Method for preparing sample showing metallurgical structure of tantalum-tungsten alloy

A technology of metallographic structure and tantalum-tungsten alloy, which is applied in the field of preparing tantalum-tungsten alloy metallographic samples and displaying the structure, can solve the problems such as the difficulty of displaying the grain structure, and achieve the effect of simple implementation, solution to display difficulties, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

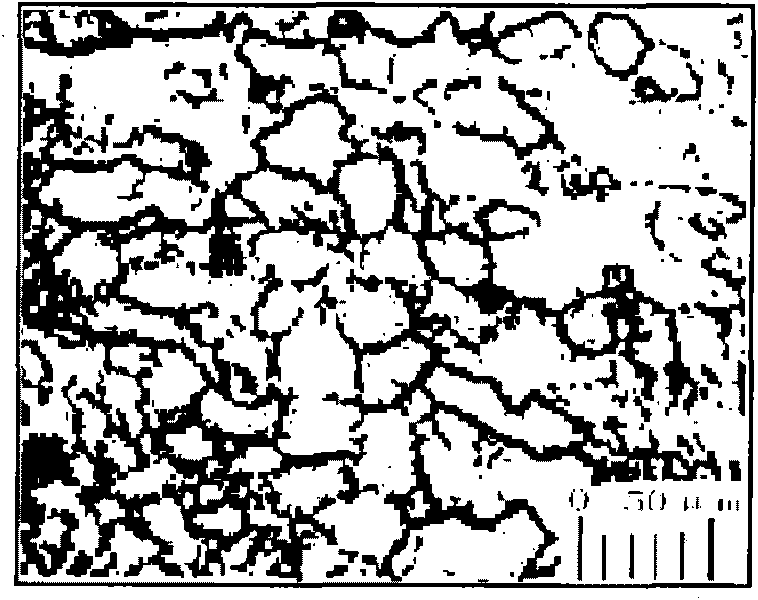

Embodiment 1

[0026] 1. Coarse grinding: The tantalum-tungsten alloy sample is polished by 200#, 400#, 600#, 800#, 1000#, 1500#, 2000# silicon carbide water sandpaper in sequence, and water is used as lubricant, which is changed every time during grinding For sandpaper, the sample should be rotated 90 degrees in the same direction, and the surface of the sample should be observed with a microscope to determine the state of the grinding surface;

[0027] 2. Cleaning: Hold the coarsely ground sample with tweezers, put it in the cleaning solution for cleaning, after cleaning for 30 seconds, put it in clean water to rinse;

[0028] 3. Fine grinding: Carry out fine grinding on diamond grinding paper with a particle size of 1 μm. First, grind away the rough grinding scratches along the direction perpendicular to the rough grinding scratches, then turn 90 degrees, and grind again. Observe the surface state and confirm that the surface scratches are in the same direction;

[0029] 4. Cleaning: Hol...

