Production equipment and manufacturing method of antibacterial sound-insulation fabric

A production equipment and fabric technology, applied in the field of fabric production, can solve problems such as the unsatisfactory removal effect of fluff removal, the impact on the production quality of antibacterial and soundproof fabrics, and the complicated production process, so as to improve production quality, strong practicability, and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention;

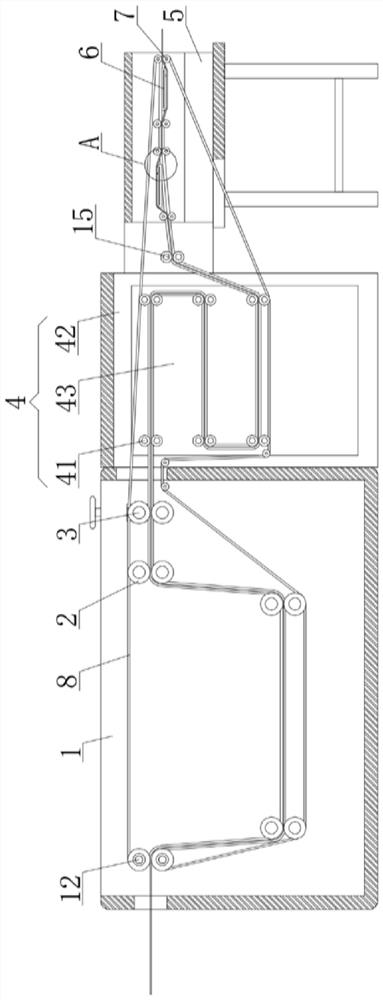

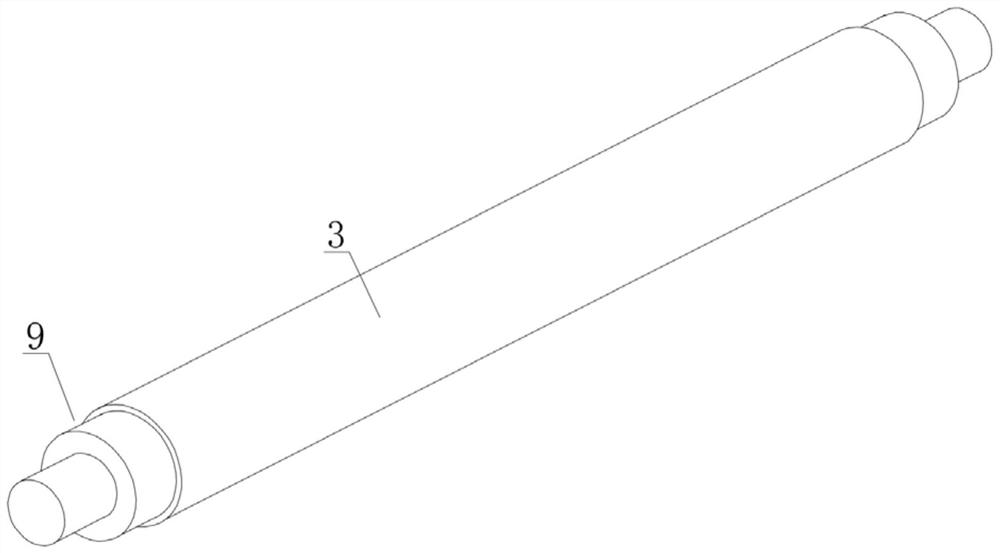

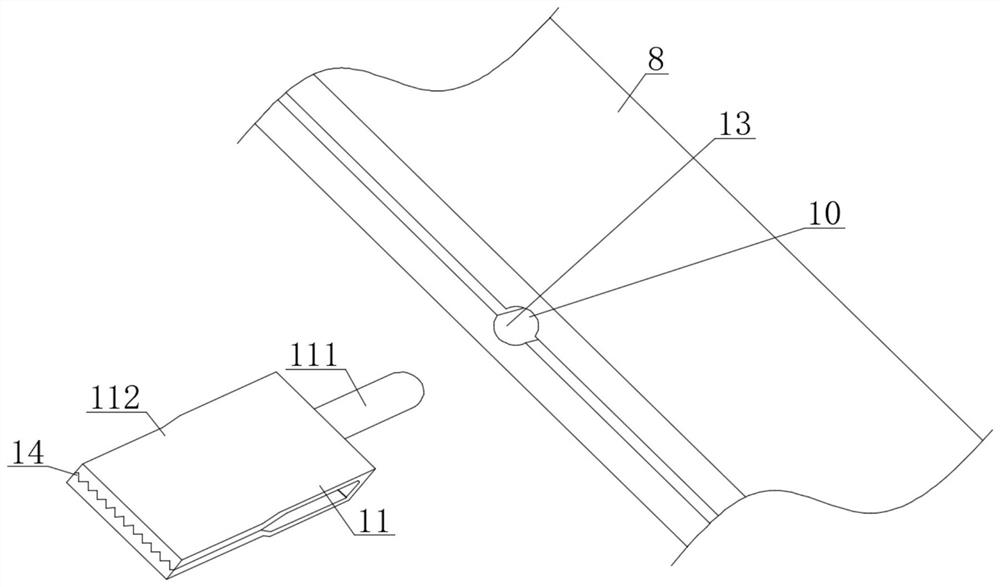

[0036] see Figure 1~4 , in the present invention, a kind of production equipment of antibacterial sound-proof fabric, comprises soaking box 1 and four guide conveyer belts 8, and the inside of soaking box 1 is connected with four sets of immersion guide rollers 2, and four sets of immersion guide rollers 2 are concave A set of dehydration rollers 3 is installed inside the dipping box 1, a drying mechanism 4 is arranged on the right side of the dipping box 1, and a fluff removal box 5 is arranged on the right side of the drying mechanism 4, and the interior of the fluff removal box 5 is fixedly installed. There are two ironing boards 6, two groups of adjustment rollers 7 are arranged on the left and right sides of the two ironing boards 6, and the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com