Positive Yarn Guide Mechanism of Computerized Flat Knitting Machine

A technology of yarn guide mechanism and flat knitting machine, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of yarn tightness and looseness, high probability of yarn breakage, and affecting fabric quality, so as to avoid violent Friction, reduce the probability of yarn breakage, and ensure the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

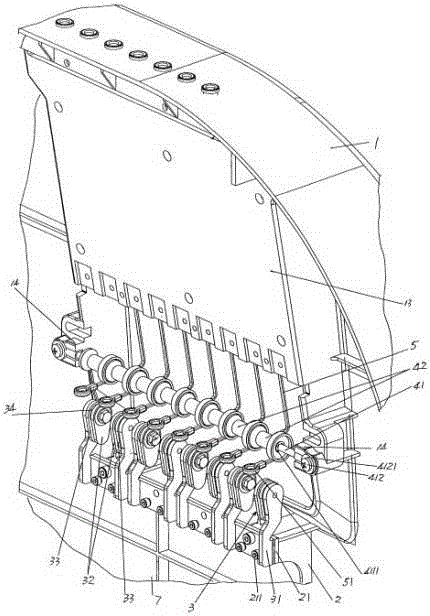

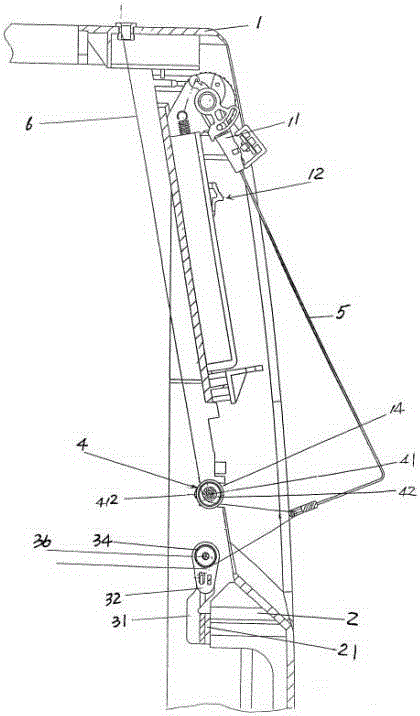

[0022] See figure 1 , a bedside box 1 belonging to the structural system of the computerized flat knitting machine is provided, and the bedside box 1 is fixed on a frame 7 ( figure 2 shown) and usually at the top end of rack 7.

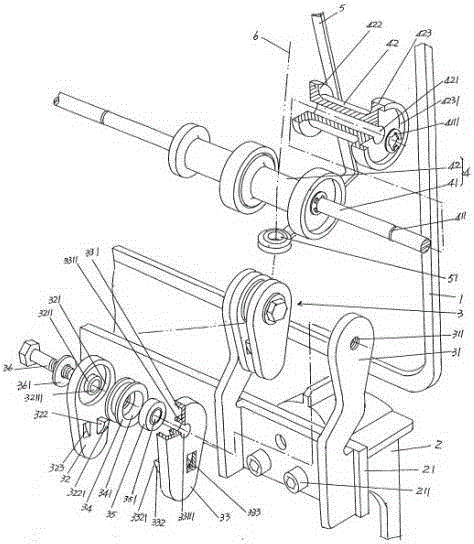

[0023] The sliding sleeve yarn guiding device 4, the fixed plate seat 2 and the pulley yarn guiding device 3 belonging to the structural system of the positive yarn guiding mechanism of the present invention are provided, the sliding sleeve yarn guiding device 4 is arranged on the aforementioned bedside box 1, and Located below the height direction of the bedside box 1, the fixed plate seat 2 is fixed on the top of the aforementioned frame 7, and a thread guide pulley seat fixed plate 21 is fixed on the fixed plate seat 2 with the thread guide pulley seat fixed plate screw 211 , the yarn guide pulley seat fixing plate 21 corresponds to the bottom of the aforementioned sliding sleeve yarn guiding device 4, and is laterally parallel to the sliding sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com