Polishing and cleaning process for precision component

A component and precision technology, which is applied in the direction of polishing composition containing abrasives, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problem of reducing the surface adsorption force of particles and precision components, difficult to remove sub-micron particles, Physical damage and other problems on the surface of precision components, to achieve good polishing effect, prevent settlement, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A polishing and cleaning process for precision components, the polishing and cleaning process comprises the following steps:

[0043] (1) Polishing:

[0044] (a) Preparation of polishing mold: Melt solid 55# polished asphalt into liquid 55# polished asphalt at 45°C, add alumina powder to the above liquid 55# polished asphalt, the mass ratio of 55# polished asphalt to alumina powder 3:1, stir and mix evenly to obtain a mixed solution of 55# polished pitch and alumina powder, pour the above mixed solution on a flat substrate, cool naturally, and solidify to obtain a polishing mold, groove the surface of the polishing mold, and the depth of the groove is is 1mm, the groove width is 1mm, and the groove is used to hold the polishing liquid;

[0045] (b) Fix the polishing mold on the grinding machine spindle, pour polishing liquid on the surface of the polishing mold, press the precision components to be polished on the polishing mold, turn on the grinding machine, the rotat...

Embodiment 2

[0052] A polishing and cleaning process for precision components, the polishing and cleaning process comprises the following steps:

[0053] (1) Polishing:

[0054] (a) Preparation of polishing mold: Melt solid 64# polishing asphalt into liquid 64# polishing asphalt at 50°C, add alumina powder to the above liquid 64# polishing asphalt, the mass ratio of 64# polishing asphalt to alumina powder 4:1, stir and mix evenly to obtain a mixed solution of 64# polished pitch and alumina powder, pour the above mixed solution on a flat substrate, cool naturally, and solidify to obtain a polishing mold, groove the surface of the polishing mold, the depth of the groove is 2mm, the groove width is 1.5mm, the groove is used to hold the polishing liquid;

[0055] (b) Fix the polishing mold on the grinding machine spindle, pour polishing liquid on the surface of the polishing mold, press the precision components to be polished on the polishing mold, turn on the grinding machine, the rotating s...

Embodiment 3

[0062] A polishing and cleaning process for precision components, the polishing and cleaning process comprises the following steps:

[0063] (1) Polishing:

[0064] (a) Preparation of polishing mold: Melt solid 73# polished asphalt into liquid 73# polished asphalt at 70°C, add alumina powder to the above liquid 73# polished asphalt, the mass ratio of 73# polished asphalt to alumina powder 7:1, stir and mix evenly to obtain a mixed solution of 73# polished pitch and alumina powder, pour the above mixed solution on a flat substrate, cool naturally, and solidify to obtain a polishing mold, groove the surface of the polishing mold, and the depth of the groove is is 3mm, the groove width is 2mm, and the groove is used to hold the polishing liquid;

[0065] (b) Fix the polishing mold on the grinding machine main shaft, pour polishing liquid on the surface of the polishing mold, press the precision components to be polished on the polishing mold, open the grinding machine, the rotat...

PUM

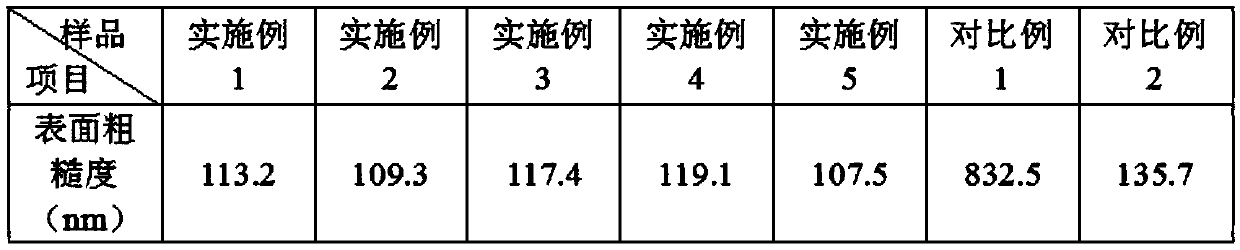

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com