Integrated ABS sensor automobile hub bearing unit

A technology for automobile hubs and sensors, which is applied in the directions of hubs, vehicle parts, transportation and packaging, etc. It can solve the problems of unable to monitor the speed of inner and outer row rolling elements, and cannot obtain information, so as to shorten the braking distance, avoid severe friction, and reduce wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

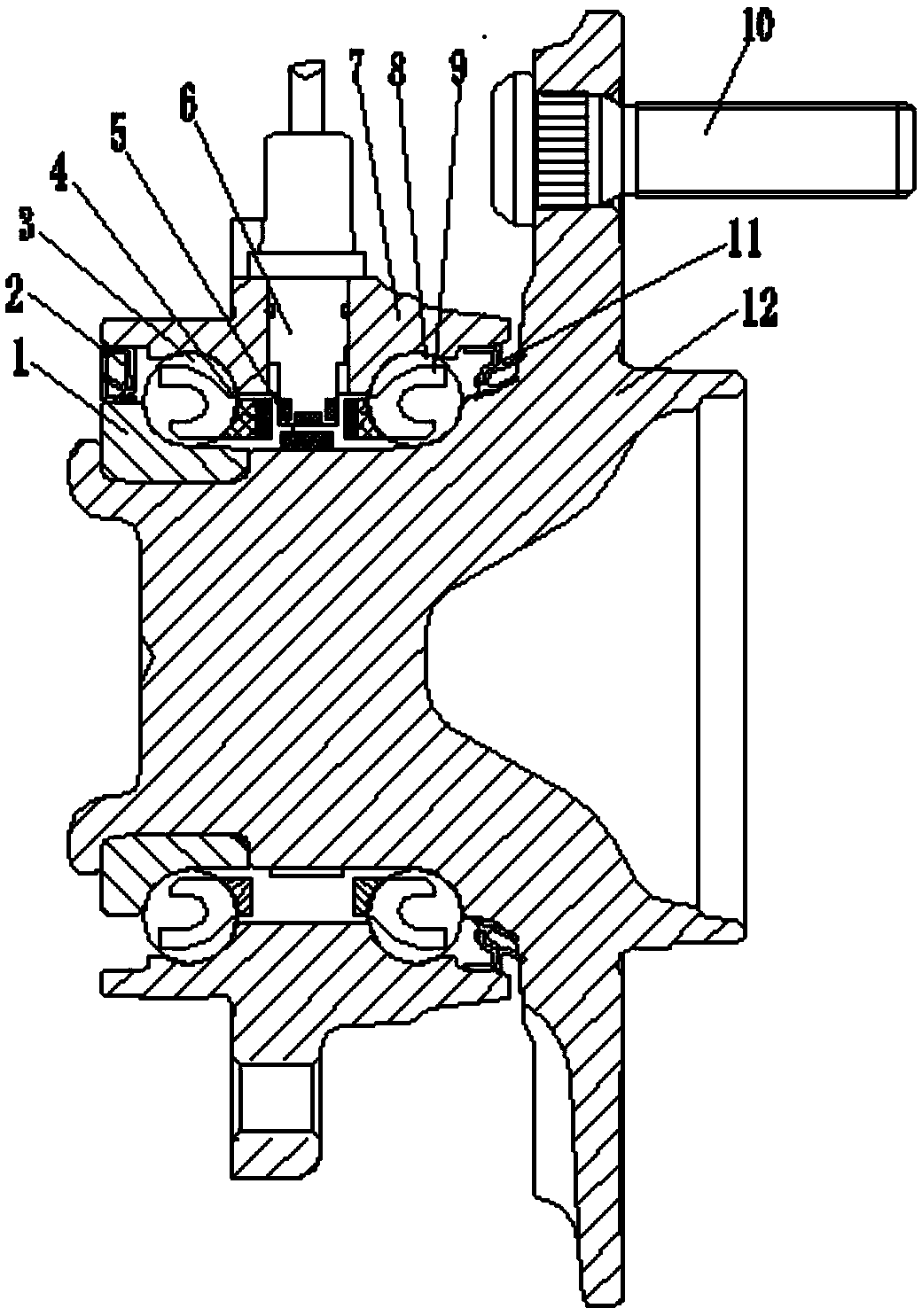

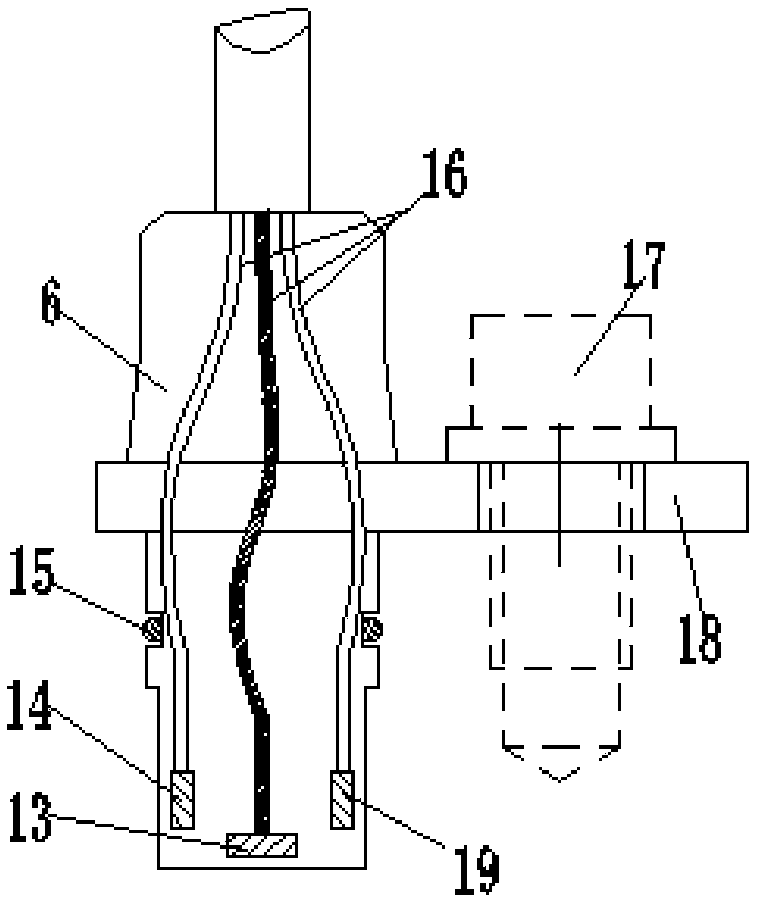

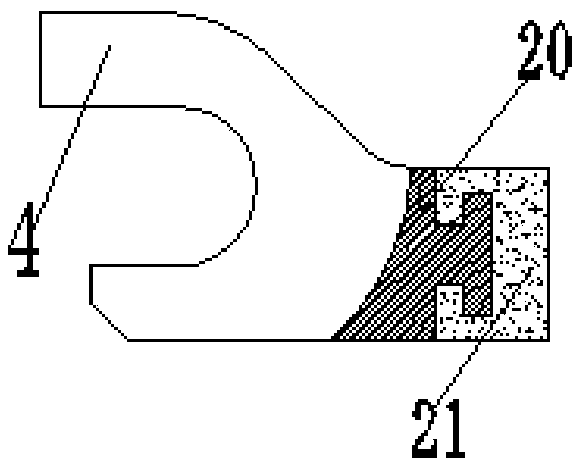

[0017] The embodiment of the present invention is as figure 1 , figure 2 and image 3 As shown, an integrated ABS sensor automobile hub bearing unit, an inner ring 1 is installed and fixed on the outer circle of the left end of the inner flange, and a first raceway is provided between the inner ring 1 and the outer flange 7; the first The first magnetic cage 4 is installed in the raceway, and the first rolling element 3 is installed in the pocket of the first magnetic cage 4; the first sealing ring 2 is arranged between the inner ring 1 and the outer flange 7; A second raceway is provided between the outer circular surface of the other end of the blue plate 12 and the inner circular surface of the outer flange, and a second magnetic retainer 9 is installed in the second raceway, and a second magnetic retainer 9 is installed in the pocket hole. The second rolling body 8, the root of the inner flange 12 and the outer flange 7 is provided with a second sealing ring 11; the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com