Femtosecond laser direct writing sapphire ring light guide and preparation method thereof

A femtosecond laser and sapphire technology, applied in the field of optoelectronics, can solve the problems of narrow transmission spectrum, poor mechanical strength and complexity, and achieve the effects of easy optical system integration, high temperature resistance transmission spectrum, and overcoming complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

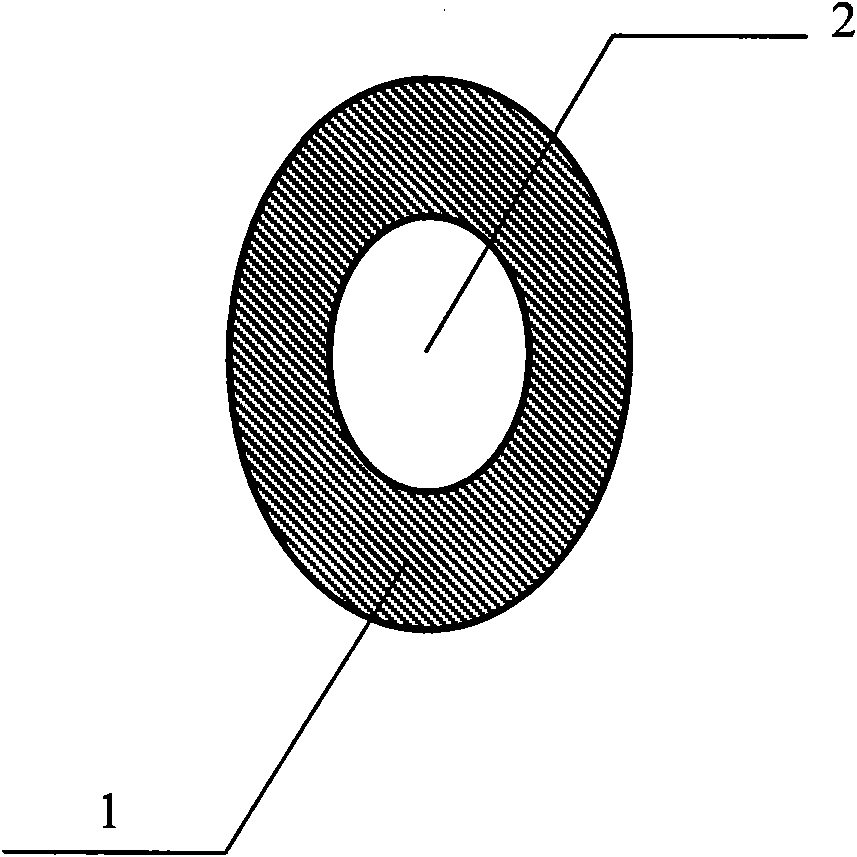

[0038] Refer to attached figure 1 , The femtosecond laser direct writing sapphire ring light guide area 1 of the present invention is a three-dimensional ring within 200nm adjacent to the femtosecond laser active area 2, and the cross section of the waveguide of the present invention is ellipsoidal.

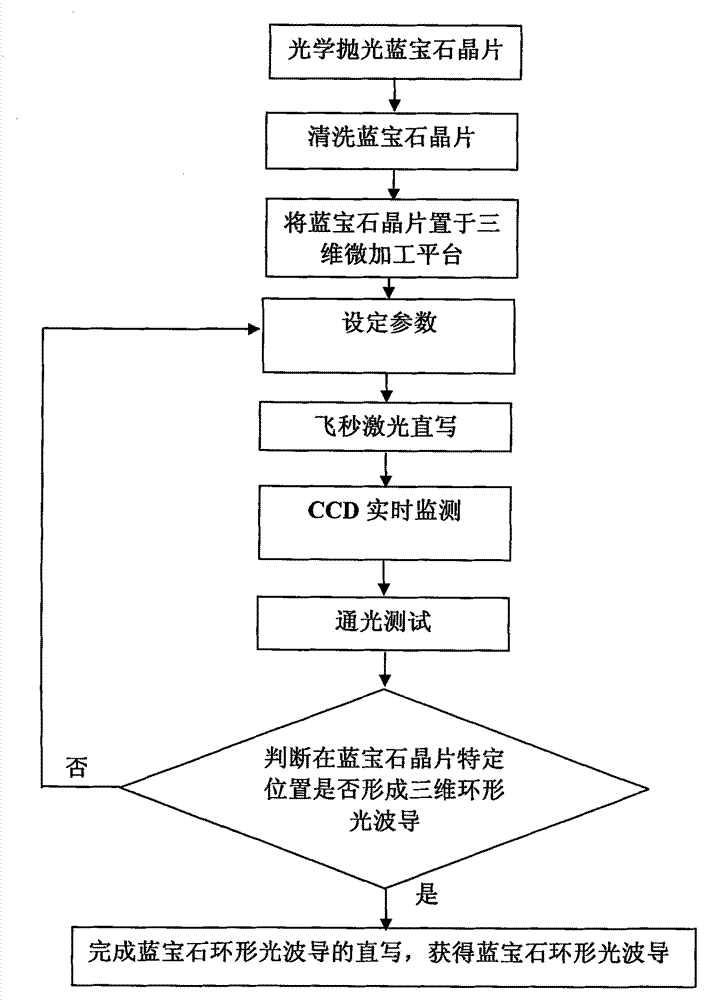

[0039] Refer to attached figure 2 , to further describe the implementation method of the present invention.

[0040] Step 1, optically polish the sapphire wafer.

[0041] Optically polishing square or round sapphire wafers with a thickness of 1-2 mm and a purity >96% to obtain a sapphire wafer with a flatness of <10 μm, a polished surface roughness of Ra <0.3 nm and a curvature of <10 μm. In the embodiment of the present invention, a square sapphire wafer with a thickness of 1mm and a purity of 99.9% is used. The polished flatness is 7 μm, the roughness is 0.2 nm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com