Heat preservation and exhaust corrugated pipe structure

A corrugated pipe and corrugated technology, which is applied in the field of thermal insulation and exhaust corrugated pipe structure, can solve the problems that the shock absorption effect needs to be improved, the thermal insulation effect is reduced, and the thermal insulation layer is easy to wear, so as to avoid uneven displacement of materials and avoid structural interference. Or the effect of severe friction to ensure the uniformity of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

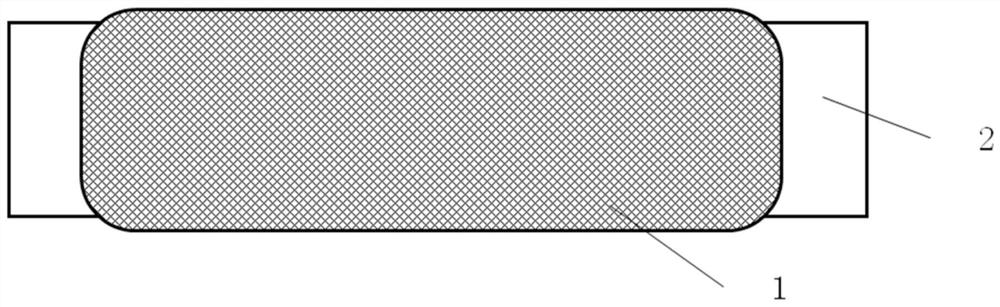

[0026] Such as image 3 As shown, a thermal insulation exhaust bellows structure includes a thermal insulation outer tube 1 and a corrugated inner tube 2, and both ends of the thermal insulation outer tube 1 are fixedly connected to both ends of the corrugated inner tube 2. Specifically, both ends of the thermal insulation outer tube 1 include connecting sections, and the thermal insulation outer tube is fixedly connected to the corrugated inner tube 2 through the connecting section. In this embodiment, the connecting section and the corrugated inner tube 2 are connected by welding.

[0027] In this embodiment, the corrugated inner tube 2 is a conventionally used stainless steel corrugated inner tube.

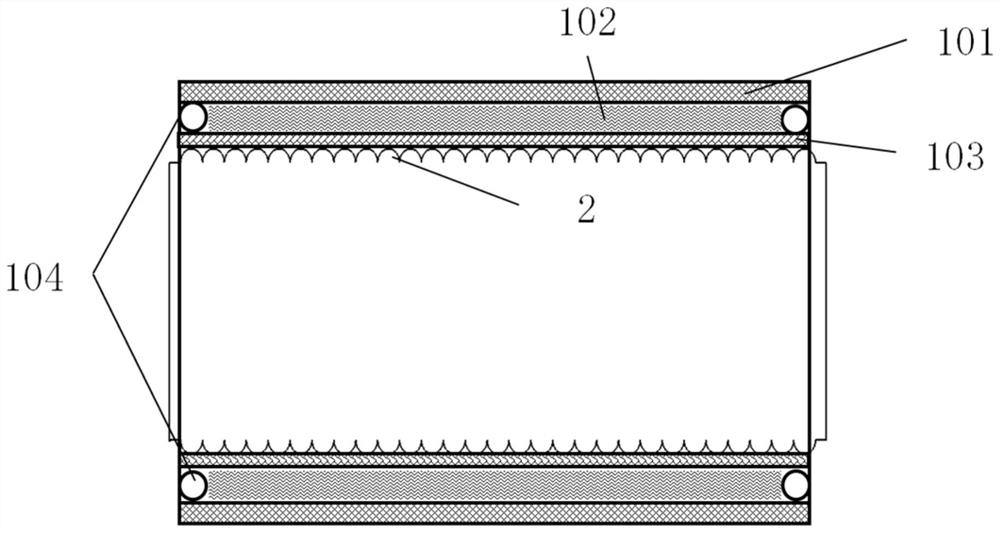

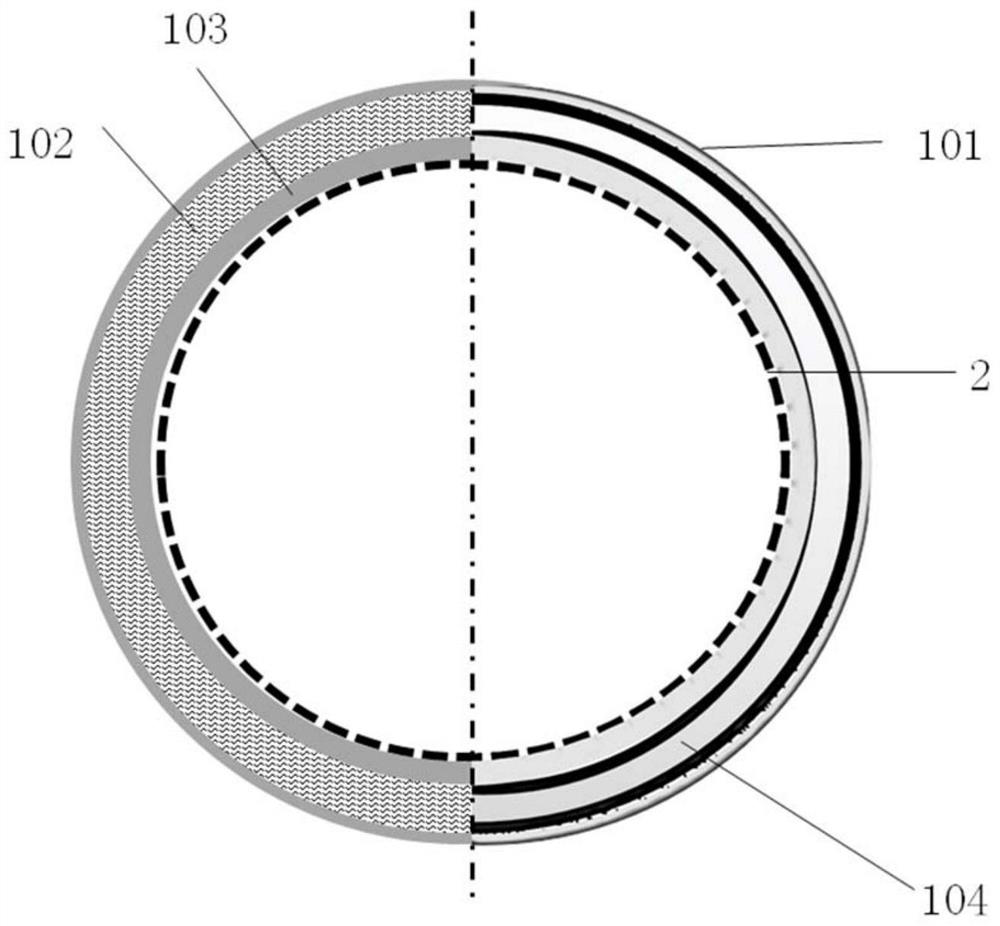

[0028] Such as figure 1 and figure 2 As shown, the thermal insulation outer pipe 1 includes an outer layer 101, a middle layer 102 and an inner layer 103, the inner layer 103 is covered on the outer surface of the corrugated inner pipe 2, the middle layer 102 is covered on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com