Automatic fine drilling machine

A drilling machine and automatic technology, applied in the direction of boring/drilling, drilling/drilling equipment, drilling templates for workpieces, etc., can solve the problems of low efficiency, achieve the effects of reducing pollution, avoiding waste, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

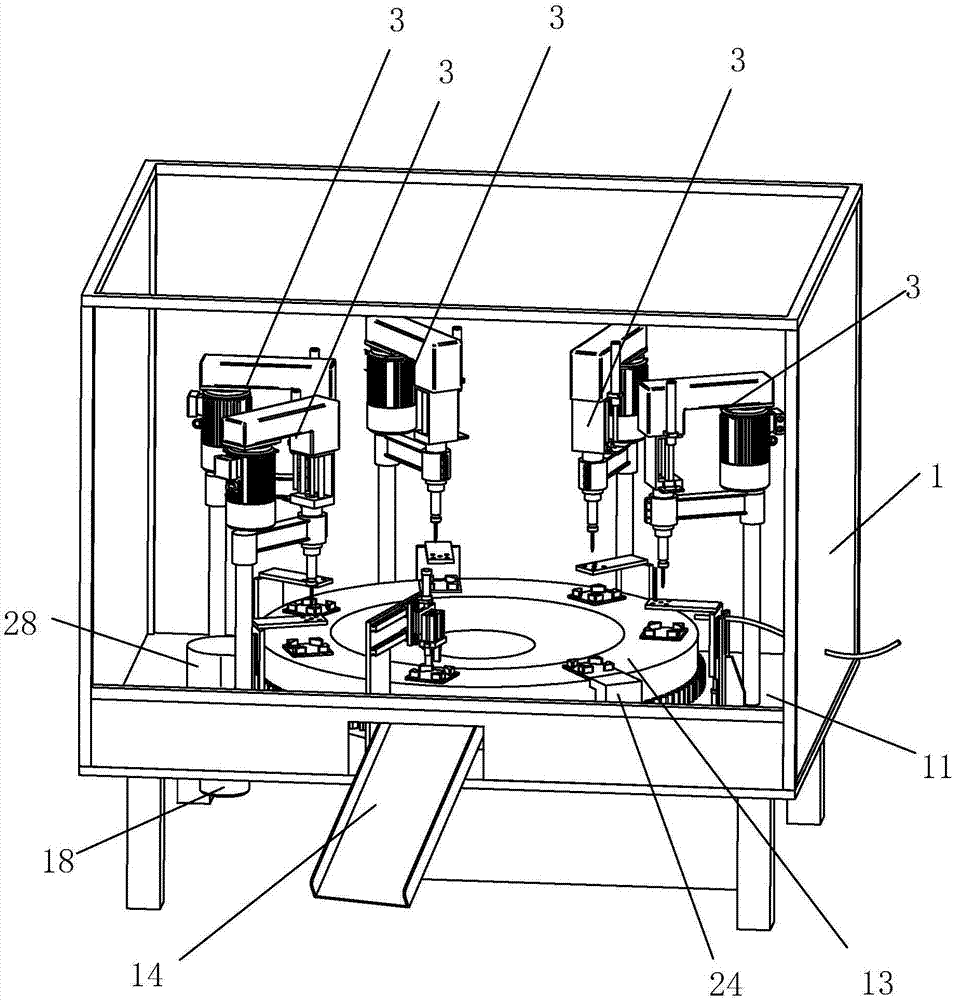

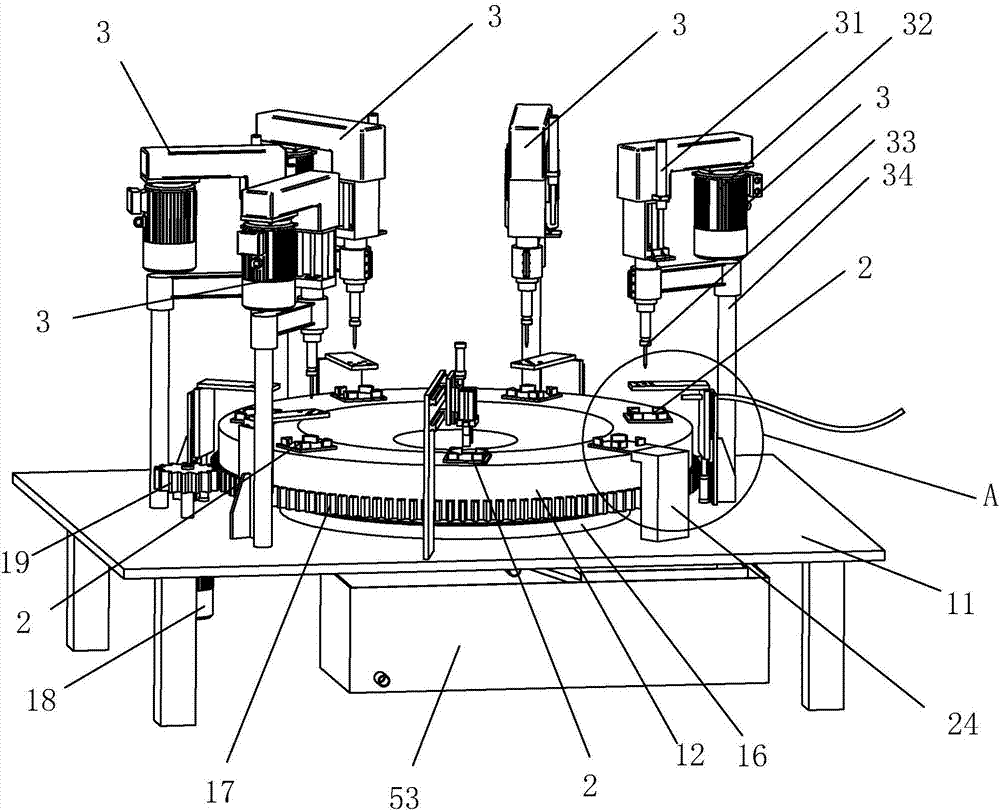

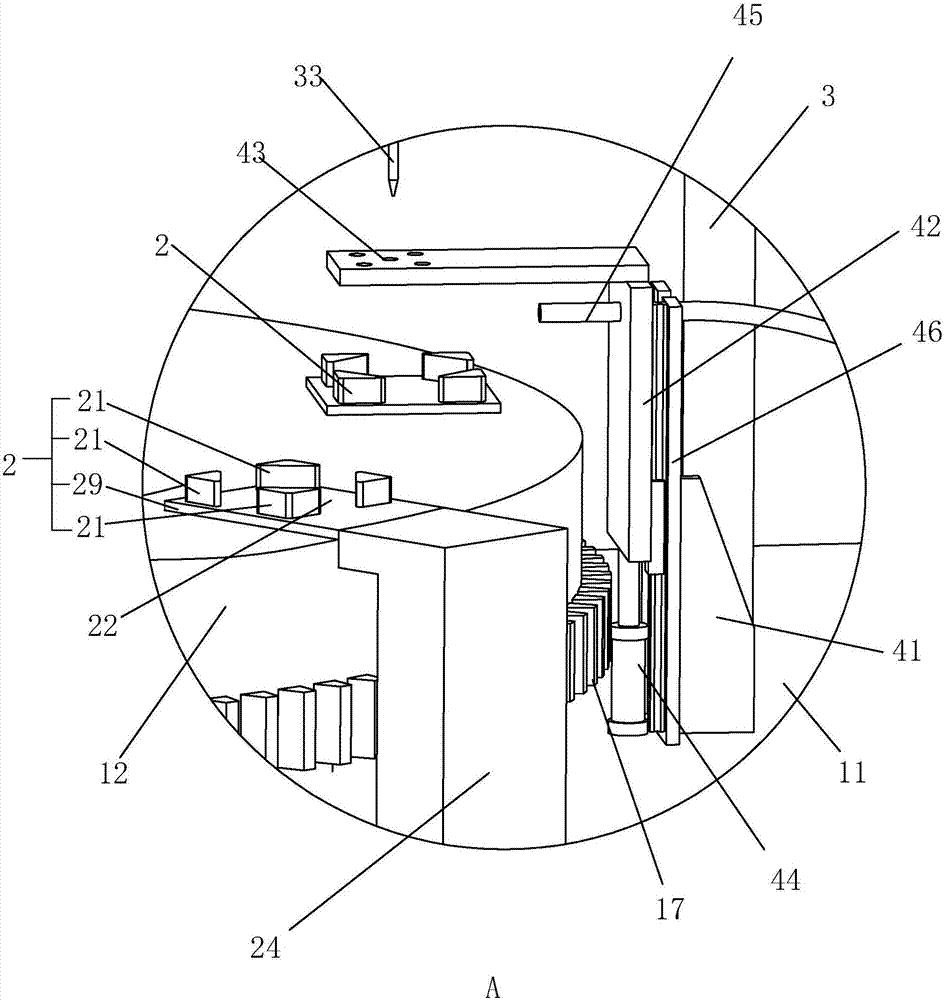

[0035] Embodiment 1: as figure 1 and figure 2 As shown, an automatic precision drilling machine includes a casing 1, and a support plate 11 is arranged inside the casing 1, and the support plate 11 extends along the horizontal direction, and supports the components of the precision drilling machine.

[0036] Such as figure 1 and figure 2 As shown, a working disc 12 is arranged on the surface of the supporting plate 11, and a needle bearing 16 is arranged between the working disc 12 and the supporting plate 11, as Figure 4 As shown, the upper surface of the needle roller bearing 16 is connected to the work disk 12, and the lower surface of the needle roller bearing 16 is connected to the support plate 11, which facilitates the rotational connection between the work disk 12 and the support plate 11, and at the same time the work disk 12 rotates in the horizontal direction of, such as image 3 and Figure 4 As shown, a ring gear 17 is provided on the circumferential side of...

Embodiment 2

[0046] Embodiment 2: An automatic precision drilling machine. The difference between Embodiment 2 and Embodiment 1 is that the cooling water and debris in the mixture are separated in Embodiment 2. In embodiment 2, such as Figure 6 As shown, the collection device 5 below the chip drop hole 15 includes not only the cooling water collection box 53 but also the chip box 55 .

[0047] Such as Figure 6 As shown, the shape of the through hole 51 is a square, the inner side wall of the through hole 51 is provided with a blanking plate 52, the blanking plate 52 is inclined, and the side wall of the blanking plate 52 is welded to the side wall of the through hole 51, The blanking plate 52 is evenly distributed with diversion holes 54. In order to simplify production, the blanking plate 52 can also be made of wire mesh. One end is located below the orthographic projection of the chip drop hole 15, and the area of the blanking plate 52 is greater than the orthographic projection ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com