A mold device

A mold and template technology, applied in the field of mold devices, can solve the problems of lower precision, increased cost, damage to the upper mold barrel, etc., and achieve the effects of reducing wear, reducing maintenance costs, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] As mentioned in the background technology section, the upper mold barrel of the current mold device is not only easy to wear, but also very inconvenient to replace the upper mold barrel.

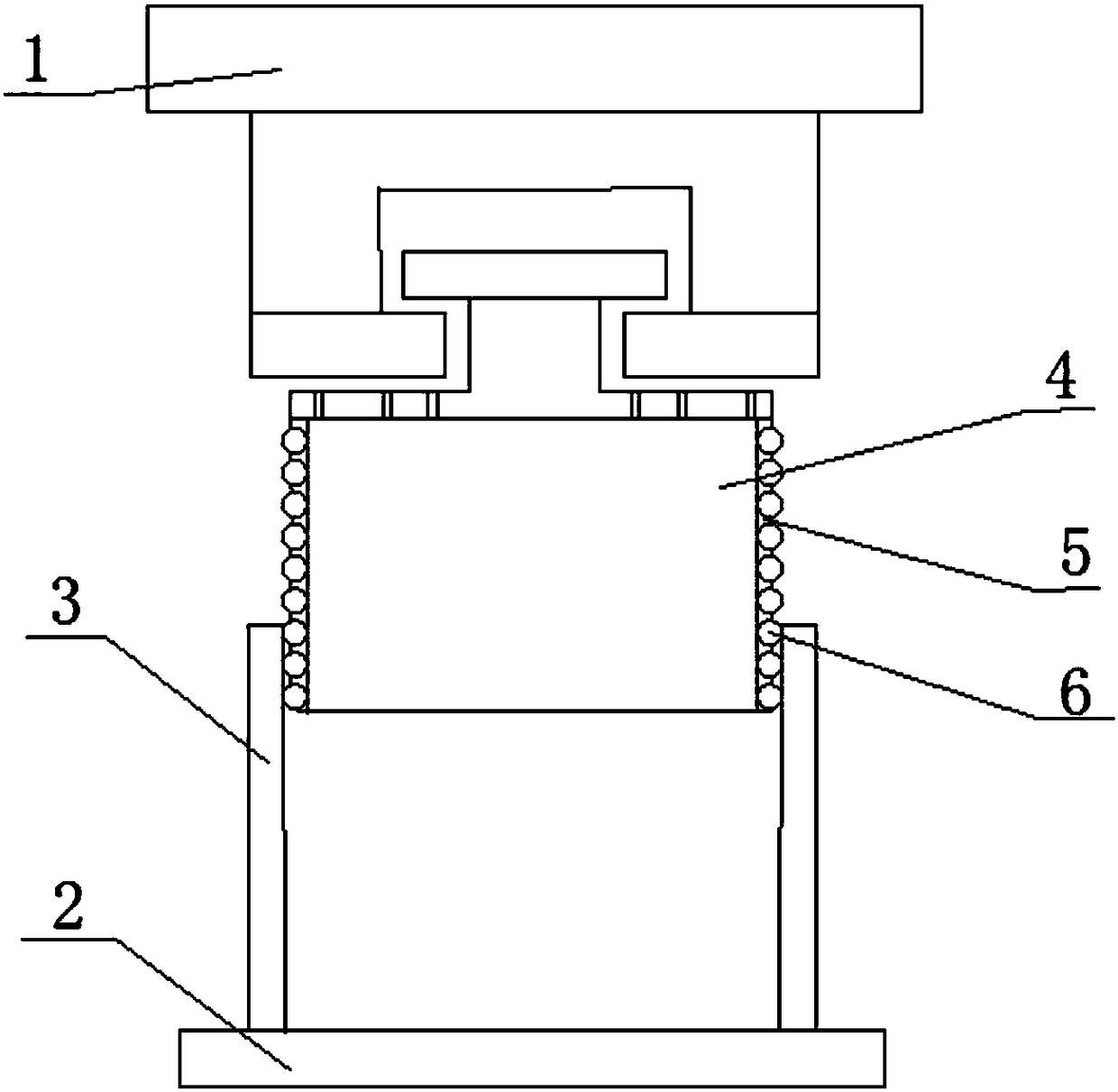

[0022] On the basis of the above research, the embodiment of the present invention provides a mold device. Through the multiple balls arranged on the side wall of the copper sleeve, when the upper mold barrel slides in the lower mold barrel, the outer side of the upper mold barrel can be avoided. The wall and the inner side wall of the lower mold barrel cause severe friction due to direct contact, and at the same time, because the ball can roll in the second through hole on the copper sleeve, the friction between the steel ball and the upper mold barrel and the lower mold barrel can be reduced, thereby reducing the friction of the upper mold. Wear of barrel and die barrel. When the balls are greatly worn, remove the copper sleeve from the upper mold barrel, then replace the balls and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com