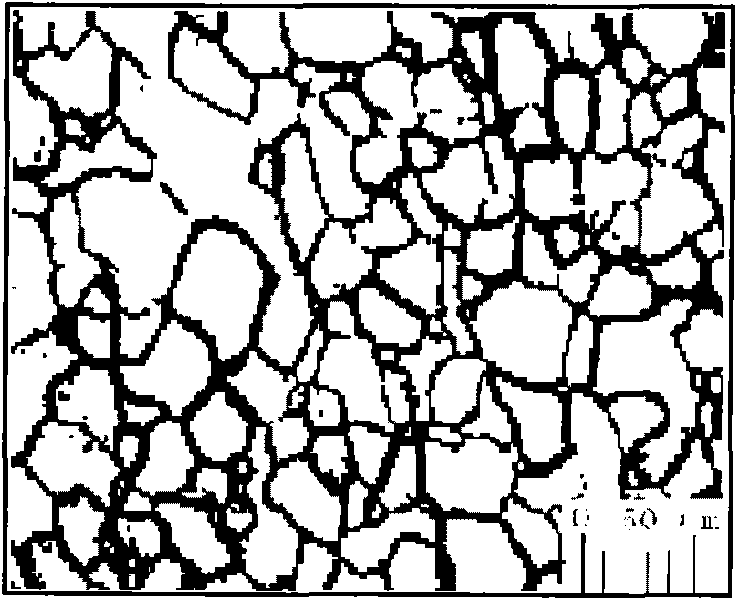

Embodiment 2

[0033] 1. Coarse grinding: The tantalum-tungsten alloy sample is polished by 200#, 400#, 600#, 800#, 1000#, 1500#, 2000# silicon carbide water sandpaper in sequence, and water is used as lubricant, which is changed every time during grinding For sandpaper, the sample should be rotated 90 degrees in the same direction, and the surface of the sample should be observed with a microscope to determine the state of the grinding surface;

[0034] 2. Cleaning: Hold the coarsely ground sample with tweezers, put it in the cleaning solution for cleaning, after cleaning for 45 seconds, put it in clean water to rinse;

[0035] 3. Fine grinding: Carry out fine grinding on diamond grinding paper with a particle size of 1 μm. First, grind away the rough grinding scratches along the direction perpendicular to the rough grinding scratches, then turn 90 degrees, and grind again. Observe the surface state and confirm that the surface scratches are in the same direction;

[0036] 4. Cleaning: Cla...

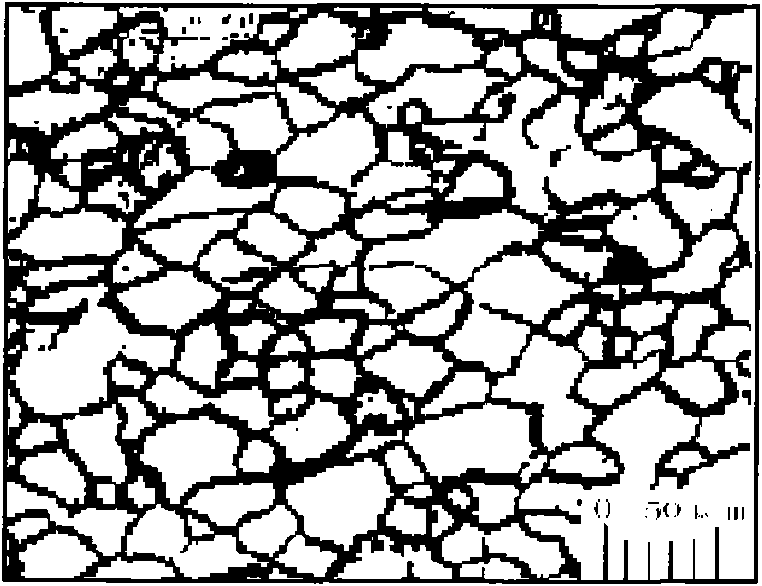

Embodiment 3

[0040] 1. Coarse grinding: The tantalum-tungsten alloy sample is polished by 200#, 400#, 600#, 800#, 1000#, 1500#, 2000# silicon carbide water sandpaper in sequence, and water is used as lubricant, which is changed every time during grinding For sandpaper, the sample should be rotated 90 degrees in the same direction, and the surface of the sample should be observed with a microscope to determine the state of the grinding surface;

[0041] 2. Cleaning: Hold the coarsely ground sample with tweezers, put it in the cleaning solution for cleaning, after cleaning for 60 seconds, put it in clean water to rinse;

[0042] 3. Fine grinding: Carry out fine grinding on diamond grinding paper with a particle size of 1 μm. First, grind away the rough grinding scratches along the direction perpendicular to the rough grinding scratches, then turn 90 degrees, and grind again. Observe the surface state and confirm that the surface scratches are in the same direction;

[0043] 4. Cleaning: Cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com