Flatting mill for waste ring-pull cans

A technology of cans and flattening machines, which is applied to presses, manufacturing tools, etc., and can solve problems such as inconvenient recycling, large volume of cans, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

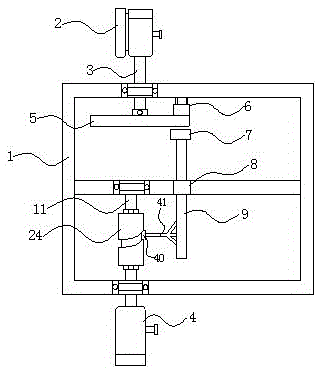

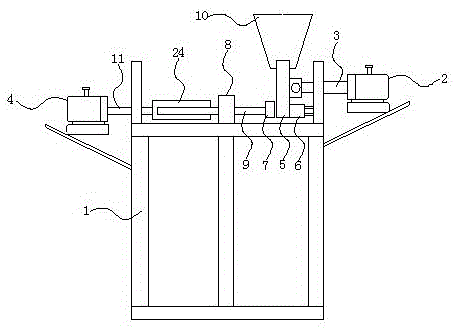

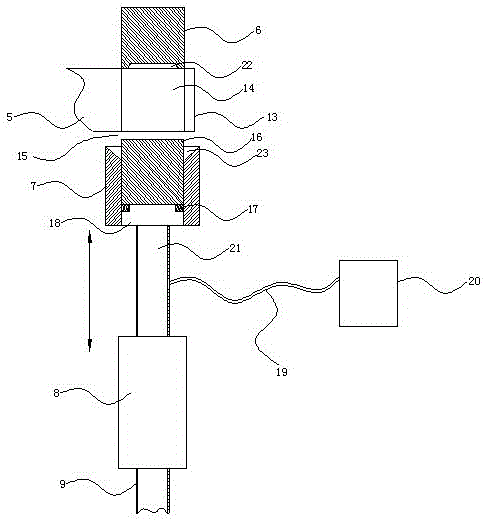

[0024] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0025] like Figure 1-7 As shown, it is a waste can crushing machine of the present invention, which includes a support frame 1, a crushing assembly, a fixed block 6 fixedly installed on the support frame 1, and a first rotating shaft 3 rotatably installed on the support frame 1 and the second rotating shaft 11, the first motor 2 for driving the first rotating shaft 3 to rotate, the second motor 4 for driving the second rotating shaft 11 to rotate, the rotating disc 5 installed on the first rotating shaft 3, and the The cylindrical cam 24 on the second rotating shaft 11, the feeding hopper 10 installed on the top of the rotating disk 5, the feeding device used to transport the waste pop cans 12 to the feeding hopper 10, the edge of the rotating disk 5 is provided with a In the material tank 14 for accommodating waste pop cans 12;

[0026] The crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com