Blade and impeller of vertical shaft wind driven generator

A wind turbine, vertical shaft technology, applied in the field of blades and impellers, can solve the problems of aggravated friction and cutting action, large starting torque, and poor operation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

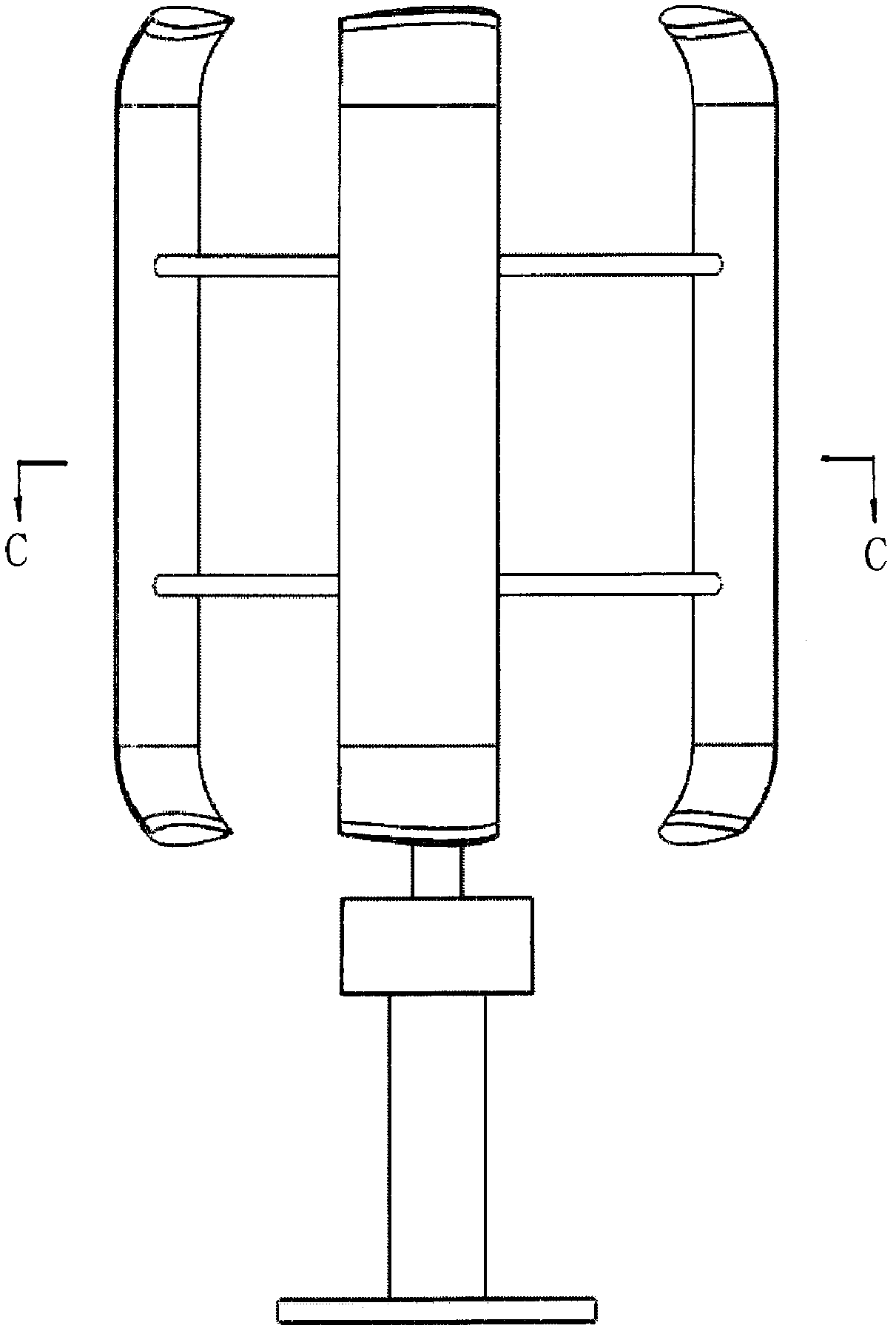

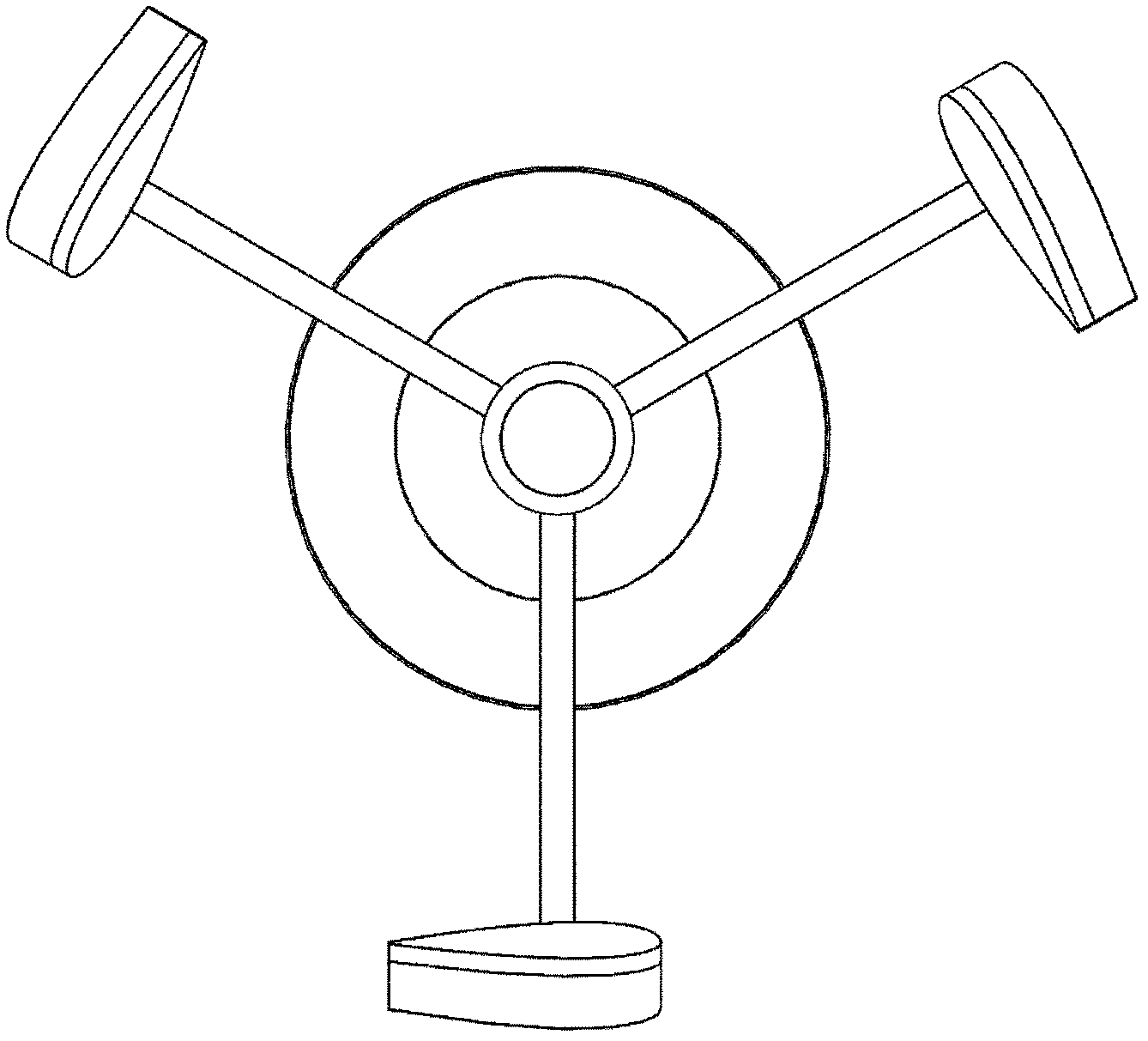

[0023] The blade and impeller of the vertical axis wind power generator of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

