Part flattening system and method

A technology for parts and feature files, applied in the field of part flattening systems, can solve problems such as reduced design efficiency, unrealizable sheet metal design, and inability to flatten sheet metal parts, and achieves the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

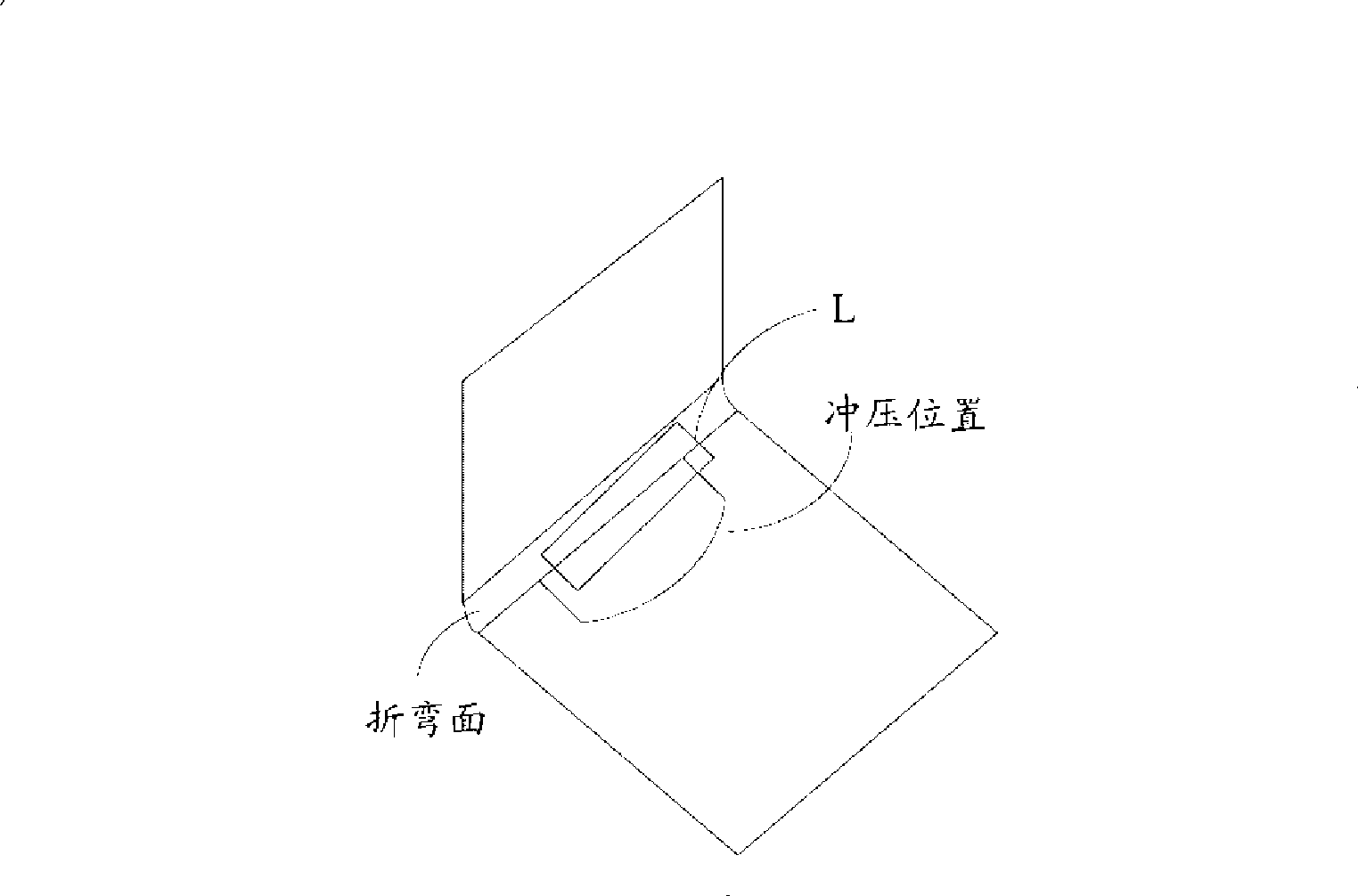

[0010] The part described in the part flattening system and method of the present invention refers to a part that satisfies the following characteristics: the stamping position of the part intersects the bending surface of the part.

