Preparation method for high-purity and high-density WS2 lamellar nano structure

A nanostructured and lamellar technology is applied in the field of preparation of high-purity, high-density WS2 lamellar nanostructures, achieving the effects of controllable diameter and thickness, strictly controllable synthesis and growth conditions, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention proposes a high-purity, high-density WS 2 The preparation method of lamellar nanostructure is characterized in that the method synthesizes high-density WS on a substrate coated with a tungsten film by thermally evaporating tungsten oxide and sulfur 2 Lamellar nanostructure, and comprising the following steps and content:

[0024] (1) The evaporation source used is commercially available analytically pure WO 3 powder and sulfur powder.

[0025] (2) Deposit a layer of metal with a thickness of 5-100 nm on a clean silicon wafer, gallium arsenide wafer, silicon carbide single wafer or aluminum oxide single wafer by magnetron sputtering coater or arc evaporation in advance. W film.

[0026] (3) In the vacuum tube furnace, there will be respectively equipped with WO 3 Alumina ceramic crucibles of powder and S powder, or filled with WO 3 The alumina ceramic crucible mixed with S powder is placed in the heating area in the center of the furnace, and t...

Embodiment 1

[0035] Embodiment 1: will house 0.5 g analytically pure WO 3 The powdered alumina ceramic crucible is placed in the central heating zone of the vacuum tube furnace, and a WO 3 An alumina ceramic crucible containing 1 g of analytically pure S powder was placed at a distance of 8 mm from the crucible of the powder, and a WO 3 A silicon wafer coated with a W film with a thickness of 40 nm was placed at 14 mm from the powder crucible.

