Sapphire wafer dividing method

A sapphire wafer and sapphire technology, applied in stone processing equipment, fine working devices, laser welding equipment, etc., can solve the problems of obstructing laser line irradiation, unable to form a modified layer, etc., and achieve the effect of improving the manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

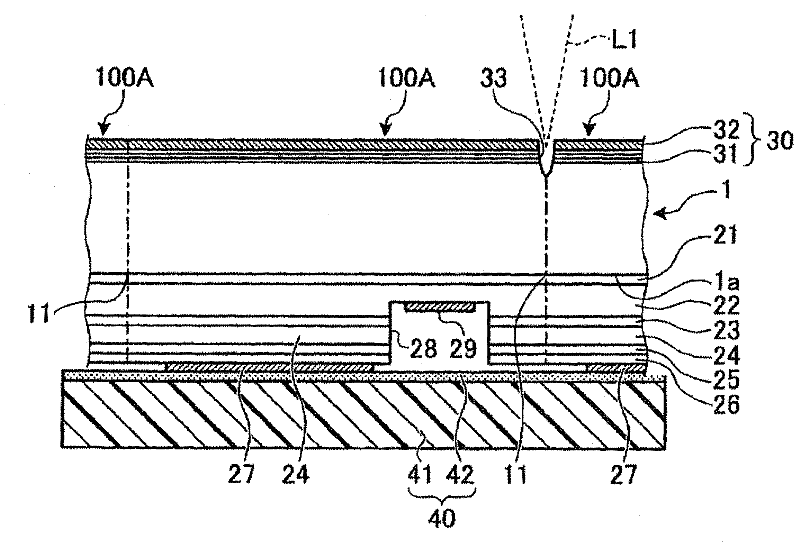

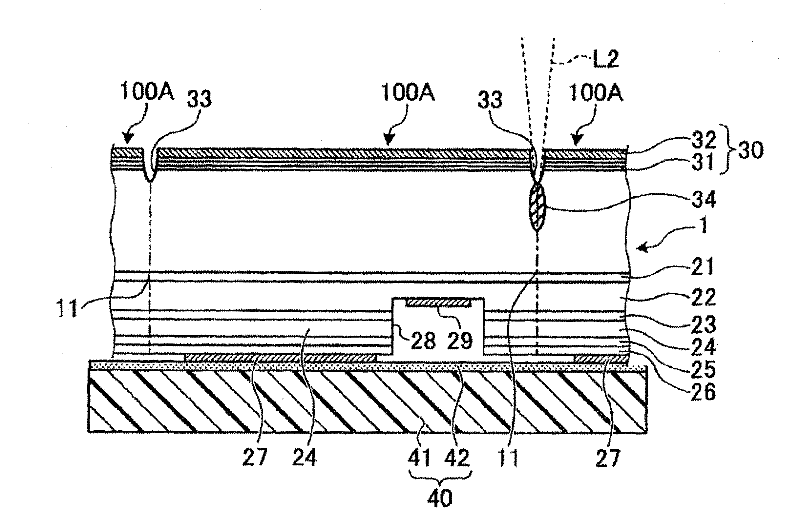

[0016] Hereinafter, a method for dividing a sapphire wafer according to an embodiment of the present invention will be described in detail with reference to the drawings. It should be noted that the drawings are only schematic illustrations, and the thickness and thickness ratio of each layer are different from actual ones. In addition, in the method of dividing a sapphire wafer according to the present embodiment, a wafer in which a semiconductor layer, a reflective film, and the like are formed on a sapphire wafer to form a light-emitting element as a light-emitting device is used as an object of division.

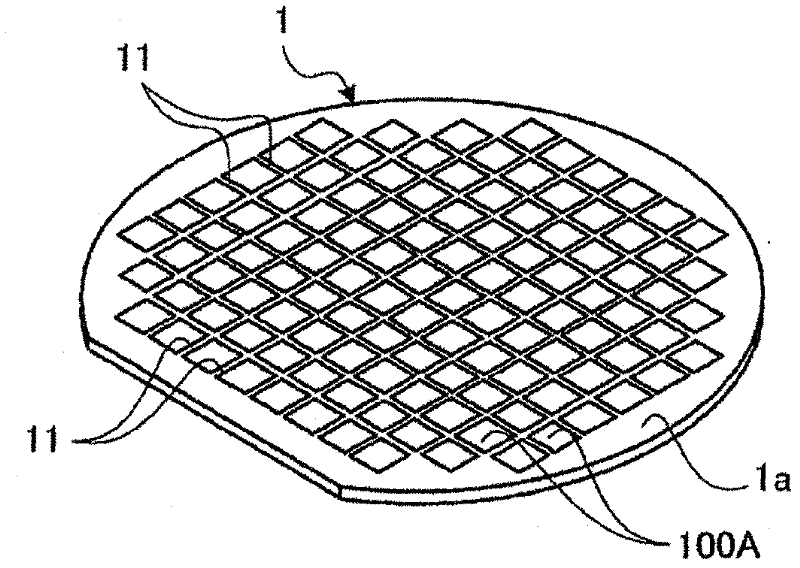

[0017] Here, as an example of a sapphire wafer to which the dividing method according to the embodiment of the present invention is applied, Figure 1 ~ Figure 3 A sapphire wafer 1 is shown for illustration. like figure 1 As shown, in this sapphire wafer 1 , light-emitting element portions 100A are formed in respective regions of the front surface 1 a of the sapphire w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com