Composite polishing solution for metal polishing and preparation method thereof

A composite polishing and metal technology, applied in the field of metal polishing liquid, can solve problems such as low polishing efficiency, and achieve the effects of high polishing efficiency, improved brightness, and improved polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

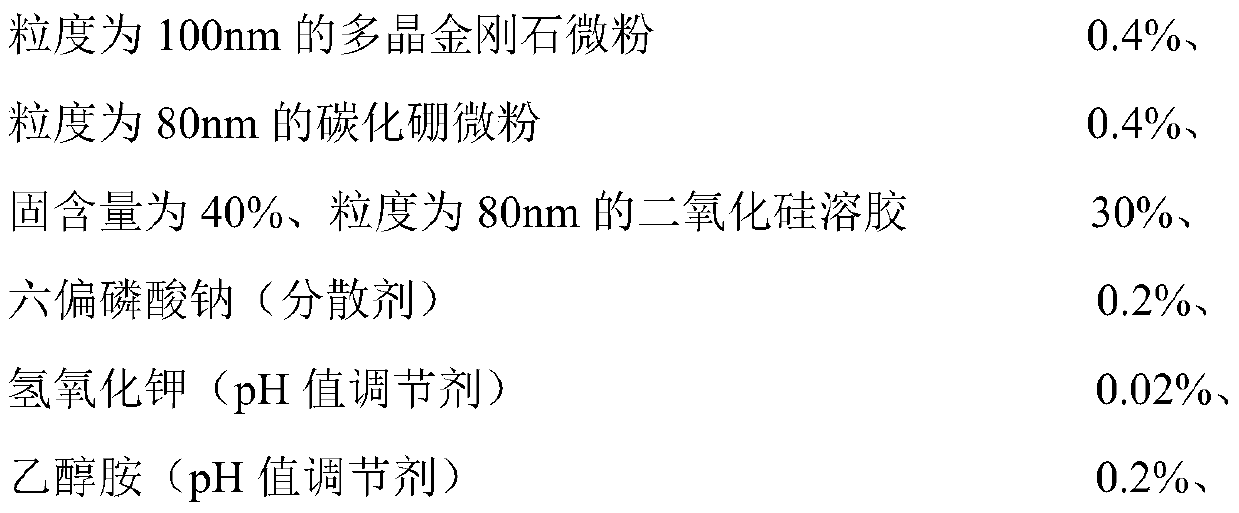

[0038] The composite polishing fluid for metal polishing of the present embodiment consists of the following components in mass percent:

[0039]

[0040]

[0041] The remainder is deionized water with a resistivity greater than 0.1 MΩ·cm.

[0042] The preparation method of the composite polishing liquid for metal polishing of the present embodiment comprises the following steps:

[0043] 1) Abrasive purification treatment: Take polycrystalline diamond micropowder and boron carbide micropowder respectively, add oxidizing acid (concentrated sulfuric acid), boil for 1 hour, let stand and cool for more than 1 hour until the abrasive sinks to the bottom of the container, and use a temperature not lower than 50°C The deionized water (resistivity greater than 0.1MΩ·cm) was repeatedly washed until the resistivity of the mixture of abrasive and water was greater than 0.02MΩ·cm, and the abrasive was dried for use; after purification, the impurity content on the surface of the abr...

Embodiment 2

[0047] The composite polishing fluid for metal polishing of the present embodiment consists of the following components in mass percent:

[0048]

[0049] The remainder is deionized water with a resistivity greater than 1 MΩ·cm.

[0050] The preparation method of the composite polishing liquid for metal polishing of the present embodiment comprises the following steps:

[0051] 1) Abrasive purification treatment: take polycrystalline diamond micropowder and boron carbide micropowder respectively, add oxidizing acid (nitric acid), boil for 1 hour, let stand and cool for more than 1 hour until the abrasive sinks to the bottom of the container, and use a temperature not lower than 50°C Wash with deionized water (resistivity greater than 0.1MΩ·cm) repeatedly until the resistivity of the mixture of abrasive and water is greater than 0.02MΩ·cm, then dry the abrasive and reserve it for later use; after purification, the impurity content on the surface of the abrasive is less than ...

Embodiment 3

[0055] The composite polishing fluid for metal polishing of the present embodiment consists of the following components in mass percent:

[0056]

[0057] The remainder is deionized water with a resistivity greater than 10 MΩ·cm.

[0058] The preparation method of the composite polishing liquid for metal polishing of the present embodiment comprises the following steps:

[0059] 1) Abrasive purification treatment: take polycrystalline diamond micropowder and boron carbide micropowder respectively, add oxidizing acid (perchloric acid), boil for 1 hour, let stand and cool for more than 1 hour until the abrasive sinks to the bottom of the container, and use a temperature not lower than 50 ℃ of deionized water (resistivity greater than 0.1MΩ·cm) was washed repeatedly until the resistivity of the mixture of abrasive and water was greater than 0.02MΩ·cm, and the abrasive was dried for later use; after purification, the impurity content on the abrasive surface was lower than 100pp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com