Efficient C-oriented sapphire polishing solution and preparation method thereof

A polishing liquid and sapphire technology, applied in the field of polishing liquid, can solve the problems of affecting the surface quality and easy loss, and achieve the effect of improving the leveling efficiency, improving the efficiency and shortening the polishing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

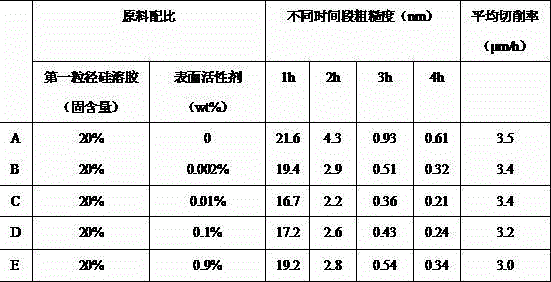

[0032] Prepare five polishing solutions A, B, C, D, E:

[0033] Weigh the first particle size silica sol, the second particle size silica sol, surfactant, complexing agent and water according to the weight ratio, add 0.1g N-acylamino acid salt to 590g, 490g, 565g, 540g, 515g water respectively Surfactant, after stirring, add 0g, 500g, 125g, 250g, 375g of the first particle size silica sol with a solid content of 40% and a particle size of 20nm, and then add 400g, 0g, 300g, 200g, 100g after stirring evenly The solid content is 50%, and the particle size is the second particle size silica sol of 90nm. After stirring evenly, 10g of amine trimethylene phosphate complexing agent is added respectively, and after stirring evenly, it is a suspension that the total solid content of the silica sol is 20%. Among them, the solid content of the first silica sol is 0%, 20%, 5%, 10%, and 15%, and then the pH is adjusted to 11.3 with sodium hydroxide solution or potassium hydroxide solution, ...

Embodiment 2

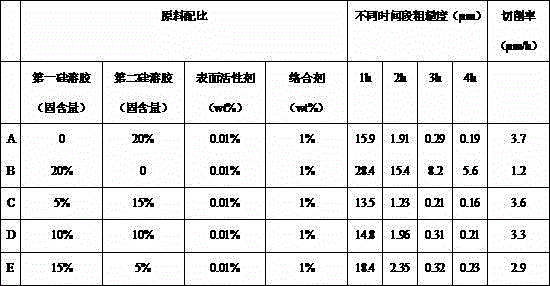

[0039] Prepare five polishing solutions A, B, C, D, E:

[0040]Weigh the first particle size silica sol, the second particle size silica sol, surfactant, complexing agent and water according to the weight ratio, add 0.1g N-acyl amino acid salt to 590g, 490g, 515g, 540g, 565g water respectively Surfactant, dissolve completely, add 400g, 0g, 100g, 200g, 300g of silica sol with a solid content of 50% and a particle size of 80nm after stirring evenly, add 0g, 500g, 375g after stirring evenly , 250g, 125g solid content is 40%, particle size is the second particle size silica sol of 200nm, after stirring well, respectively add 10g amine trimethylene phosphate complexing agent, form the silica sol total solid content after stirring well is 20% suspension, wherein, the solid content of the first silica sol is 20%, 0%, 5%, 10%, 15%, and then adjust the pH to 11.3 with sodium hydroxide solution or potassium hydroxide solution, and configure five parts of solid content It is 20% polishi...

Embodiment 3

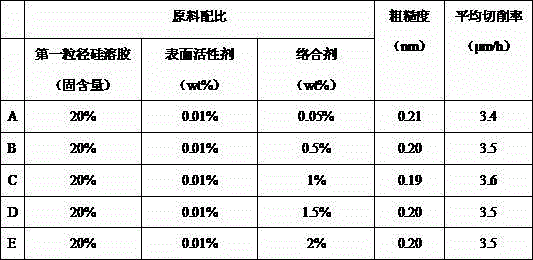

[0046] Prepare four polishing solutions A, B, C, D:

[0047] Weigh the first particle size silica sol, second particle size silica sol, surfactant, complexing agent and water according to the weight ratio, add 0.02g, 0.1g, 1g, 9g to 565g, 565g, 564g, 556g of water respectively N-acyl amino acid salt surfactant, add 125g solid content respectively after stirring and be 40%, the particle size is the first particle size silica sol of 20nm, after stirring, respectively add 300g solid content and be 50%, particle size is The second particle size silica sol of 90nm, after stirring evenly, respectively add 10g of amine trimethylene phosphate complexing agent, form the suspension that the total solid content of silica sol is 20% after stirring, wherein, the solid content of the first silica sol is 5%, then adjust the pH to 11.3 with sodium hydroxide solution or potassium hydroxide solution, and prepare four polishing solutions A, B, C, and D with a solid content of 20%.

[0048] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com