Paperboard pressing leveler

A flattening machine and cardboard technology, applied in the direction of mechanical processing/deformation, measuring devices, instruments, etc., can solve the problems of not being fine enough, only in the center position, affecting the use of cardboard strength and cardboard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

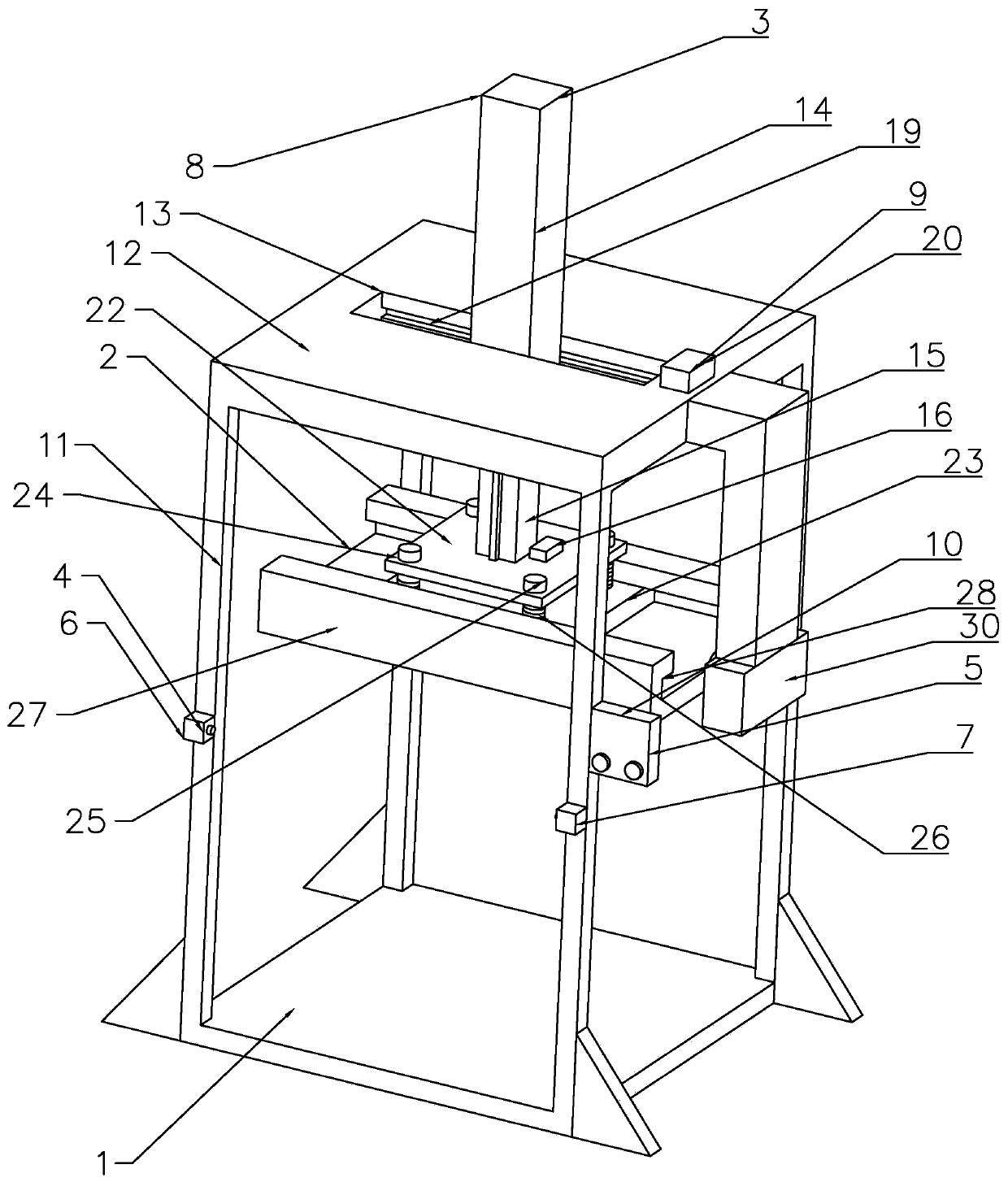

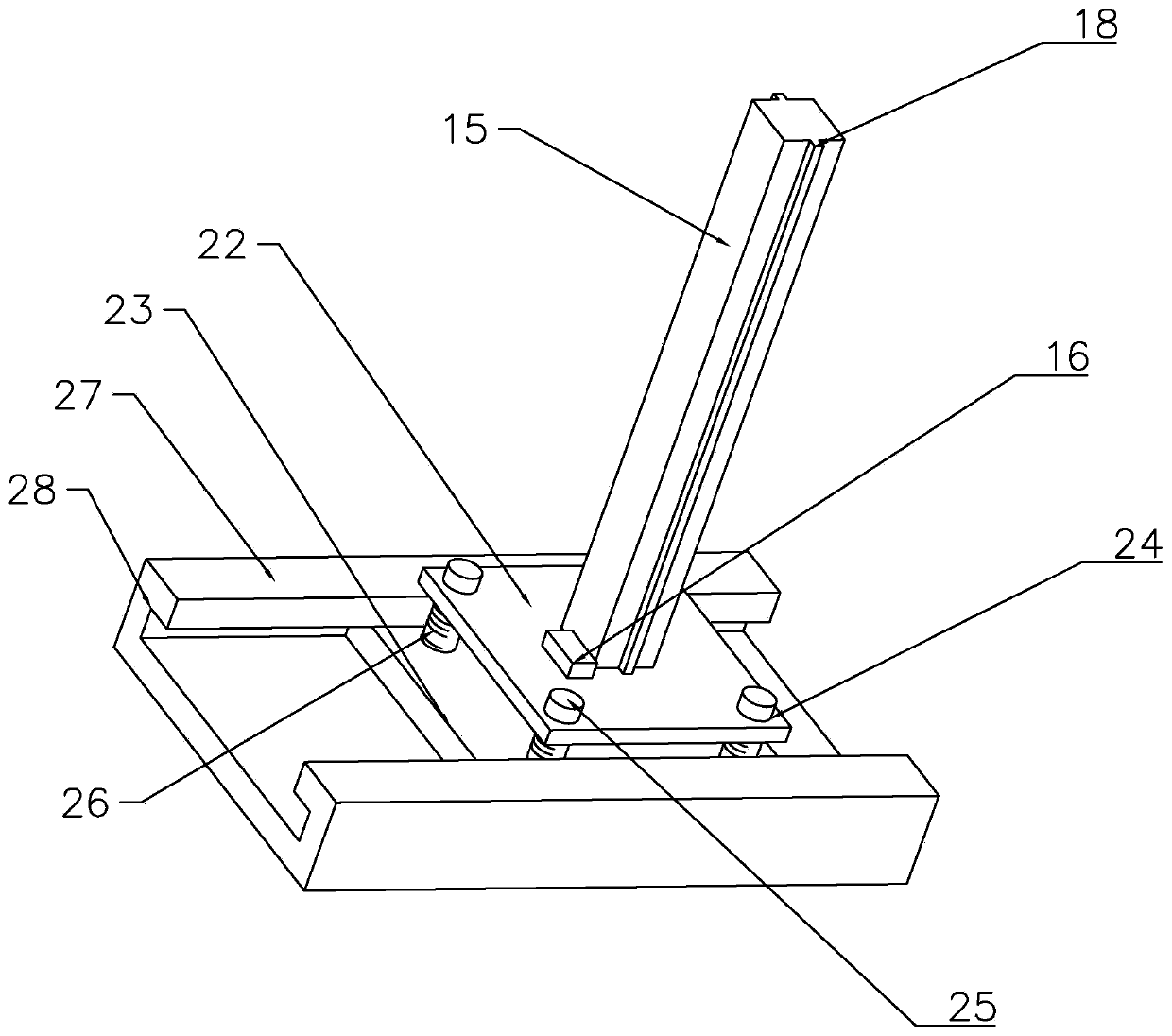

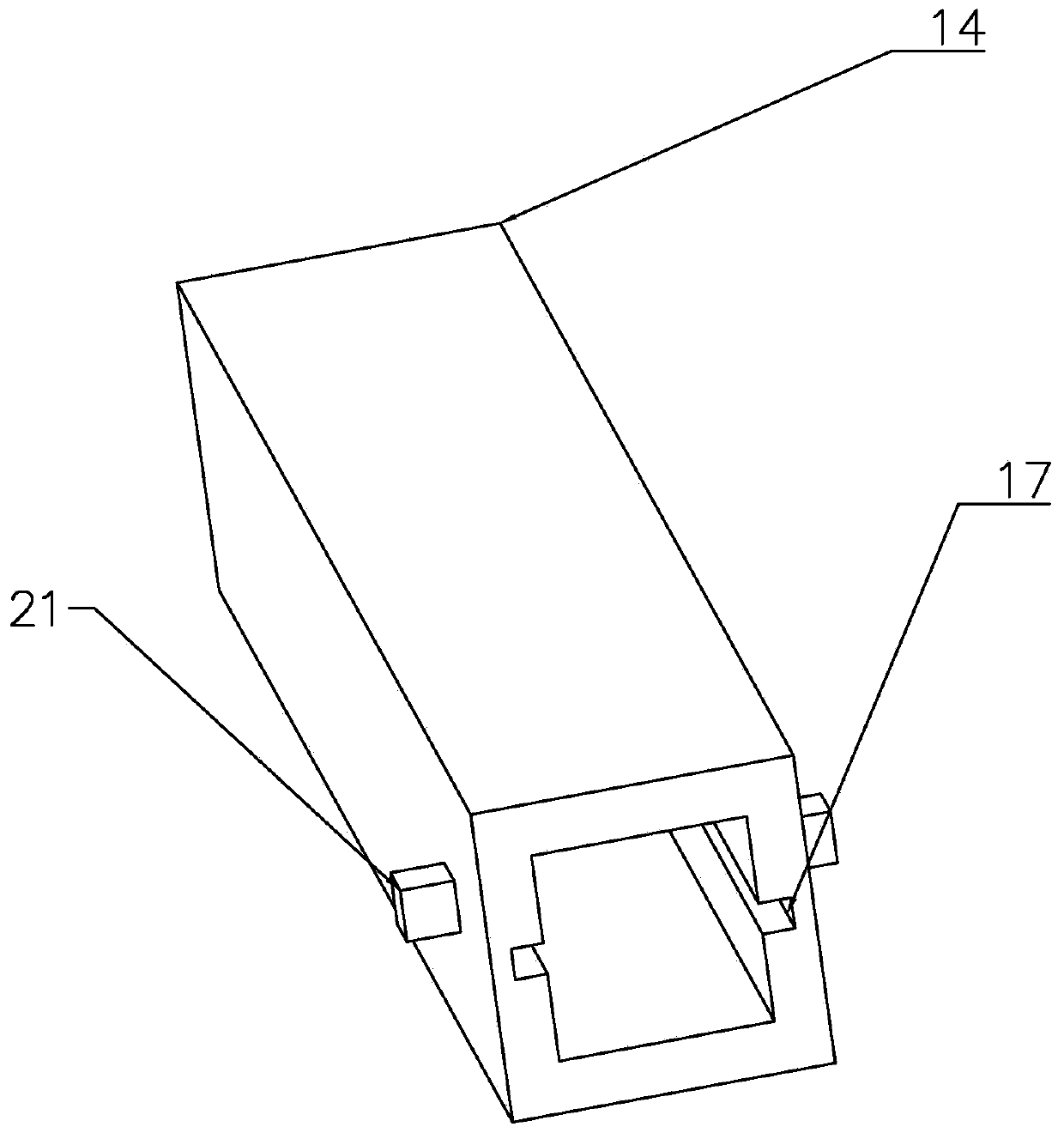

[0020] Such as Figure 1-4 As shown, a cardboard flattening machine includes an equipment base 1 for placing cardboard, said equipment base 1 is provided with a flattening plate 2 for flattening cardboard, and a sliding device 3 for assisting the sliding of the flattening plate 2 , a detection device 4 for measuring the straightness of cardboard and a control device 5 for controlling the movement track of the pressing plate 2, the detection device 4 includes an infrared emitting element 6 and an infrared receiving element 7, and the infrared emitting element 6 and the infrared receiving element The elements 7 remain on the same level, the sliding device 3 includes a sliding rod 8 and a driving motor 9 for driving the sliding rod 8 to slide downward, the sliding rod 8 is connected with the pressing plate 2, and the control device 5 includes a driving motor 9 for driving the sliding rod 8 to slide downward. The control cabinet 10 for controlling the operation of the driving moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com