Polishing device and method of sapphire wafer

A technology for sapphire wafers and polishing devices, which is applied in the direction of grinding devices, grinding/polishing equipment, grinding machine tools, etc., can solve the problems of poor flatness of the wafer surface, unstable polishing removal rate, uneven polishing liquid, etc., and achieve Reduce uneven stirring, reduce scratches and scratches, good uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

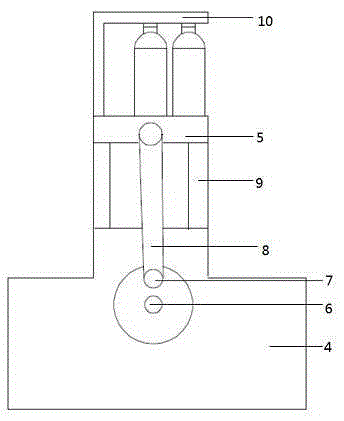

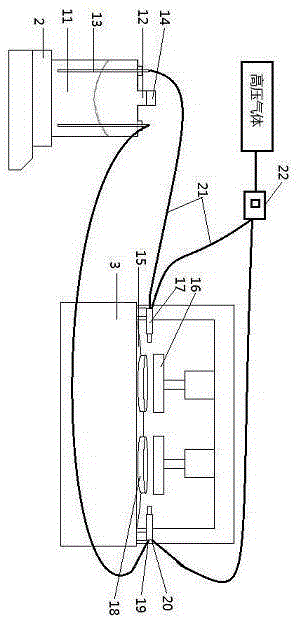

[0022] A polishing device for a sapphire wafer as shown in the figure is characterized in that it includes a vibrator 1, a heating magnetic stirrer 2 and a polishing machine 3, and the vibrator 1 includes a base 4, a throwing seat 5, a motor 6, an eccentric Wheel 7 and connecting rod 8, described base 4 is provided with 4 sliding shafts 9, and described sliding shaft 9 is the linear optical axis that vertically sets, and the both sides of described throwing seat 5 fits on sliding shaft 9 , the throwing seat 5 is provided with a fixed block 10, the motor 6 is arranged in the base 4, the eccentric wheel 7 is fixedly connected with the transmission end of the motor 6, and the upper end of the connecting rod 8 is connected to one of the throwing seat 5. The side is hinged, and the lower end is hinged with the eccentric wheel 7 to realize the vertical movement of the throwing seat 5;

[0023] The heating magnetic stirrer 2 includes a stirring container 11, the stirring container 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com