Pop can quick flattening equipment

A kind of pop-top cans, fast technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of not meeting people's use needs, affecting people's normal use, and slow flattening efficiency, so as to improve the flattening efficiency, simple structure, and meet the use needs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

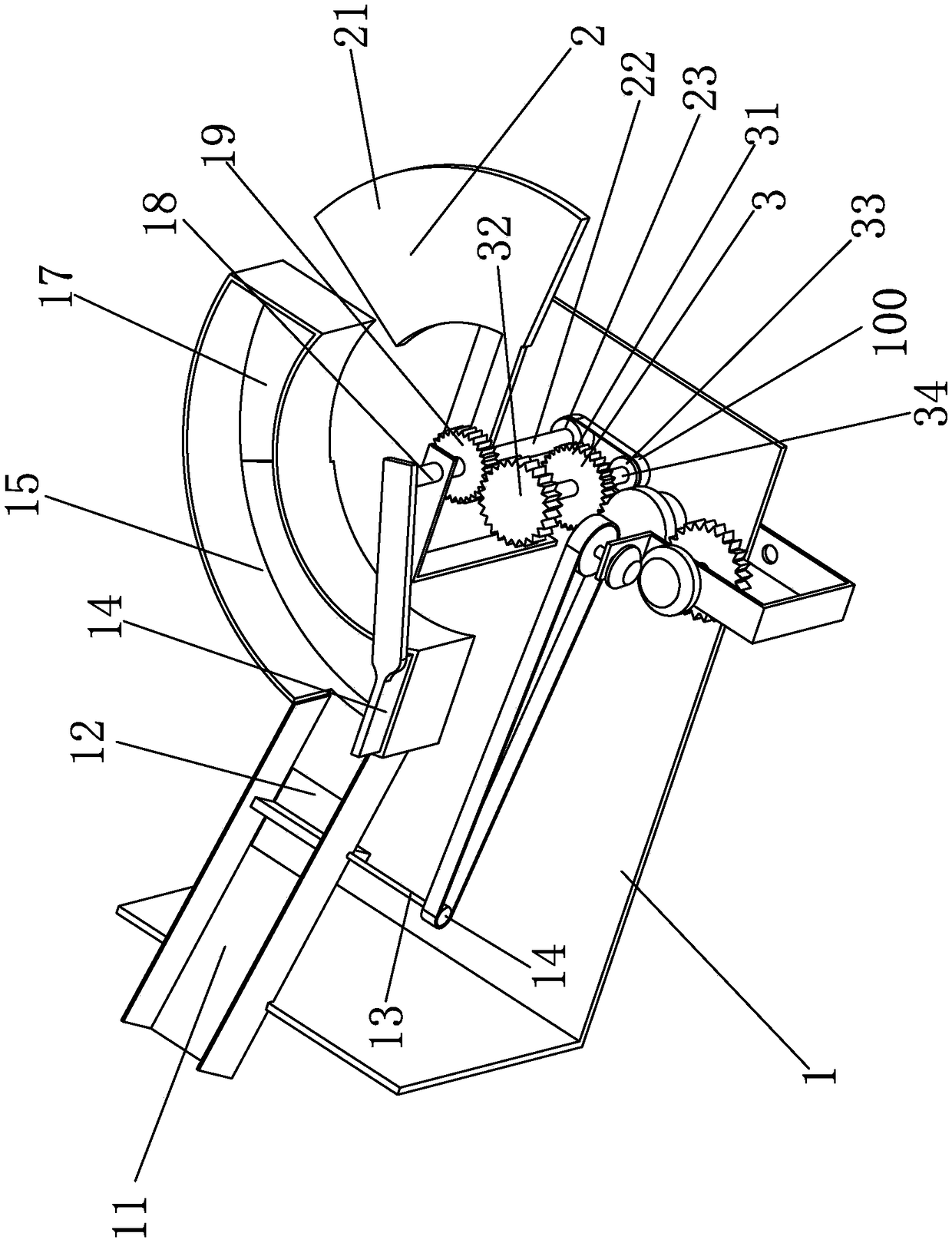

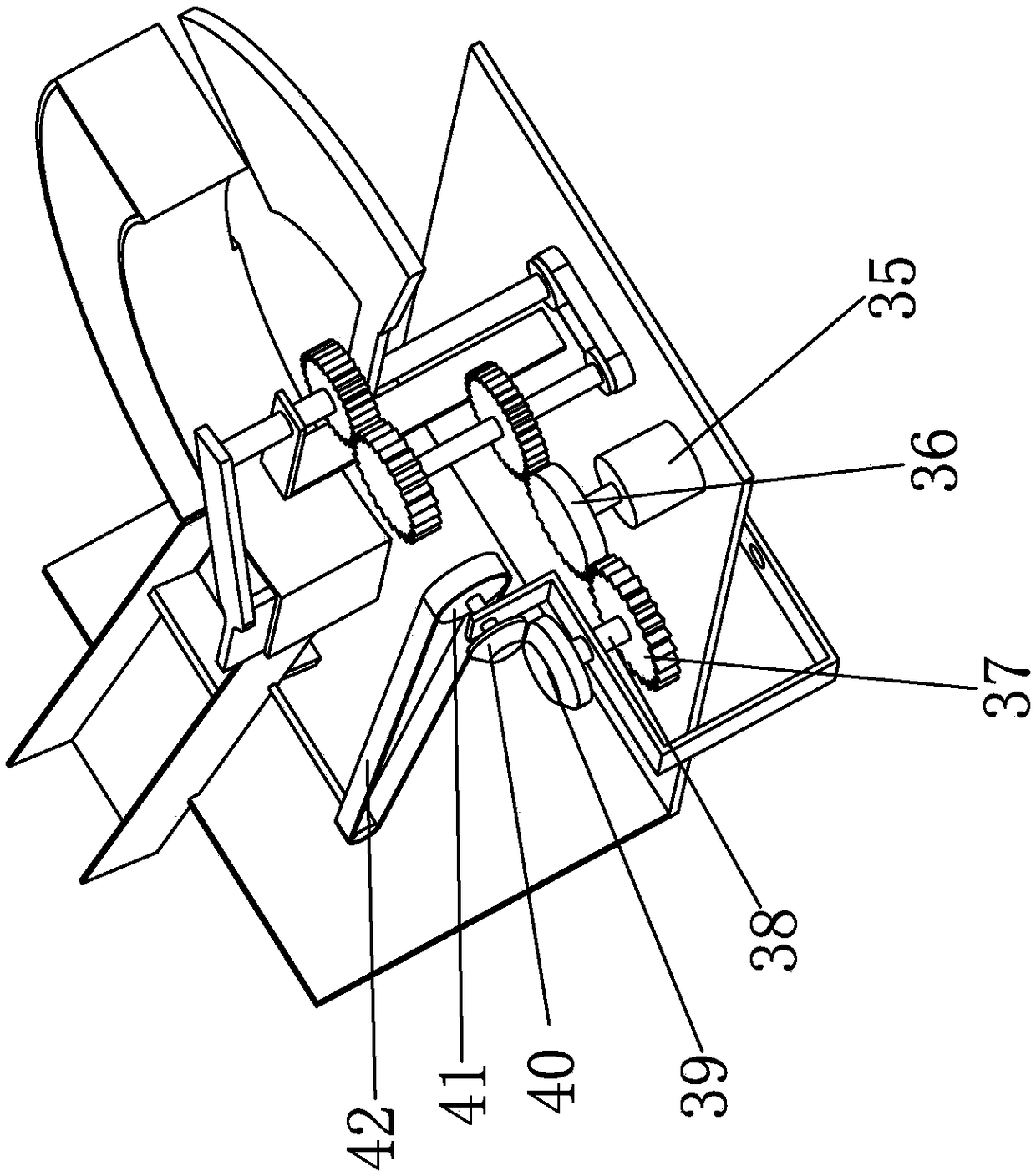

[0014] Such as Figures 1 to 2 A quick flattening device for pop cans shown includes a base 1, on which a conveying track 11 is arranged, on which a first through groove is arranged, and in the first through groove A cross turning plate 12 is inserted through the first rotating shaft 13, and an arc track 15 is communicated with the front end of the conveying track 11, and a second through groove 17 is provided on the bottom surface of the front end of the arc track 15. The lower end of the track 15 is provided with a closing device 2 capable of closing the second through groove 17. On the arc track 15, a pressing plate 14 that can push the pop can and flatten it is provided. The pressing plate 14 is inserted through the third rotating shaft 18. Connected to the base 1, the base 1 is equipped with a cross turning plate 12 that can drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com