Steel pipe cutting and flattening device

A technology for flattening devices and steel pipes, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as difficult transformation and no solution, achieve good effect, increase friction, and increase contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

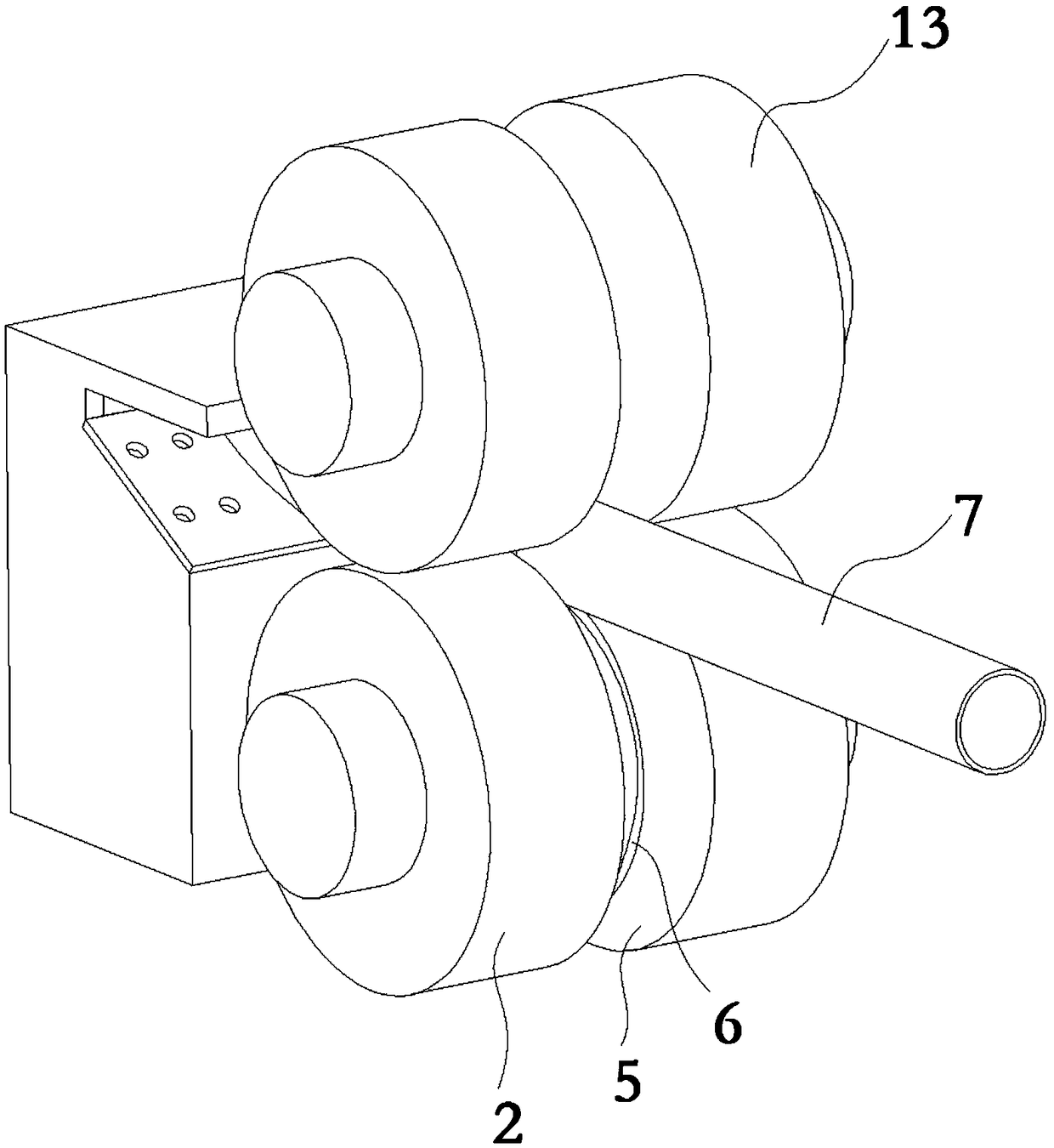

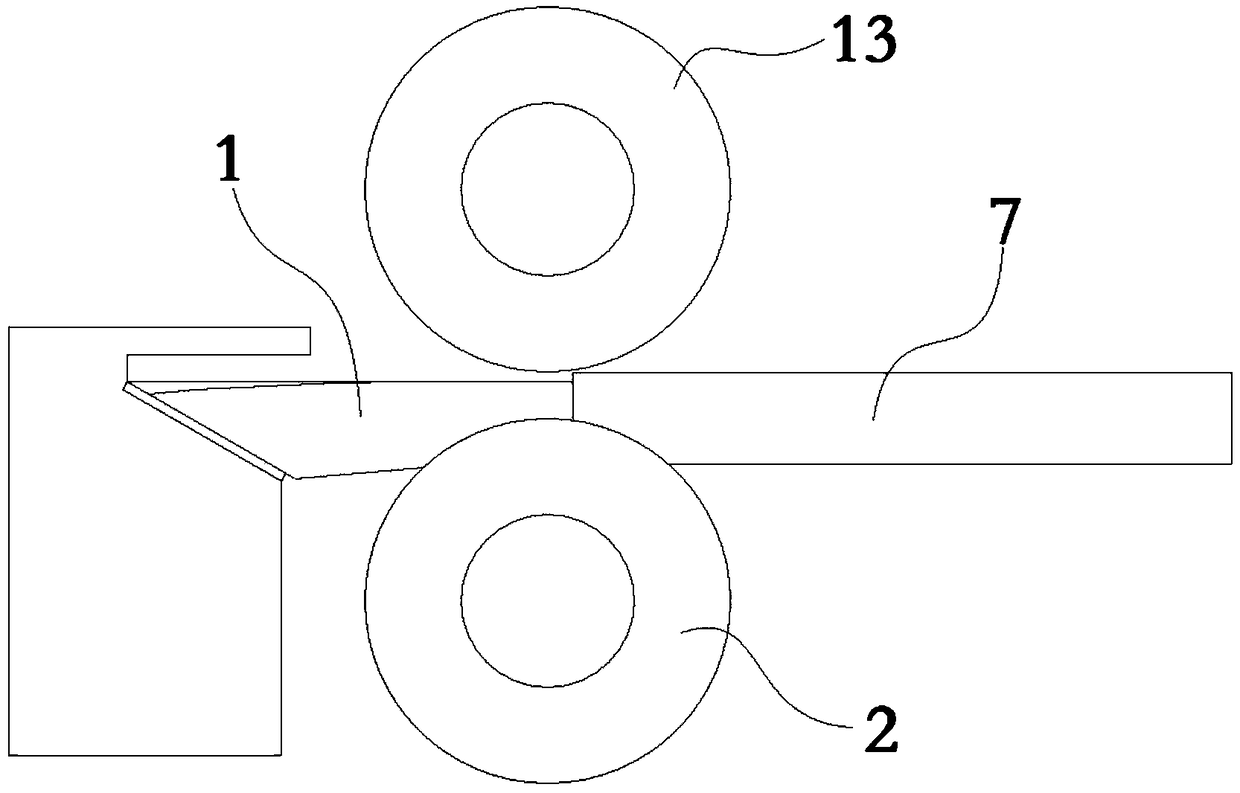

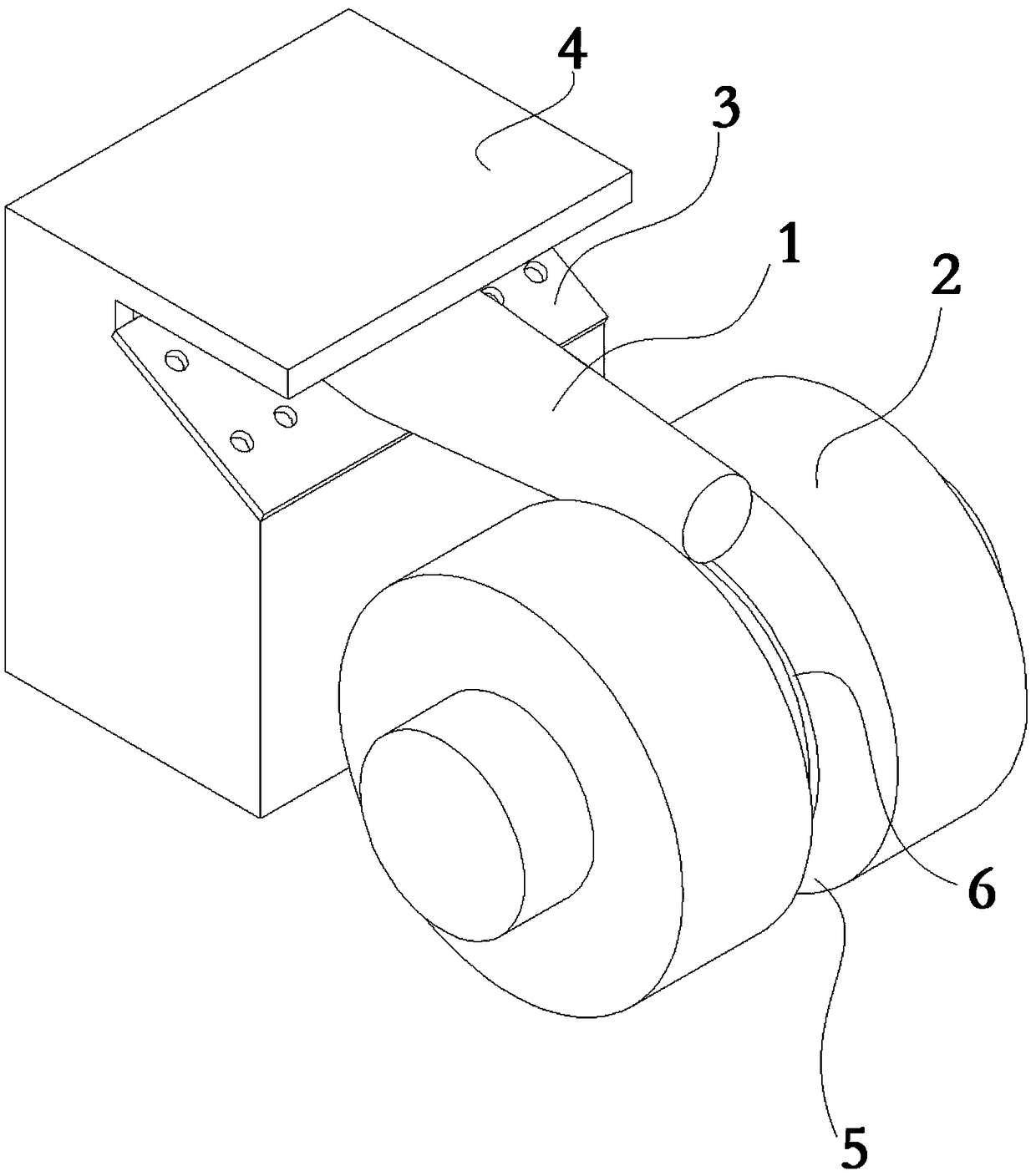

[0029] Such as Figure 1-Figure 6 As shown, the embodiment of the present invention includes an unfolding shaft 1, a transmission mechanism and a cutting mechanism;

[0030] The unfolding shaft 1 includes a suspended end 11 for covering the steel pipe 7 and a fixed end 10 connected to the frame 9. In this embodiment, the unfolding shaft 1 is arranged horizontally, the left end is the fixed end 10, and the right end is the suspended end 11. The shaft diameter of 1 gradually increases from the suspended end 11 to the fixed end 10. When the cut steel pipe 7 moves to the fixed end 10, the change of the shaft diameter will gradually expand the steel pipe 7;

[0031] The transmission mechanism is used to transport the steel pipe 7 from the suspended end 11 to the fixed end 10. The transmission mechanism includes a set of rollers driven by a motor, and the set of rollers includes a set of rollers arranged on the upper and lower sides of the unfolding shaft. The upper roller 13 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com