Sapphire wafer grinding and polishing method

A sapphire wafer, rough grinding technology, applied in the direction of grinding/polishing equipment, grinding machine tools, grinding devices, etc., can solve the problems affecting the difficulty of processing and achieve the effect of low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

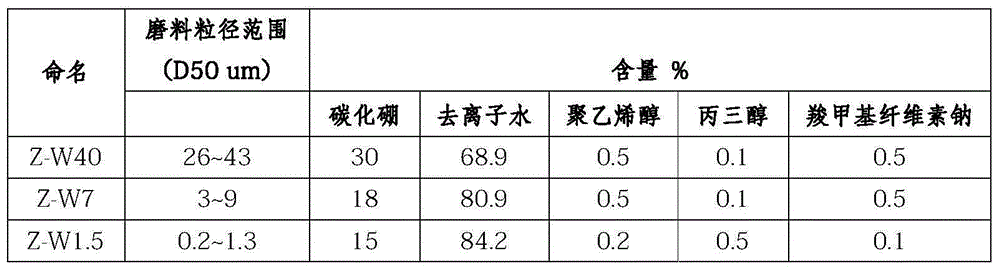

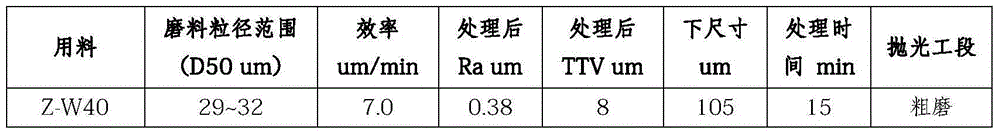

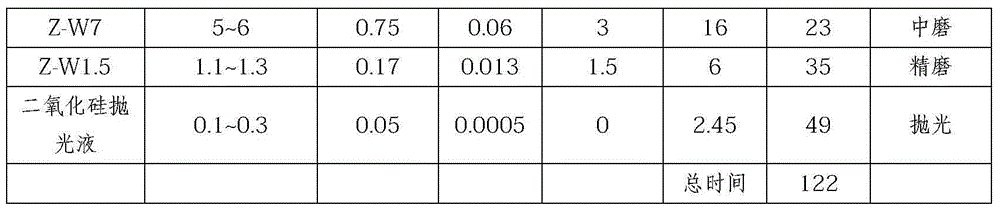

Embodiment 1

[0029] The sapphire polishing wafer polishing method provided by the present invention specifically includes four processes, namely rough grinding, intermediate grinding, fine grinding and polishing. In this embodiment, the high-hardness micropowder used in coarse grinding, medium grinding and fine grinding is boron carbide, and the particle size of boron carbide is preferably W40, W7 and W1.5 standard micropowder respectively. In the process of actual use, high hardness micropowder can also be Choose silicon carbide or diamond. In this embodiment, glycerol is selected as the suspending agent, and sodium hydroxymethylcellulose is selected as the dispersing agent. Of course, the suspending agent can also choose one or more of polyacrylamide, polyacrylic acid, sodium polyacrylate or ethylene glycol according to needs; the dispersing agent can also choose sodium carboxymethylcellulose, sodium hydroxymethylcellulose, hydroxyl One or more of ethyl cellulose sodium, sodium alginate...

Embodiment 2

[0041] The present invention also provides another specific embodiment for detailed description. The program specifically includes four processes, namely rough grinding, medium grinding, fine grinding and polishing. In this embodiment, the particle diameters of the boron carbide micropowders used in coarse grinding, medium grinding and fine grinding are preferably W40, W7 and W3.5 standard micropowders respectively. The grinding liquid is configured according to the formula listed in Table 4 and named Z-W40, Z-W7 and Z-W3.5 respectively. The silicon dioxide polishing liquid adopts a typical commercial polishing liquid. The special chemical polishing fluid of Zhongwei Lihe is preferred.

[0042]Table 5 lists another embodiment of the present invention, from grinding to polishing, and it takes 2.9 hours to complete. The common sapphire polishing scheme listed in Table 6 takes 5 hours from grinding to polishing. In the commonly used plan in Table 6, the first process of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com