Hard sealed butterfly valve

A hard seal and butterfly valve technology, applied in the field of nuclear secondary hard seal butterfly valves, can solve the problems of misalignment between the butterfly plate and the valve seat, fluid leakage, etc., and achieve the effect of avoiding severe friction and ensuring sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

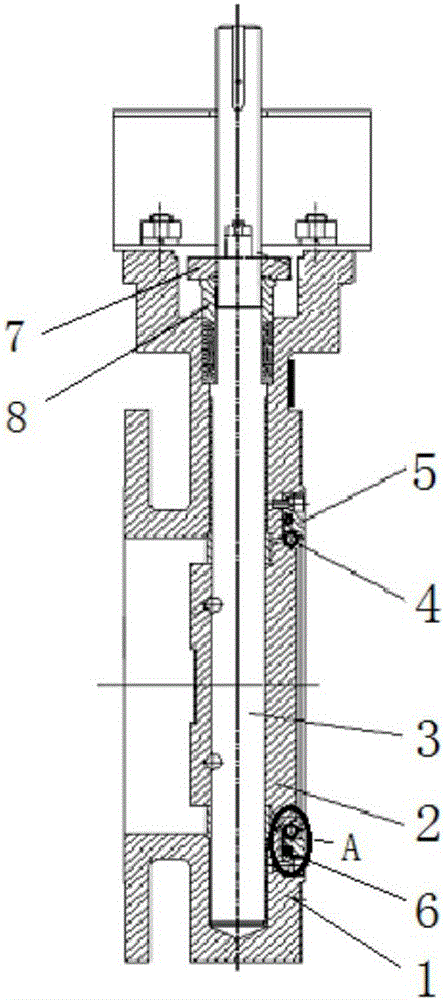

[0069] This embodiment provides a hard-sealed butterfly valve, including:

[0070] A valve body 1, a valve body channel is formed inside the valve body 1;

