Deburring tool for new energy automobile air conditioner electromagnetic clutch hub machining

An electromagnetic clutch and new energy vehicle technology, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of long processing time, low processing efficiency, cumbersome installation process, etc., and achieve fast and stable fixation The effect of the hub

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

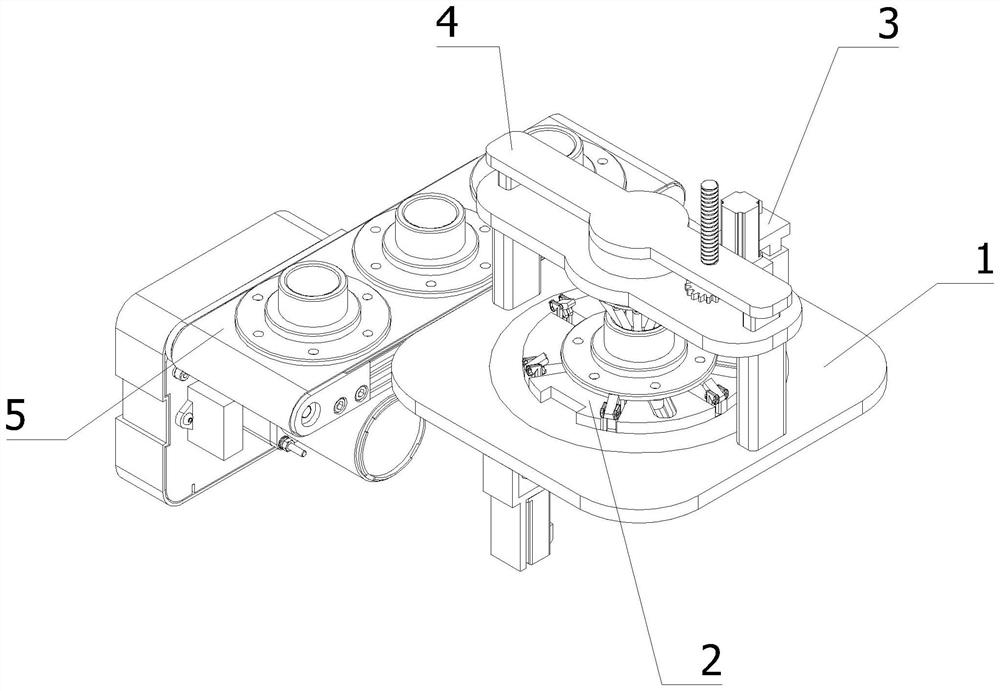

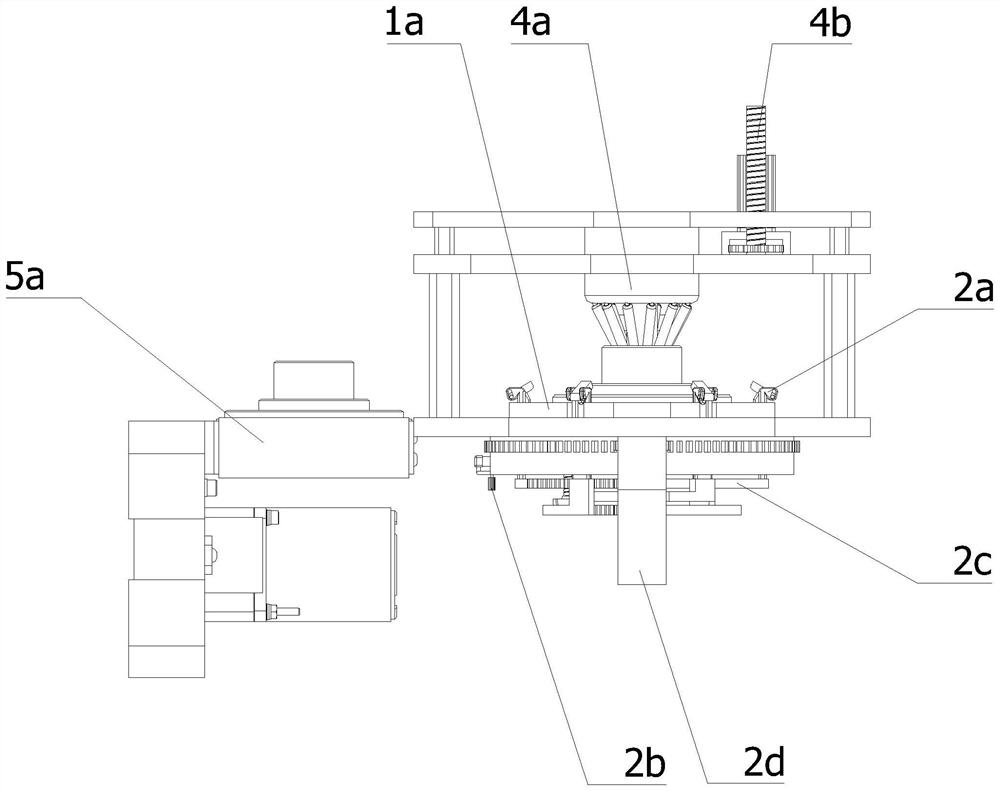

[0045] like Figure 1-10 shown:

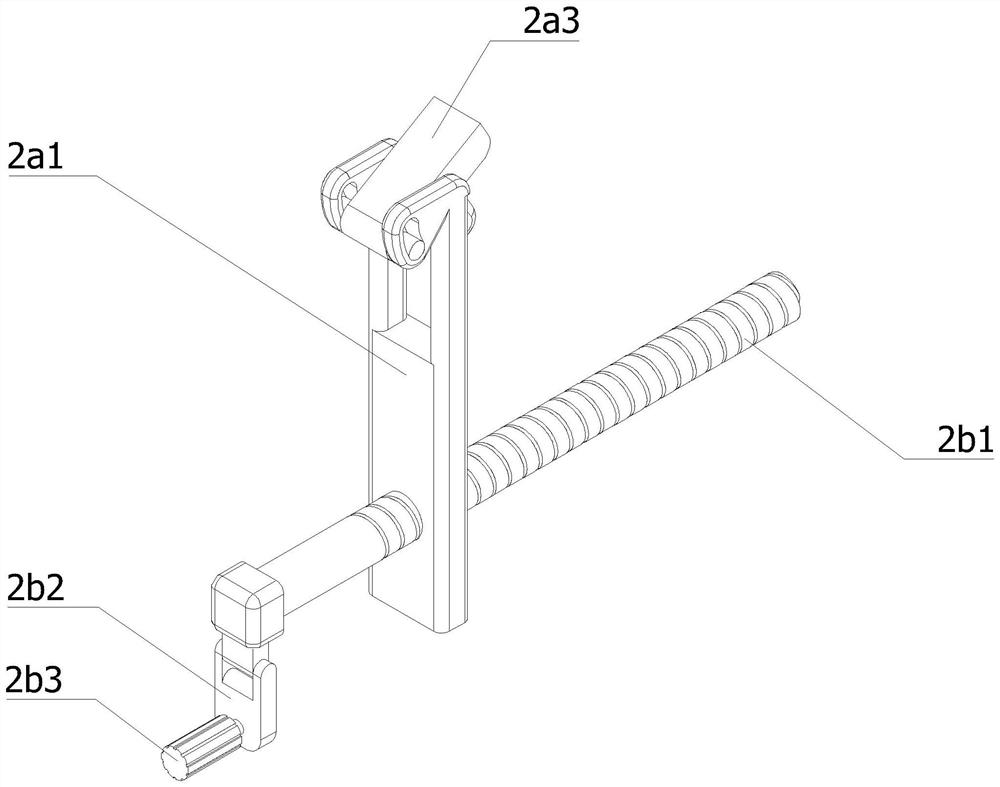

[0046] A deburring tool for machining an electromagnetic clutch hub of a new energy vehicle air conditioner, comprising a frame 1 and a grinding assembly 3, wherein the grinding assembly 3 is mounted on the frame 1; the frame 1 includes a rotary table 1a, and a plurality of The first slide rail 1a1; also includes a fixing device 2, the fixing device 2 includes a clamping jaw 2a and a linear drive assembly 2b, the clamping jaws 2a are provided with a plurality of and correspond to the first slide rail 1a1 one-to-one, and the clamping jaws 2a include a first installation The seat 2a1, the fixed shaft 2a2, the chuck 2a3 and the torsion spring 2a4, the first mounting seat 2a1 is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com