Leveling machine for paper bag production

A technology of flattening machine and paper bag, applied in the field of flattening machine, to achieve the effect of high flattening efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

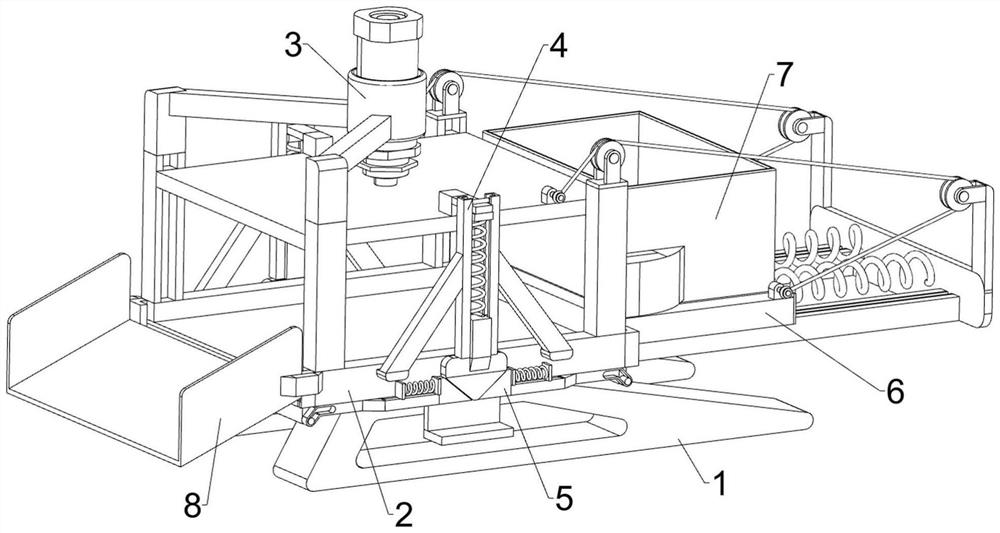

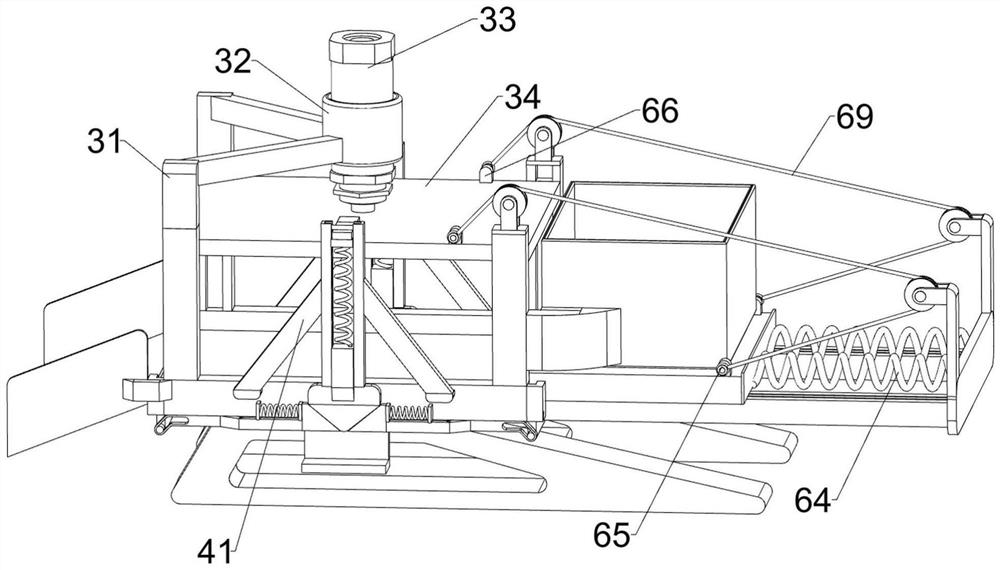

[0021] Such as figure 1 , figure 2 and Figure 4 As shown, a flattening machine for paper bag production includes a base 1, a mounting frame 2, a flattening mechanism 3, a linkage mechanism 4 and a baffle mechanism 5, the top of the base 1 is connected with a mounting frame 2, and the mounting frame 2 is respectively A flattening mechanism 3 , a linkage mechanism 4 and a baffle mechanism 5 are installed, the linkage mechanism 4 is connected in transmission with the flattening mechanism 3 , and the baffle mechanism 5 is connected in transmission with the linkage mechanism 4 .

[0022] The flattening mechanism 3 includes a first rail frame 31, a fixed frame 32, a cylinder 33 and a pressing plate 34. The four corners on the top of the mounting frame 2 are connected with the first rail frame 31, and the two first rail frames 31 on the left side A fixed frame 32 is connected between the side upper parts, and a cylinder 33 is installed in the fixed frame 32, and a pressing plate ...

Embodiment 2

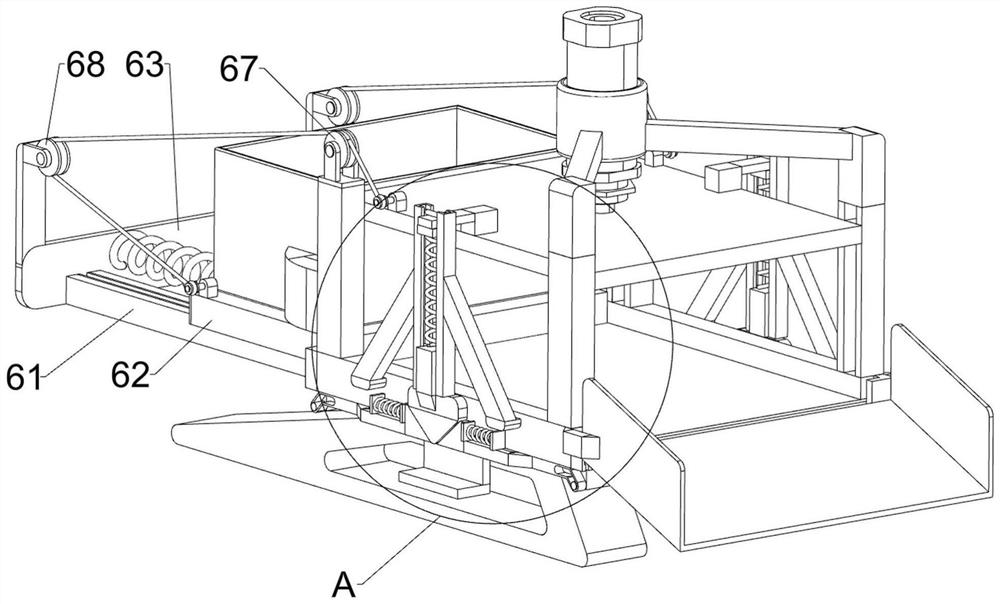

[0027] On the basis of Example 1, such as Figure 1-Figure 3 As shown, a material storage box 7 and a guide frame 8 are also included, the material storage box 7 is connected between the right sides of the two first guide rail frames 31 on the right side, and the guide frame 8 is connected to the left side of the installation frame 2 .

[0028] Also include pusher mechanism 6, pusher mechanism 6 includes the 3rd guide rail frame 61, sliding push plate 62, fixed baffle plate 63, the 3rd back-moving spring 64, the first connection seat 65, the second connection seat 66, the first Fixed pulley 67, the second fixed pulley 68 and steel cable 69, the front and back symmetrically connected with the third guide rail frame 61 on the right side of the mounting frame 2, sliding push plate 62 is connected in sliding type between the tops of the two third rail frames 61, A fixed baffle 63 is connected between the right sides of the two third guide rail frames 61, and a third return spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com