Sapphire wafer cutting method

A sapphire wafer and cutting wire technology, which is applied in chemical instruments and methods, stone processing equipment, fine working devices, etc., can solve the problems of high cost, large material loss, and high price of diamond abrasive wires, and achieve improved dispersion and stability The effect of high capacity, small equipment investment and low cutting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Equipment used: MWS-3020 crystal multi-wire cutting machine. The main process settings are as follows:

[0015] Cutting speed: max 300~400m / min. Running speed change: acceleration and deceleration time 1s / constant speed time 6~10s. Line speed setting: 15~35m / min. Thread cutting tension setting: 28-31N on the supply side and 28-31N on the recovery side. Cutting speed: 2.0~6.0mm / h.

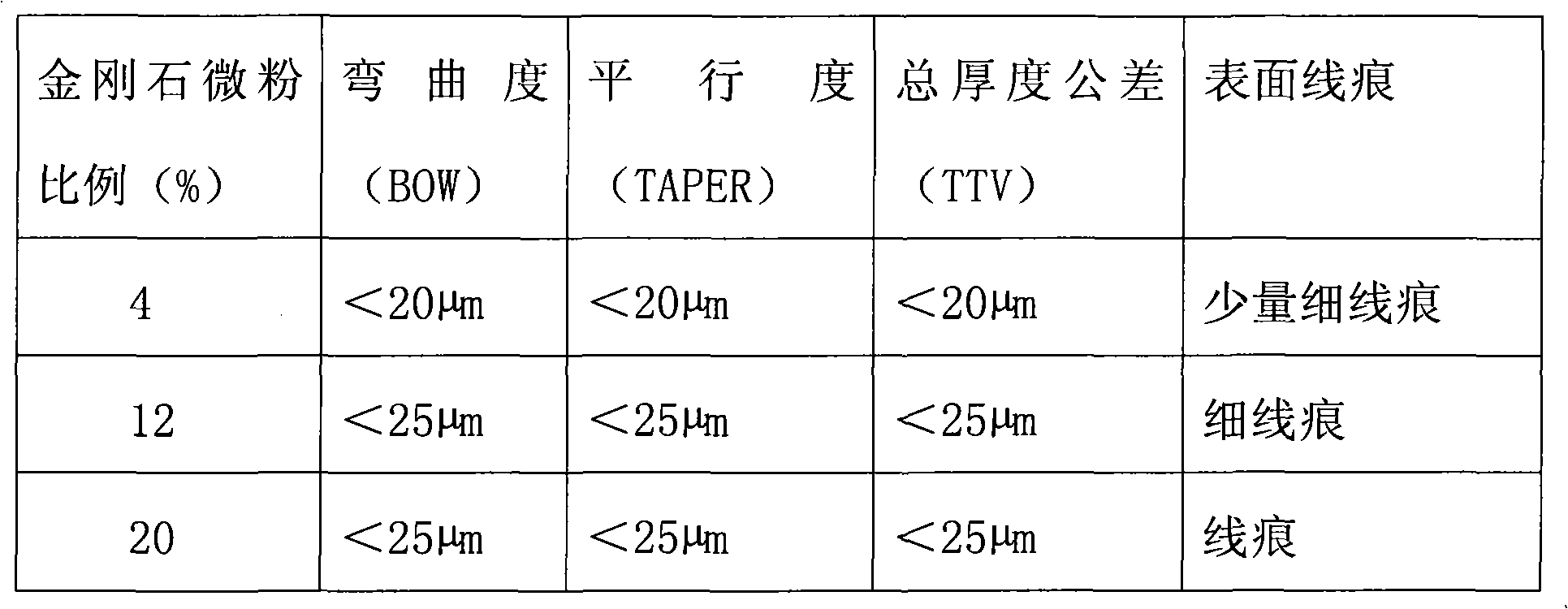

[0016] The cutting oil is PS-L-25 cutting oil produced by Japan PALACS, with a viscosity of 30mp at 25°C a .s. The abrasive material is diamond micropowder with a particle size of 4-12 μm. The diamond micropowder is formulated into a mortar cutting fluid with cutting oil in three proportions of 4%, 12%, and 20% by weight. The main technical indicators of the cut wafers are as follows:

[0017]

[0018] All indicators meet the requirements of LED substrates.

