Vertical type spiral bamboo stick polishing machine

A polishing machine and bamboo stick technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of slow polishing speed of bamboo sticks, small amount of polishing at one time, labor-intensive, etc. To achieve the effect of saving manual discharge time, shortening polishing time and improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

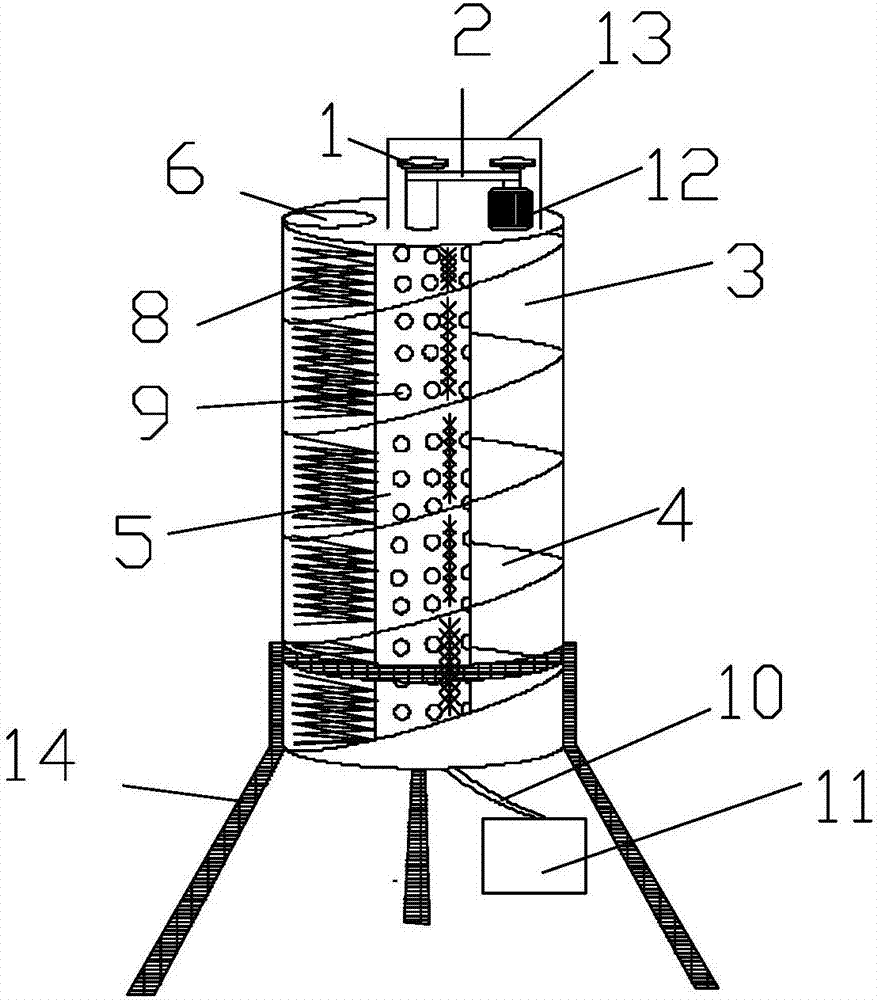

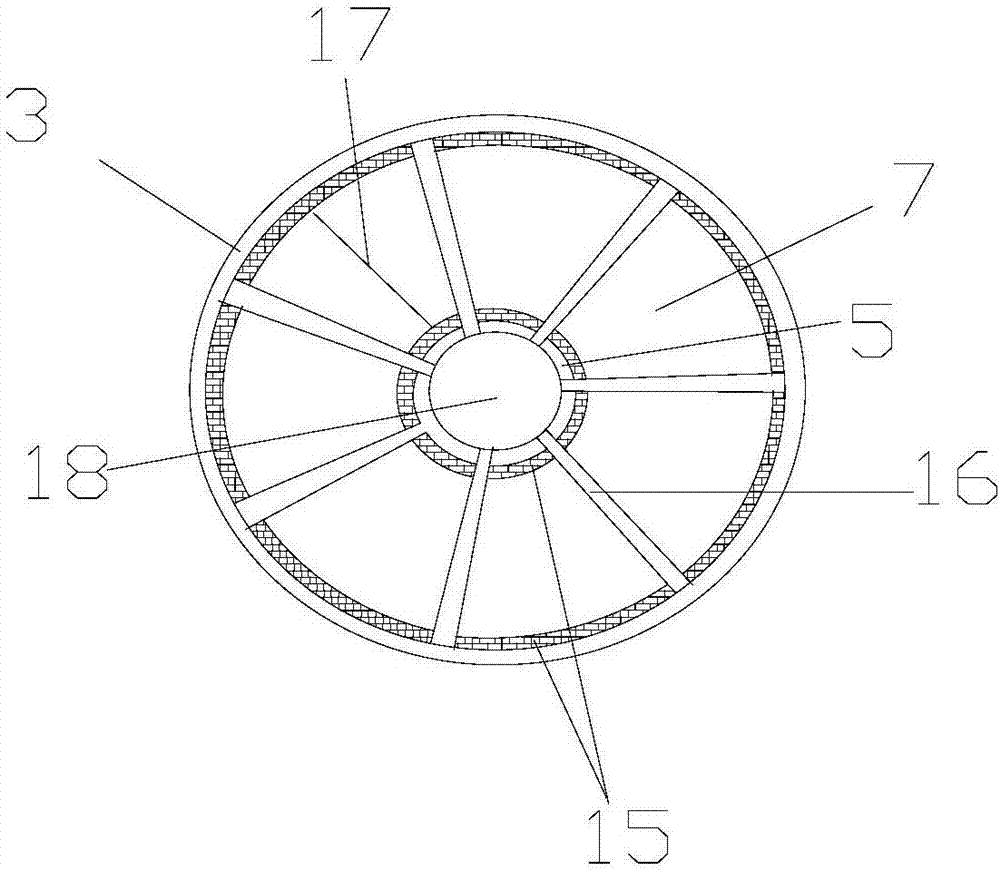

[0030] Please also see figure 1 and figure 2 , a vertical spiral bamboo stick polishing machine, comprising a frame 14 and a polishing cylinder 3 upright fixed on the frame 14. The vertical spiral bamboo stick polishing machine also includes a three-dimensional spiral disc 4, a cylindrical tube 5, a motor 12 and a vacuum cleaner 11, and the motor 12 is a variable frequency motor; the upper end of the polishing cylinder 3 is provided with a feed port 6, and the The lower end of the polishing cylinder 3 is provided with a discharge port 7 and a supporting rib 16; the polishing cylinder 3, the three-dimensional spiral disc 4 and the cylindrical tube 5 are mutually fitted from the outside to the inside, and the three-dimensional spiral disc 4 is fixed on the outer wall of the cylindrical tube 5 and Fitting with the outer wall of the cylindrical tube 5 and the inner wall of the polishing tube 3, the inner wall of the polishing tube and the outer wall of the cylindrical tube are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com