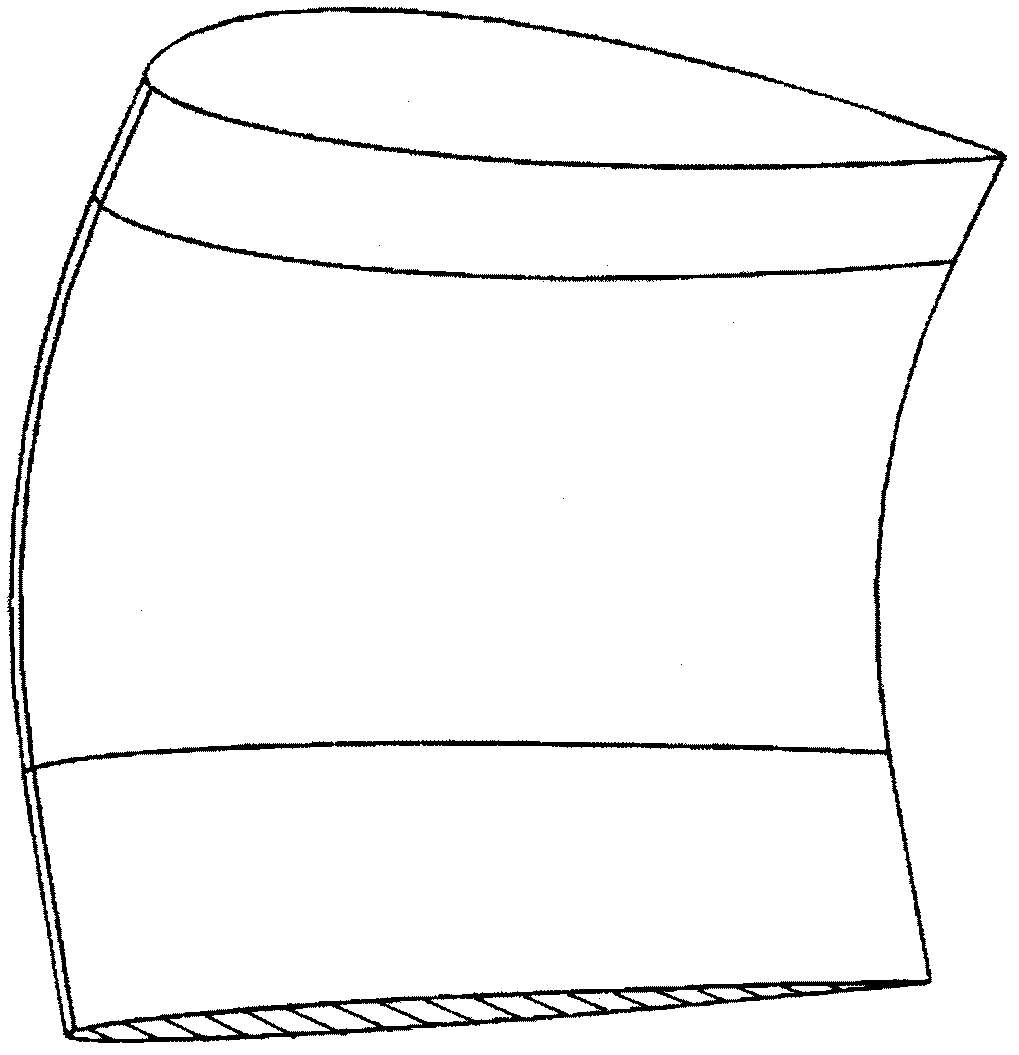

[0024] Such as Figure 4 Shown, the cross-section of the blade of the vertical axis wind power generator of the present invention is an airfoil, and the airfoil referred to in the present invention refers to the streamlined cross-section of the wing. The lift force is distributed in the shape of a bird's wing, and the lift force can provide power for the rotation of the impeller. The blade cross section of the present invention can be any airfoil shape. This embodiment adopts the symmetrical airfoil shape described by the following coordinates, (1.0000, 0.00158), (0.9500, 0.01008) , (0.9000, 0.01810), (0.8000, 0.03279), (0.7000, 0.04580), (0.6000, 0.05704), (0.5000, 0.06617), (0.4000, 0.07254), (0.3000, 0.07502), (0.2702), (0.2704) 0.2000, 0.07172), (0.1500, 0.06682...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com