Mobile mandril cooling and lubricating device

A technology of cooling, lubricating, and moving cores, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of low production efficiency, pollute the working environment, reduce the lubrication effect, etc., to improve the service life, reduce environmental pollution, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

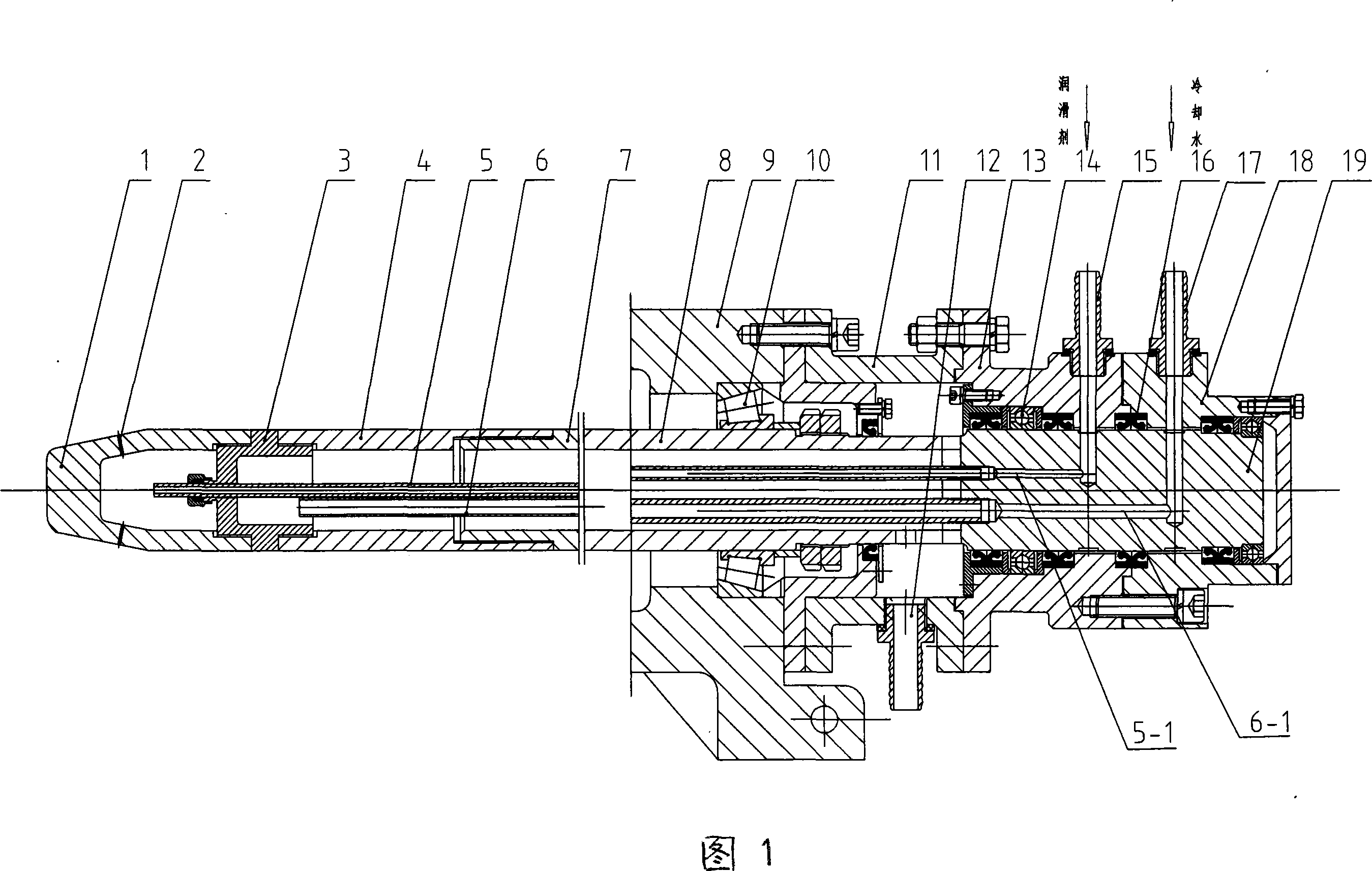

[0010] As shown in Figure 1, a cooling and lubricating device for a movable mandrel, one end of the movable hollow mandrel 4 is threadedly connected with the sealing joint 3 and the other end is threadedly connected with the hollow mandrel 7, and the hollow mandrel 7 is connected with the The hollow ejector rod small axle 8 is connected, and it is characterized in that: a bearing I 10 is arranged between the hollow ejector rod small axle 8 and the ejector rod small car body 9, and the hollow ejector rod small axle 8 is connected with the rotating shaft 19, and the rotating shaft 19 is installed in the transition flange 11, the sleeve frame 13 and the joint body 18 connected with the push rod trolley body 9 through the bearing II 14. The lubricant joint 15 is installed on the sleeve frame 13, and is connected with the lubricant channel in the rotating shaft 19 5-1 communication, the joint body 18 is equipped with a cooling water joint 17, and communicates with the cooling water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com