Scrap iron recovery device for automobile part machining

A technology for auto parts and recycling devices, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of inability to compress and recycle iron scraps, laborious, and occupy a large space, so as to improve the flattening efficiency, The effect of preventing rebound and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

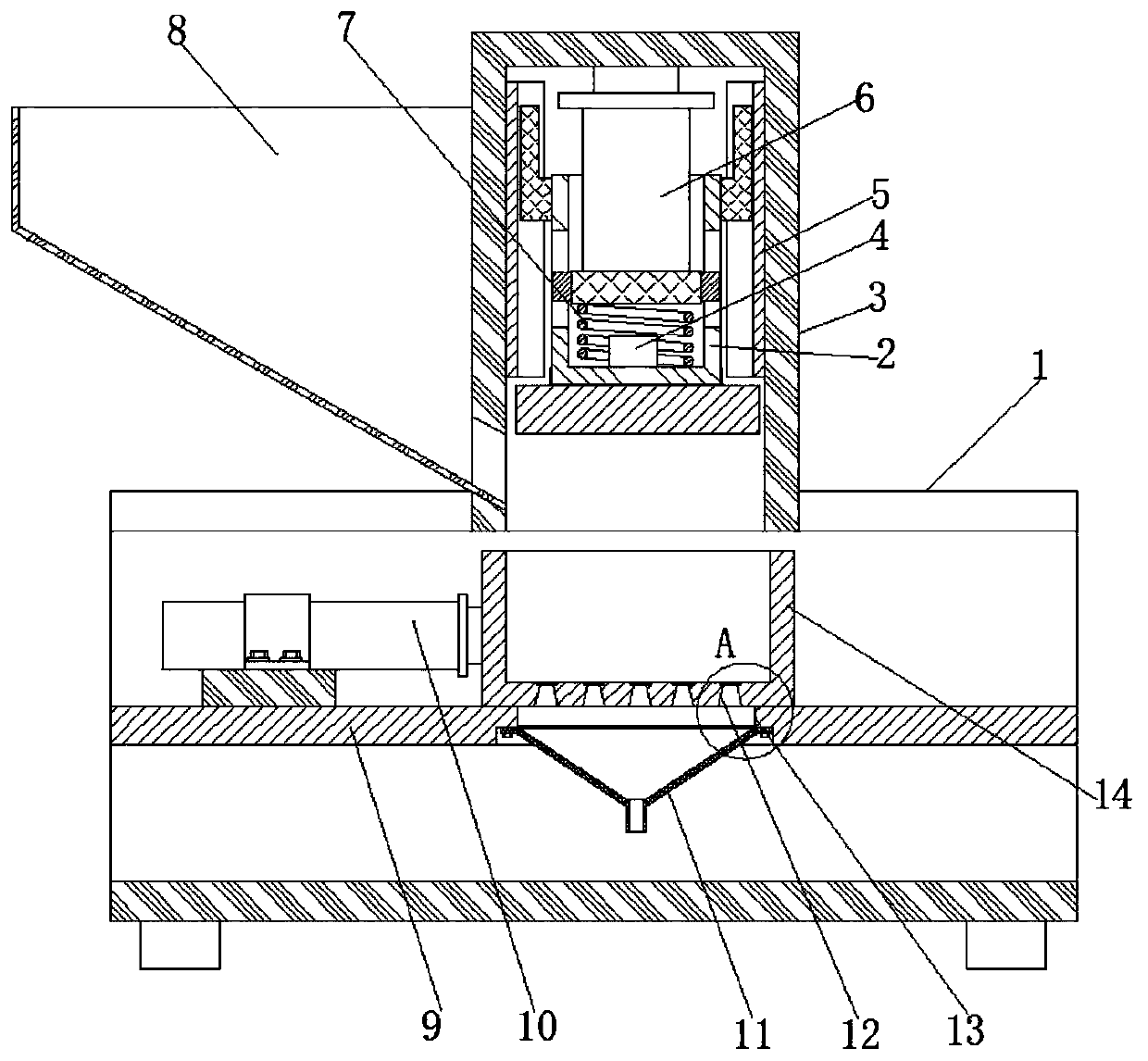

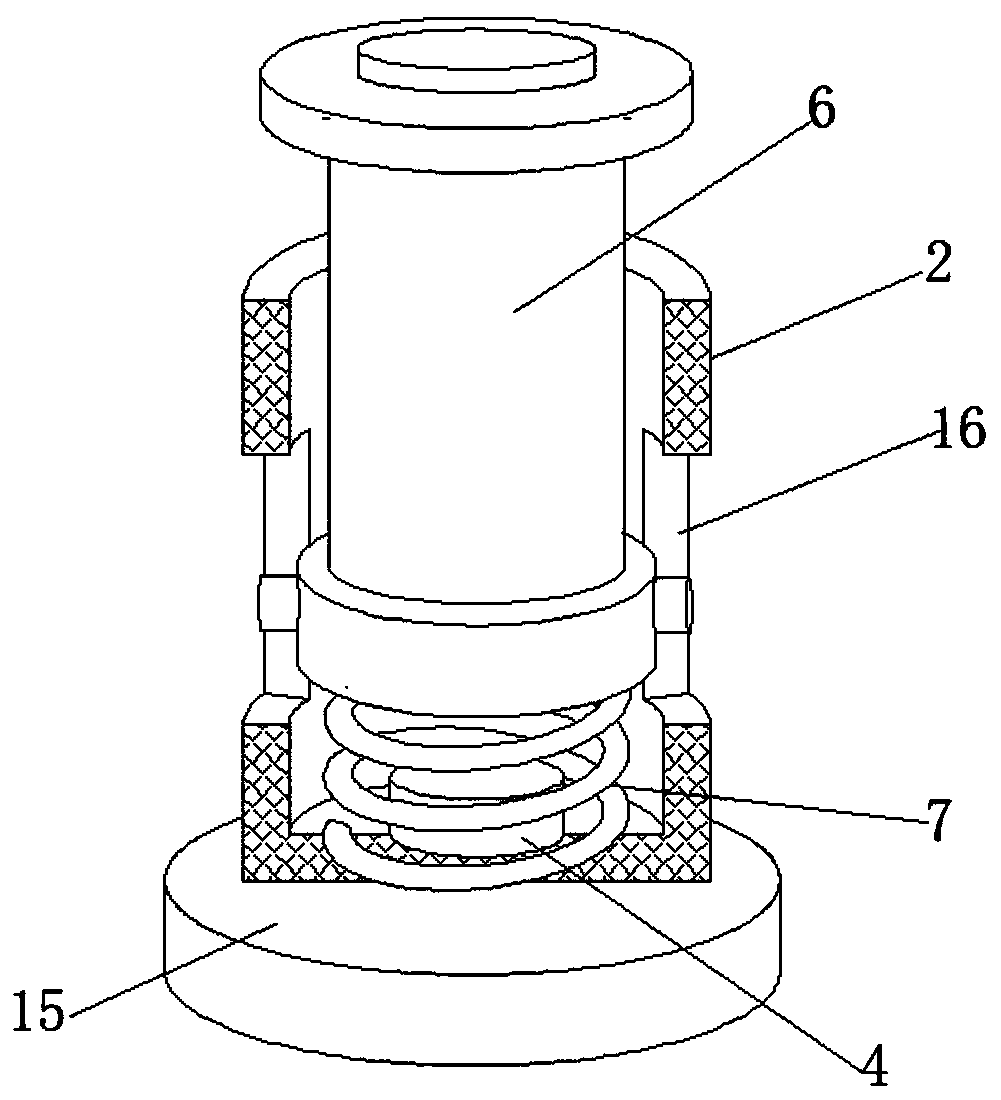

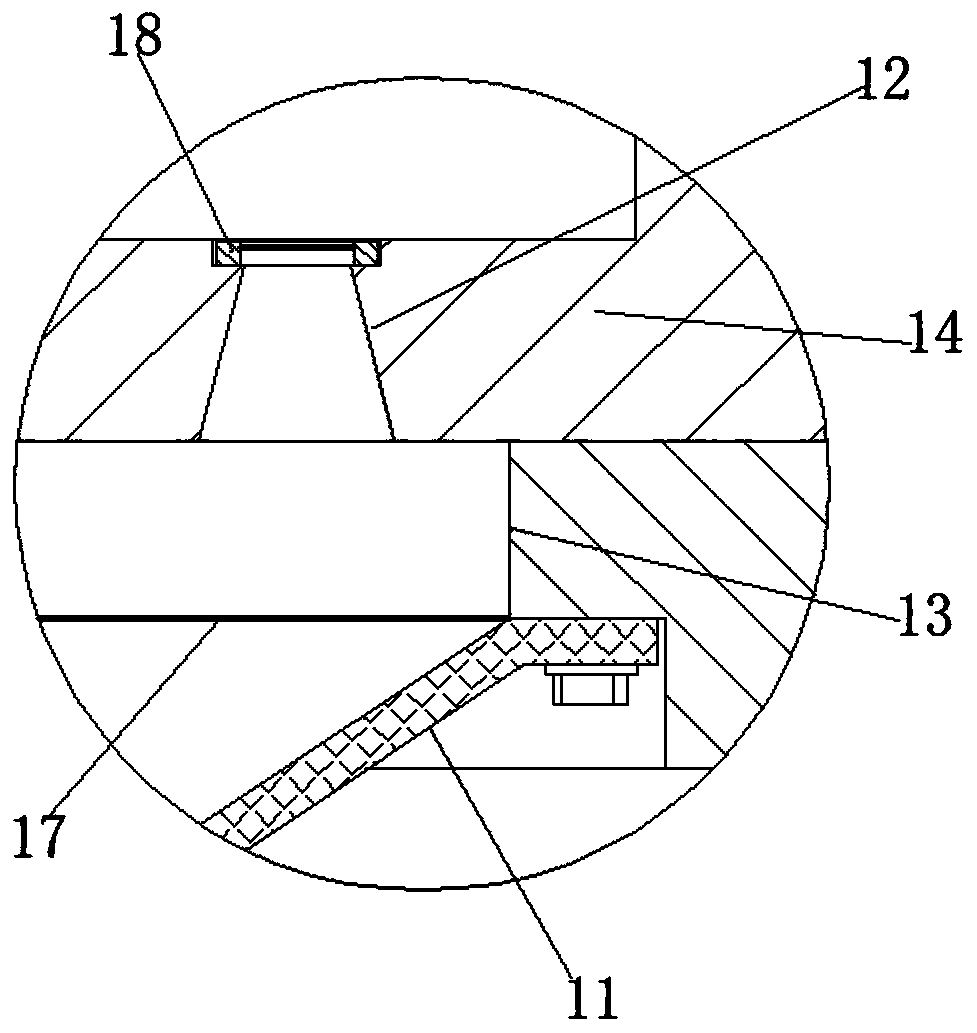

[0025] refer to Figure 1-3 , an iron chip recovery device for auto parts processing, comprising a base 1 with an upward opening in a C-shaped steel structure, a fixed box 3 with an opening downwards in a rectangular parallelepiped barrel-shaped structure snapped into the middle of the top of the base 1, and the top of the fixed box 3 The inner wall is provided with a hydraulic ejector rod 6, and the bottom of the main pipe of the hydraulic ejector rod 6 is fixed with a compression spring 7. plate 15, and the side of the fixed box 3 is provided with a feed port, the side of the feed port is provided with a material frame 8, the middle of the base 1 is provided with a partition 9, and the middle of the lower surface of the partition 9 has a ladder installation hole 13. A waste collection frame 14 is fixed on the upper surface of the partition 9 close to the top of the step installation hole 13, and the bottom of the waste collection frame 14 is provided with leaking holes 12 di...

Embodiment 2

[0032] refer to figure 1 and image 3 , an iron chip recovery device for processing auto parts. Compared with Embodiment 1, this embodiment also includes the hole diameters at the upper and lower ends of the leakage hole 12 at the bottom of the waste collection frame 14. The aperture is smaller than the aperture near the bottom, and the top of the leakage hole 12 is clamped with a filter ring 18 .

[0033] Working principle: When in use, the cutting fluid mixed in the waste chips can be quickly discharged when compressed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com