Wear-resisting device of receiving liner plate of band conveyor

A belt conveyor and anti-wear technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problem of too fast wear of the liner, achieve the effects of avoiding severe friction, reducing wear, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

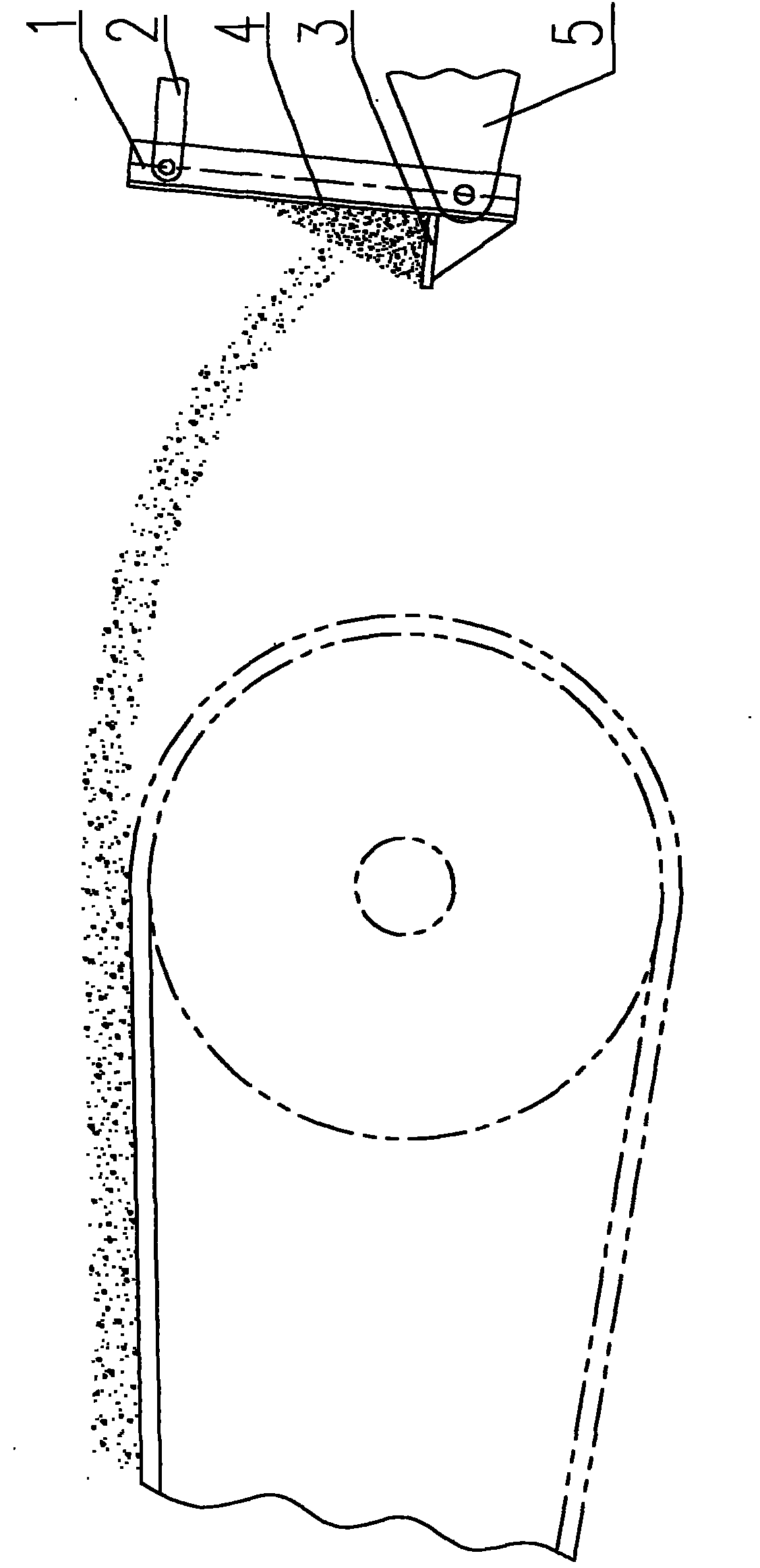

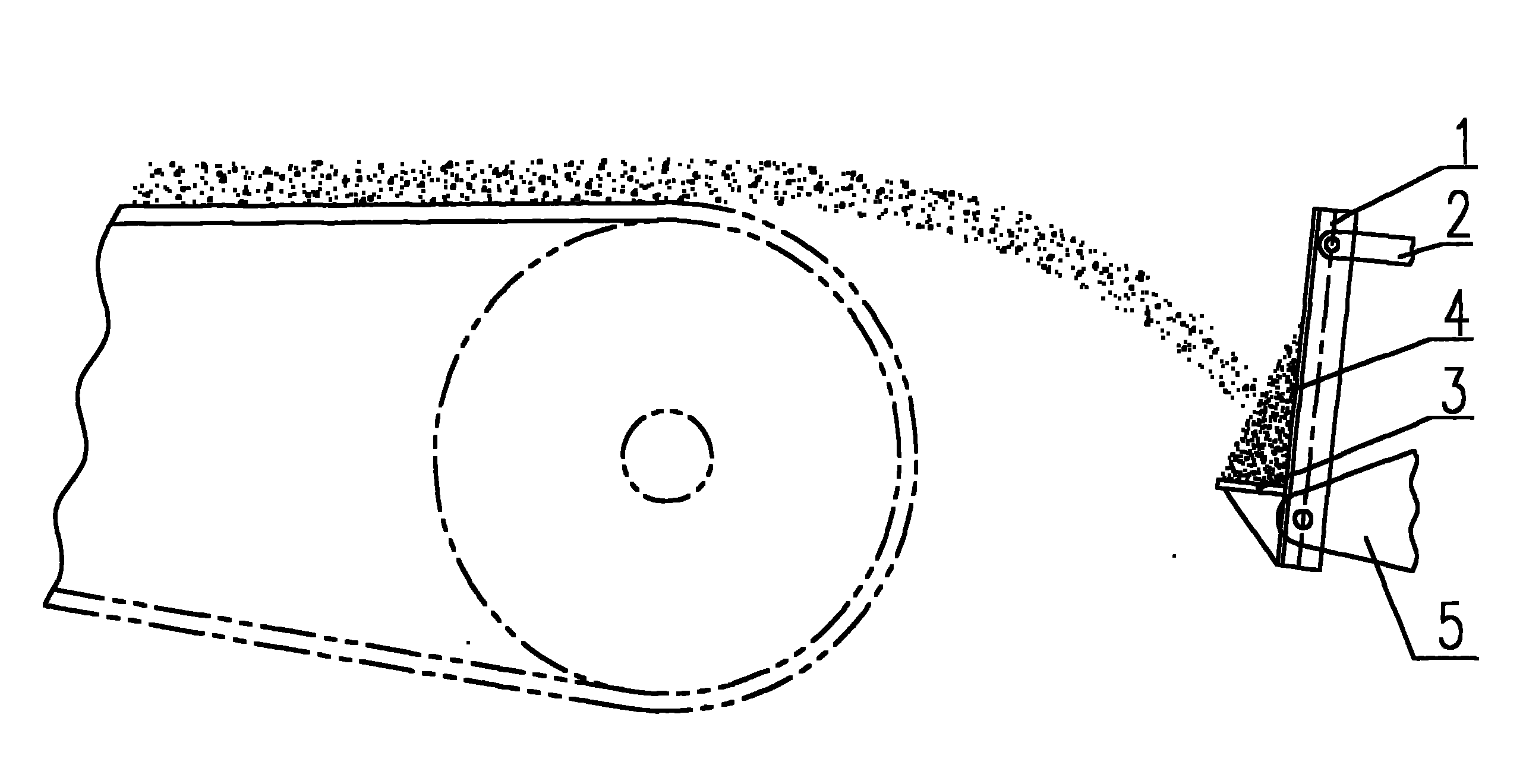

[0011] Such as figure 1 As shown, an anti-wear device for the liner of a belt conveyor is composed of a bracket 1 installed on a conveyor frame 5, a liner 4 fixed on the bracket 1, an adjusting rod 2 and a baffle 3.

[0012] It is welded (feed plate) 3 at a certain angle with the support 1, the upper part of the support 1 is connected with the adjusting rod 2, and the lower part of the support 1 is hinged with the conveyor frame 5.

[0013] Due to the different running speeds of the materials, the positions where they fall on the lining board are also different. In order to make the materials directly fall on the accumulated materials on the baffle, the support 1 is designed to be adjustable. The angle of the bracket 1 can be adjusted through the adjusting rod 2 hinged thereto.

[0014] According to actual working conditions, the present invention can be installed on the discharge end or the material receiving end of the belt conveyor.

[0015] Working process of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com