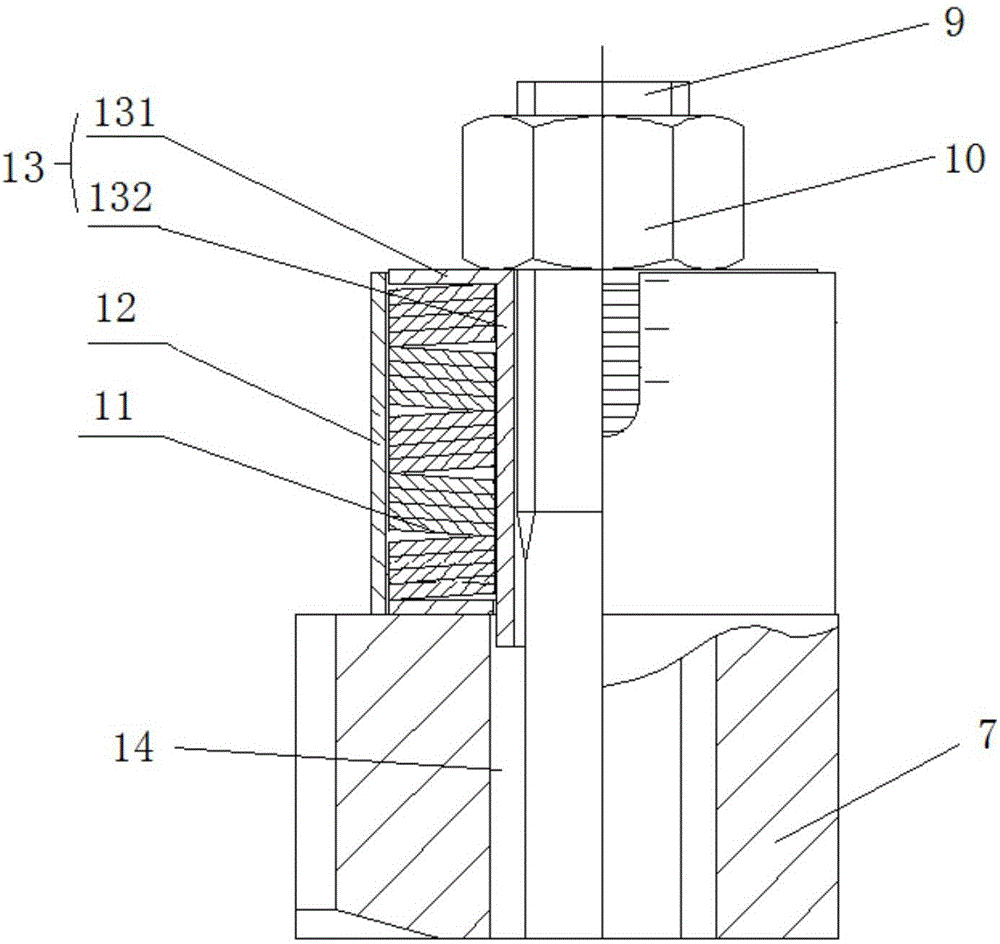

[0071] A valve stem 3, one end of which extends into the passage of the valve body;

[0072] The butterfly plate 2 is connected to the valve stem 3 and is located in the passage of the valve body;

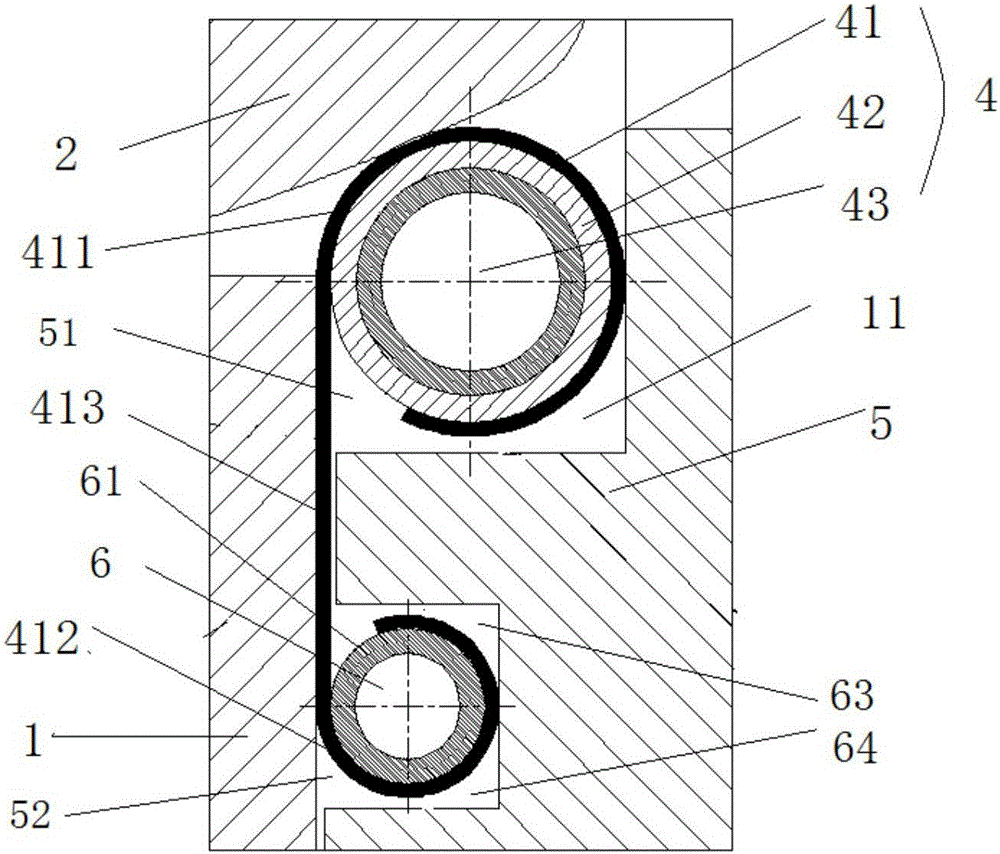

[0073] The valve seat pressure ring 5 is connected to the valve body 1 and has a first gap;

[0074] The first accommodating space 51 is formed between the valve body 1 and the first gap of the valve seat pressure ring 5;

[0075] The valve seat 4 is radially movably arranged in the first accommodating space 51 and is located between the valve seat pressure ring 5 and the butterfly plate 2 .

[0076] The valve seat 4 itself is in the shape of a ring. When the butterfly valve is closed, the butterfly plate 2 squeezes and leans against the valve seat 4. If the butterfly plate 2 and the valve seat 4 cannot fit tightly, there mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com