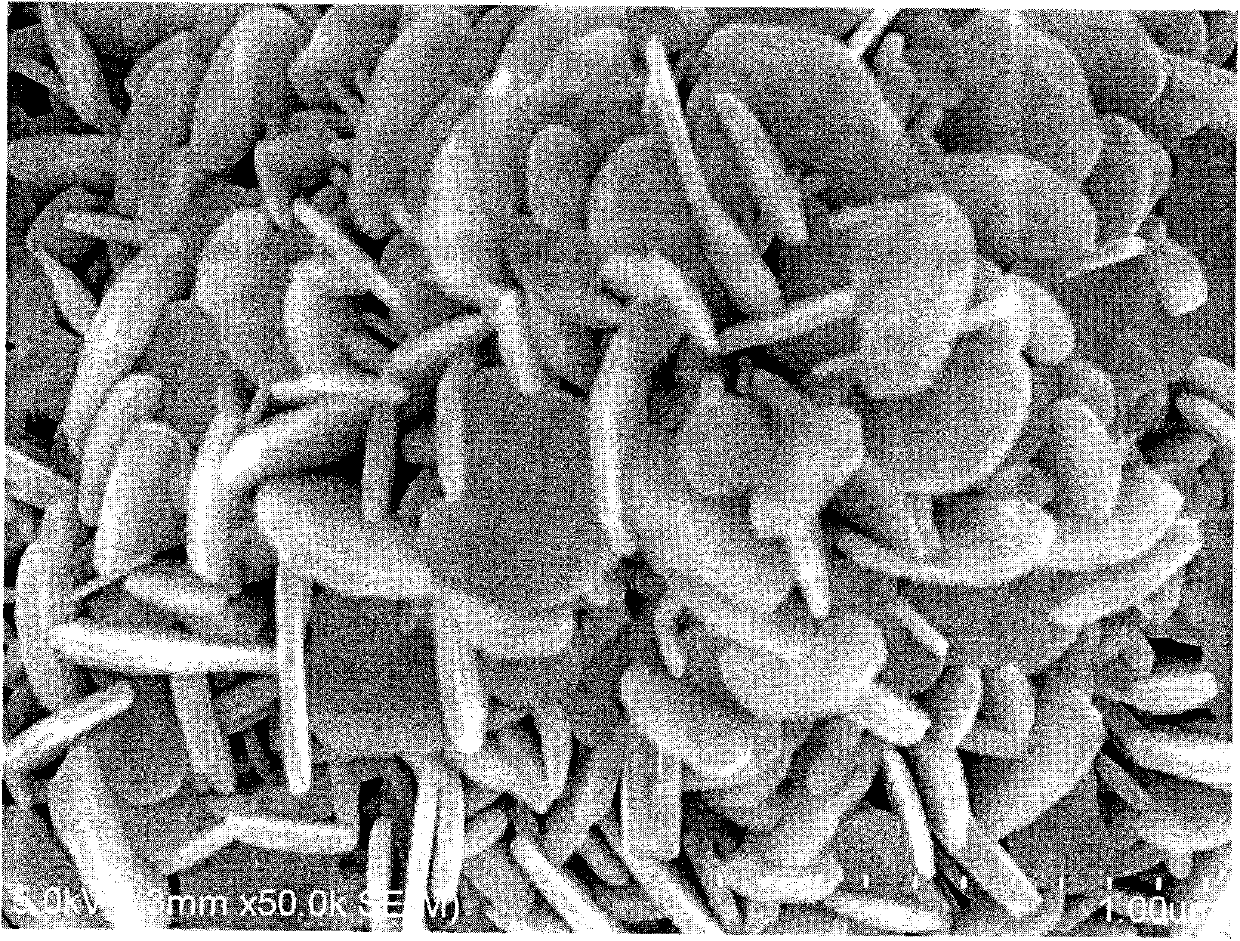

[0036] Before heating, the whole system was evacuated first, and then 99.99 vol.% argon gas was introduced into the system, and repeated 2 times to remove the air in the system. Then the temperature was raised to 1050 °C at a rate of 30 °C / min and kept for 2 h. During the heating process, keep the flow rate of the carrier gas at 200 sccm, and finally cool down to room temperature naturally to obtain high-density WS on the substrate. 2 Lamellar nanostructures.

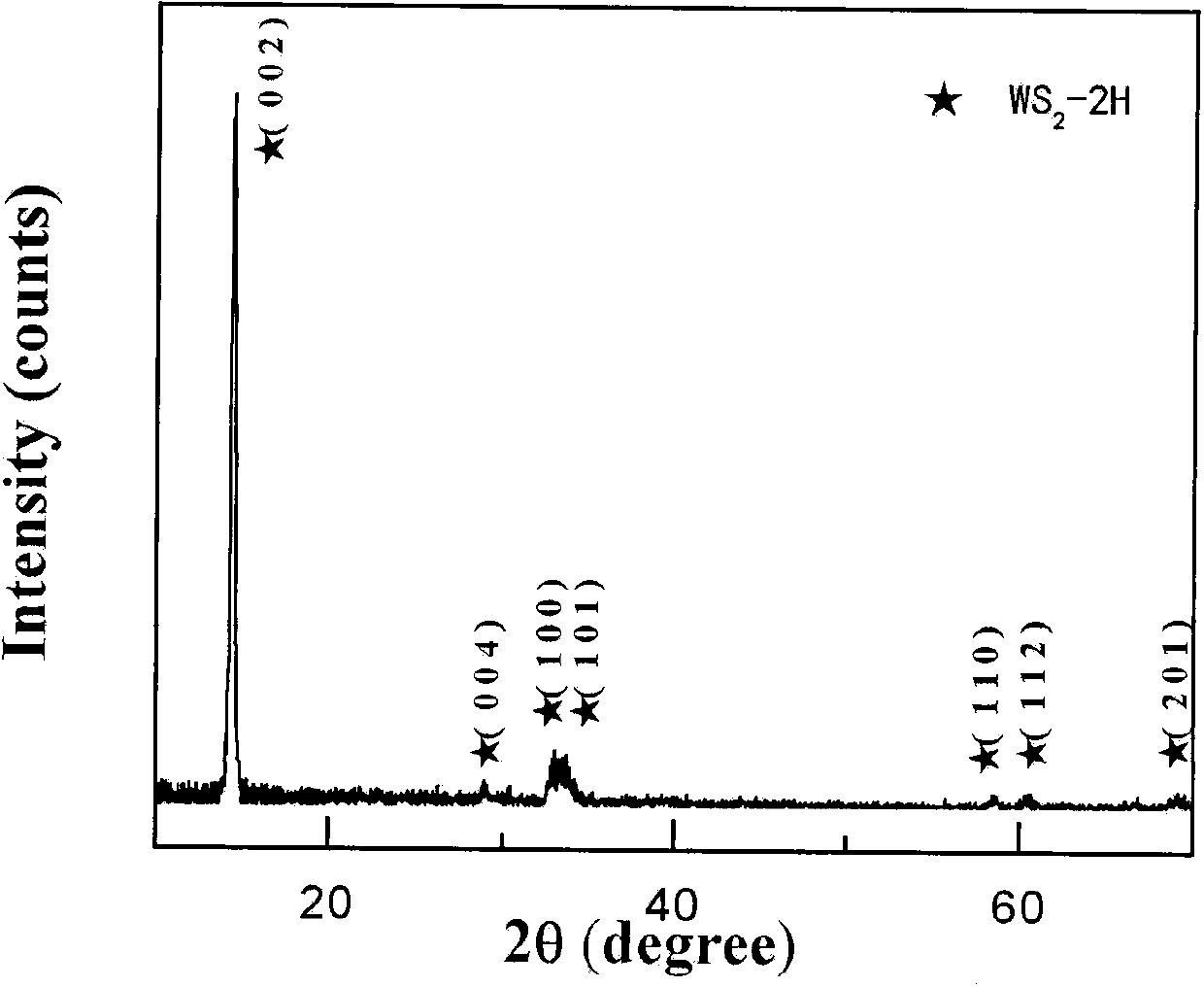

[0037] The synthesized sample is WS 2 Single crystal, no impurity phase (see figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com