Polishing disk capable of adjusting regional pressure

A polishing disc and pressure technology, used in abrasives, grinding tools, metal processing equipment, etc., can solve the problem of uneven polishing pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

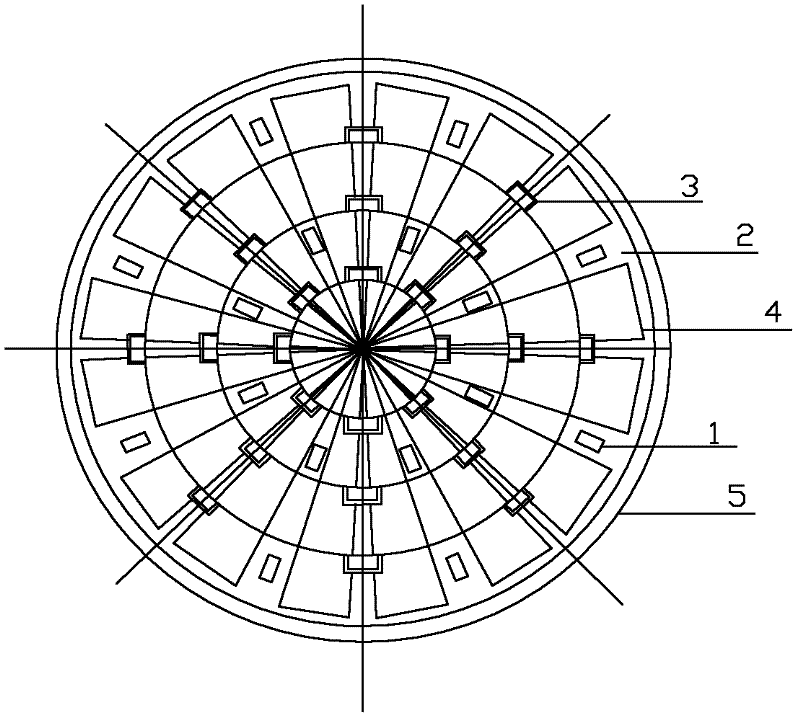

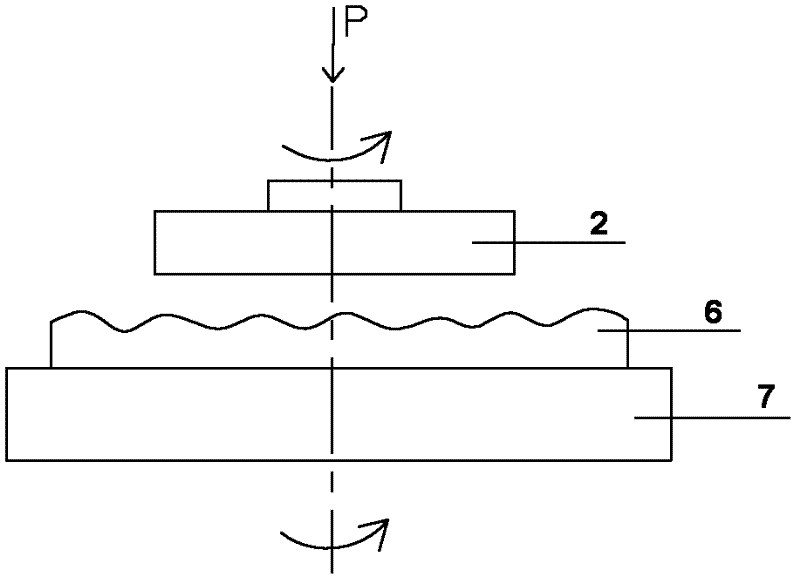

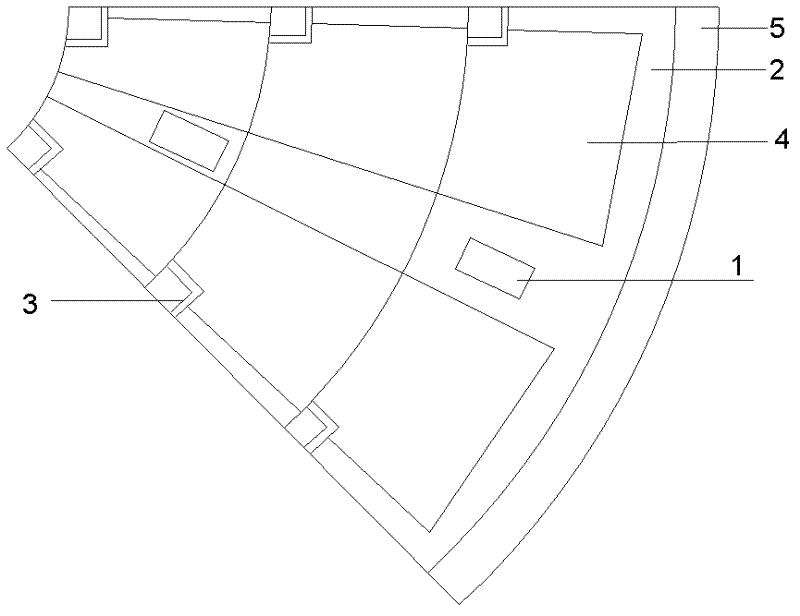

[0014] see Figure 1~3 , the embodiment of the present invention is provided with piezoelectric sensor 1, polishing disc 2, slider chute pair 3, polyurethane polishing sheet 4 and round chuck 5; Described polishing disc 2 is provided with at least 2 circular rings and is divided into sectors block, the fan-shaped block is provided with a slider chute pair 3, and each fan-shaped block surface is pasted with 2 pieces of polyurethane polishing sheets 4, and between the 2 pieces of polyurethane polishing sheets 4, there is an inward hole for placing the piezoelectric sensor 1. The groove; The round chuck 5 used to fix the sector block is located on the outer edge of the polishing disc 2.

[0015] The polishing disc is divided into multiple fan-shaped blocks, and the pressure adjustment structure of the corresponding size can be combined according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com