Embodiment 2

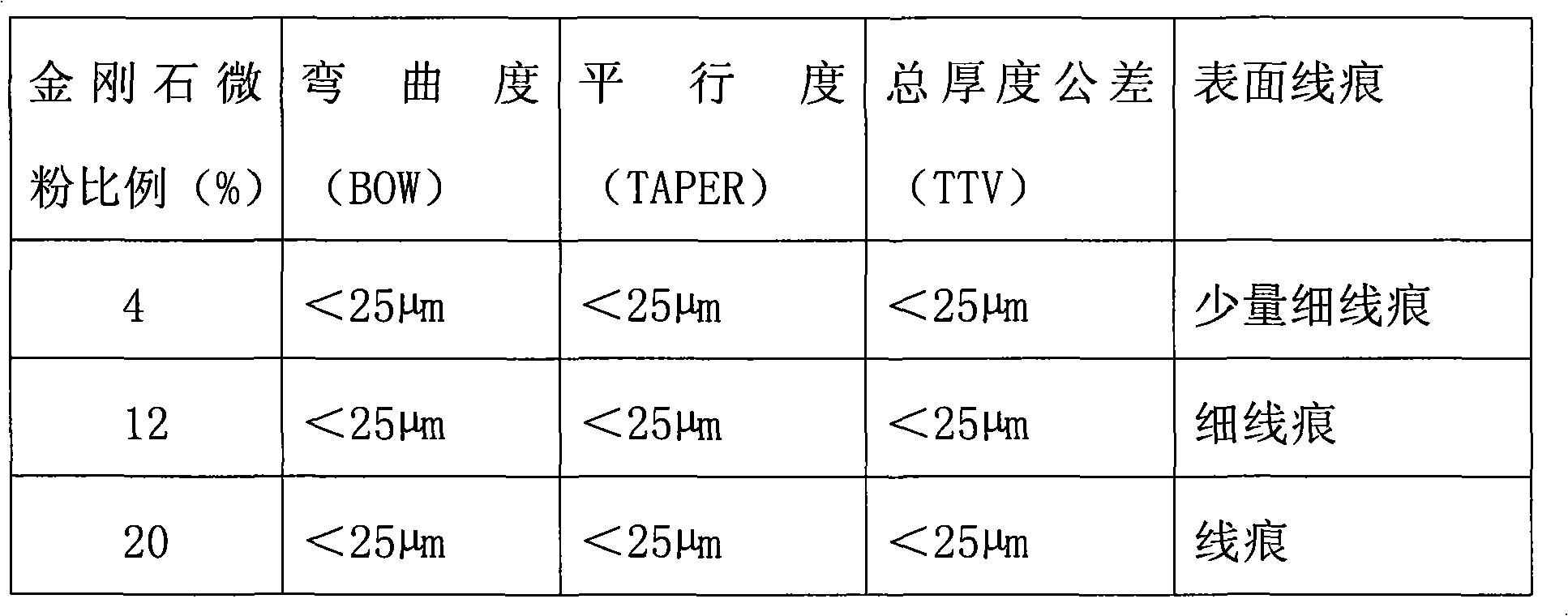

[0020] The equipment and process parameters used are the same as above. The cutting oil is FB-10 cutting oil produced by Shenzhen Jinke Chemical Industry Co., Ltd., with a viscosity of 50mp at 25°C a .s. The abrasive material is diamond micropowder with a particle size of 4-12 μm. The diamond micropowder is formulated into a mortar cutting fluid with cutting oil in three proportions of 4%, 12%, and 20% by weight. The main technical indicators of the cut wafers are as follows:

[0021]

[0022] All indicators meet the requirements of LED substrates.

Embodiment 3

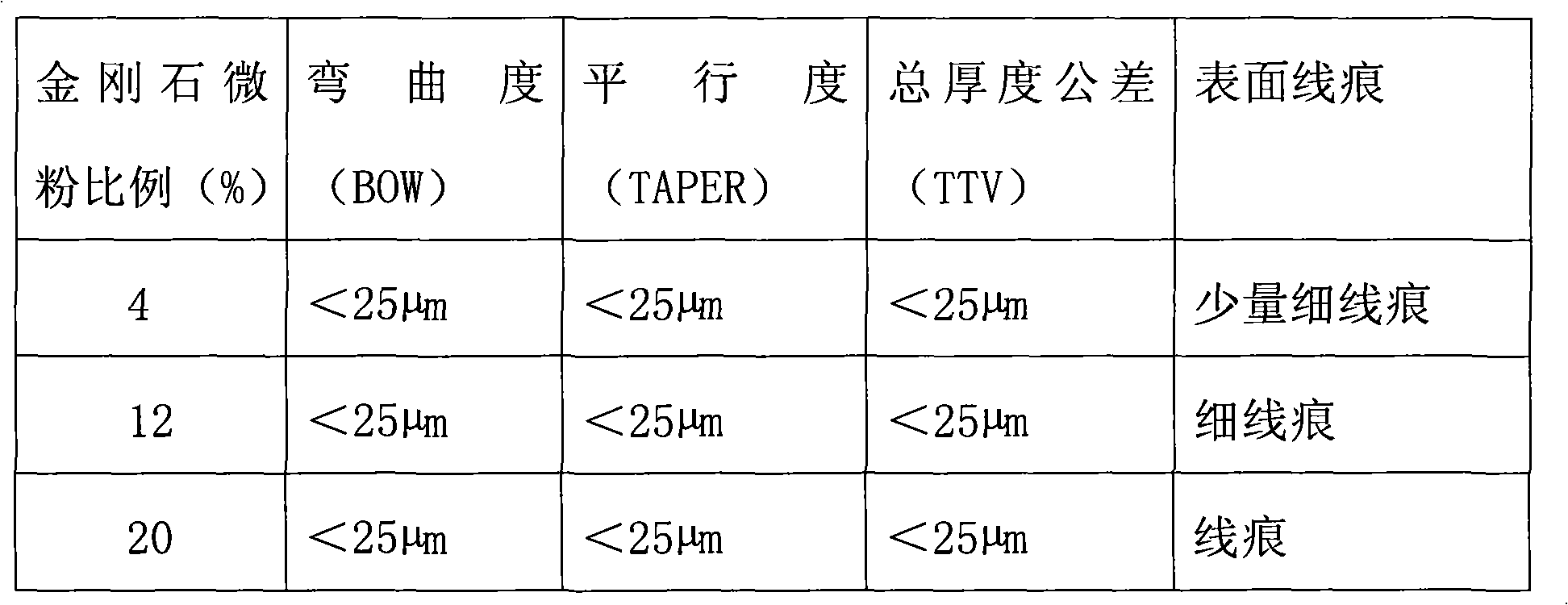

[0024] The equipment and process parameters used are the same as above. The cutting oil adopts Lianchuang brand crystal cutting oil with a viscosity of 20mp at 25°C a .s. The abrasive material is diamond micropowder with a particle size of 4-12 μm. The diamond micropowder is formulated into a mortar cutting fluid with cutting oil in three proportions of 4%, 12%, and 20% by weight. The main technical indicators of the cut wafers are as follows:

[0025]

[0026] All indicators meet the requirements of LED substrates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com