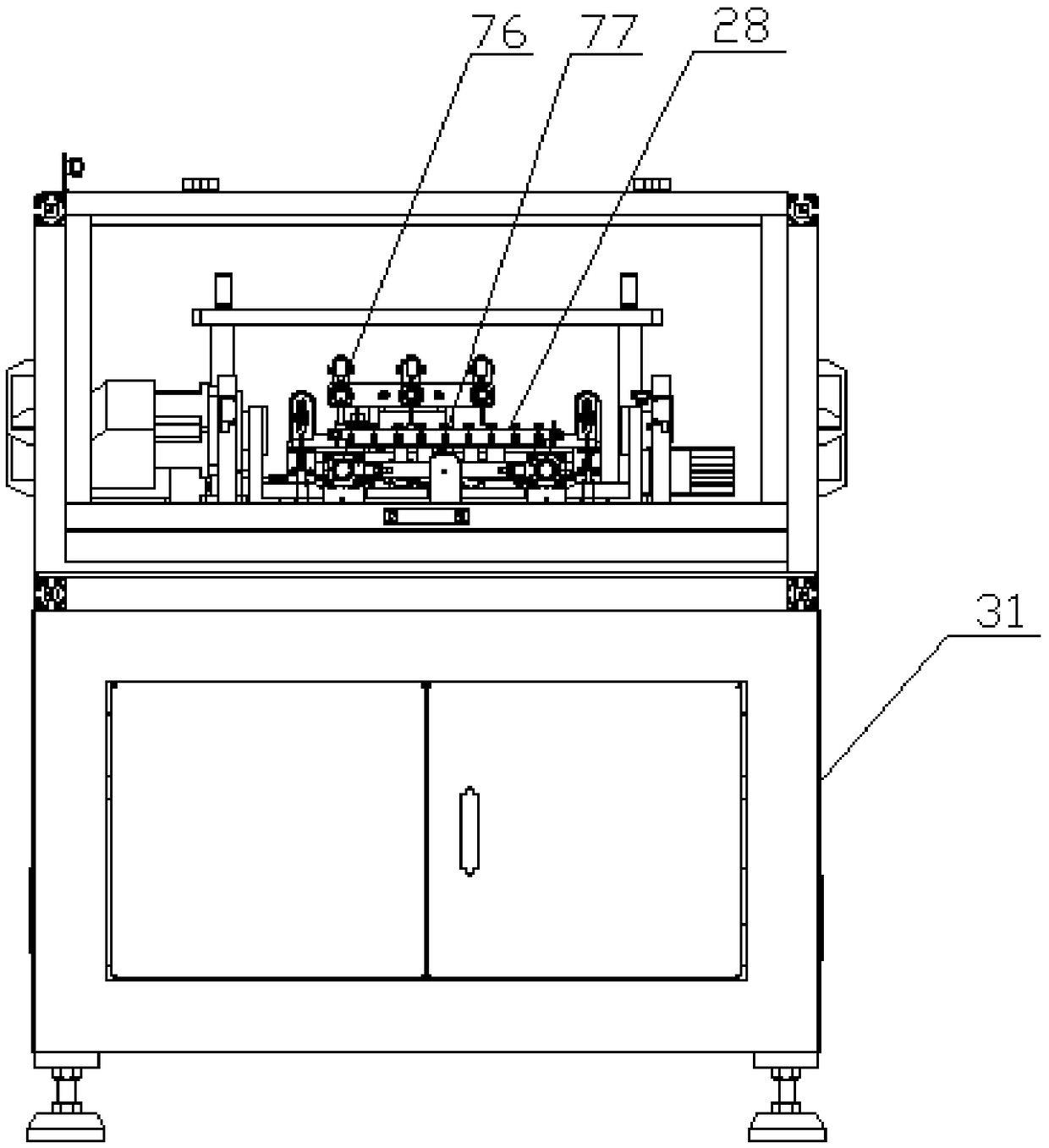

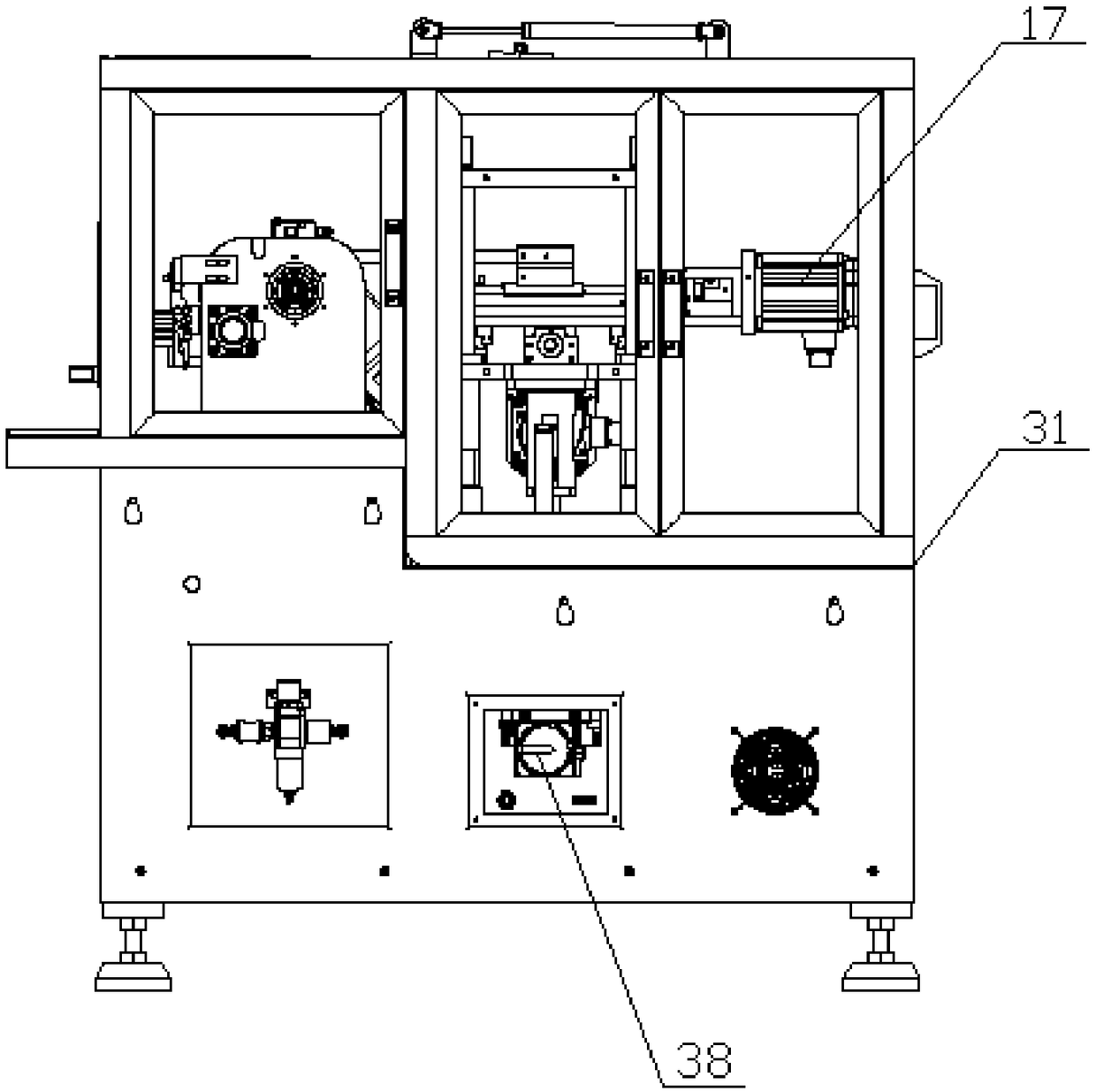

[0039] refer to Figure 1 to Figure 10 A three-needle parallel winding segmented stator winding machine is shown, including an equipment chassis 31, a three-dimensional winding mechanism 26, a segmented stator placement fixture 28, a tensioner main body 37, a safety protection cover 30, and a thread trimmer 77 , clamping device 75, turning table 27, winding device 76 and man-machine interface 33, described three-dimensional winding mechanism 26 is installed on the upper end of equipment chassis 31, and winding device 76 is installed on the front of three-dimensional winding mechanism 26 In the front, the turning workbench 27 is installed on the upper end of the equipment chassis 31 and is positioned at the front of the three-dimensional winding machine 26. The thread trimming device 77 and the sub-block stator placement jig 28 are installed on the turning workbench 27. The thread cutting device 77 is located at the sub The block stator is placed at the lower end of the jig 28,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com