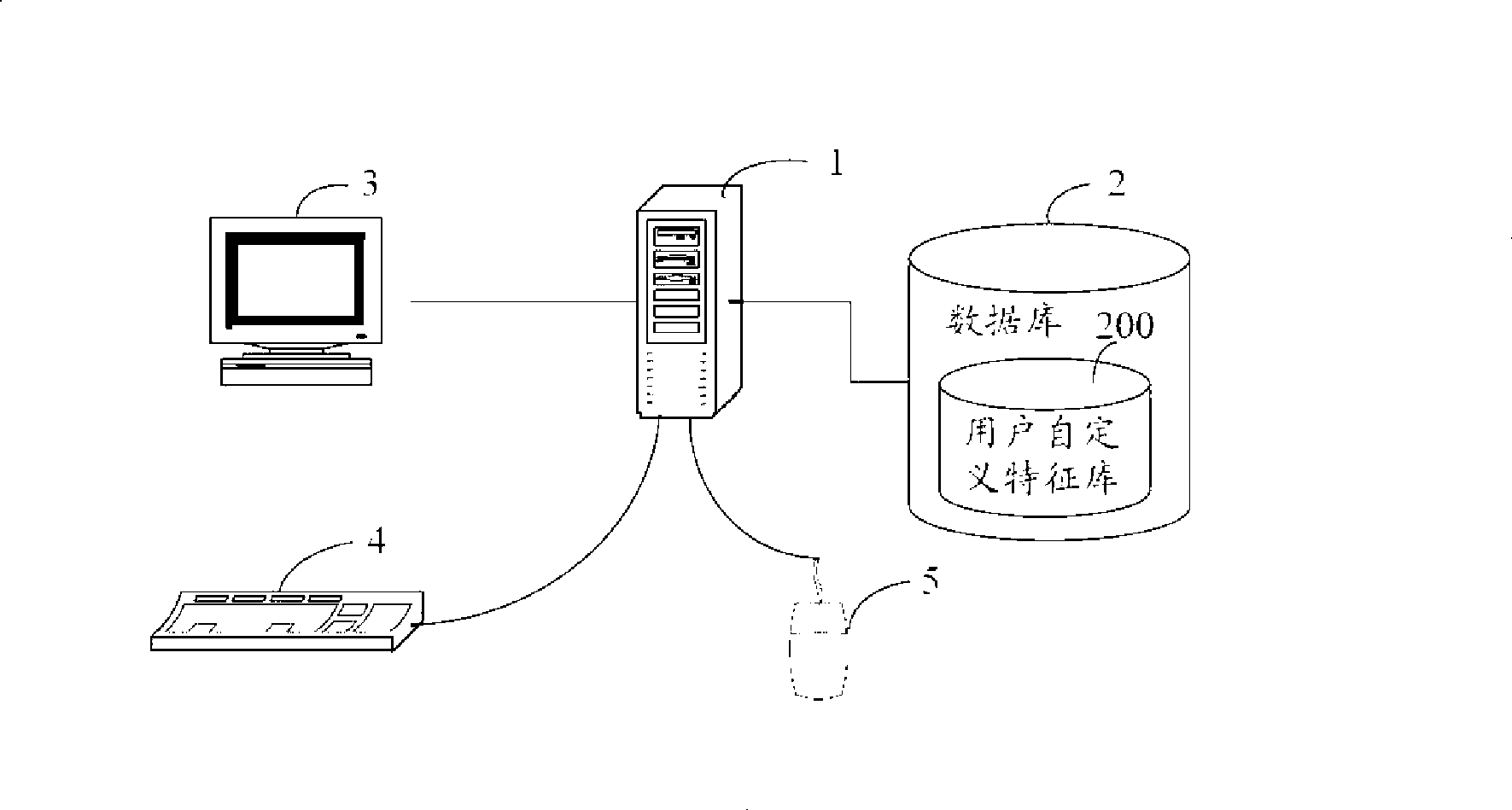

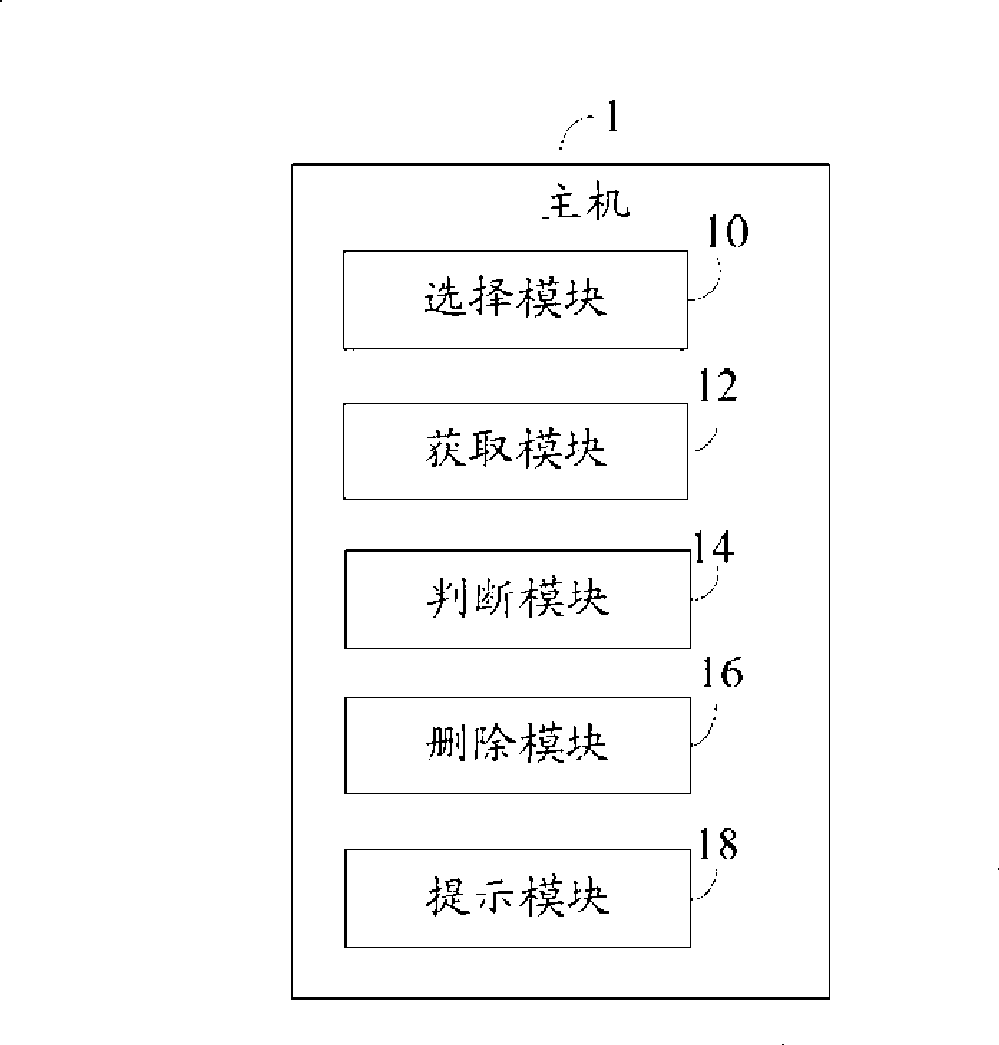

[0011] Such as figure 1 Shown is a hardware architecture diagram of a preferred embodiment of the parts flattening system of the present invention. The system includes a host 1 and a database 2 connected to it. Among them, host machine 1 is used to cut parts and flatten them. This database 2 is used for storing the sketch characteristic curve, and described sketch characteristic curve is closed, and this sketch characteristic curve comprises the sketch characteristic curve on XY plane, XZ plane, YZ plane, and this sketch characteristic curve is located The orientation of the plane is fixed. The database 2 also includes a user-defined feature (User Defined Feature, UDF) library 200, the user-defined feature library 200 stores different feature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com