Multifunctional cake forming machine

A molding machine, multi-functional technology, applied in the direction of dough extruder, food molding, food science, etc., can solve the problems of complicated operation, complicated operation, poor reliability and stability of work operation, etc., and achieve simple operation and high molding efficiency High, reliable and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

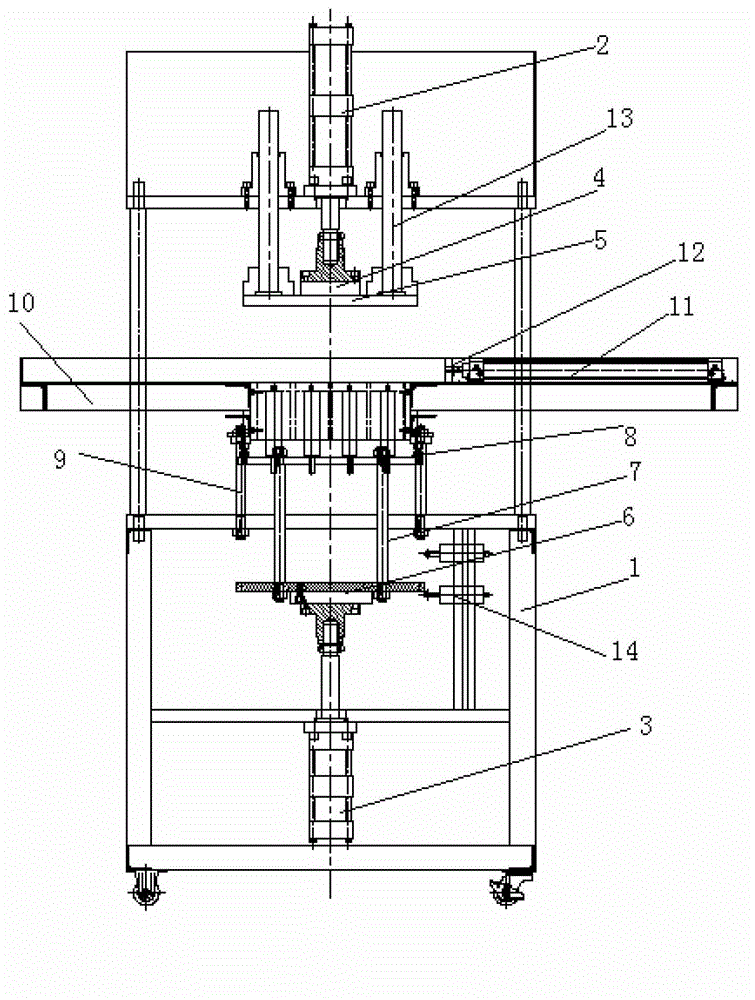

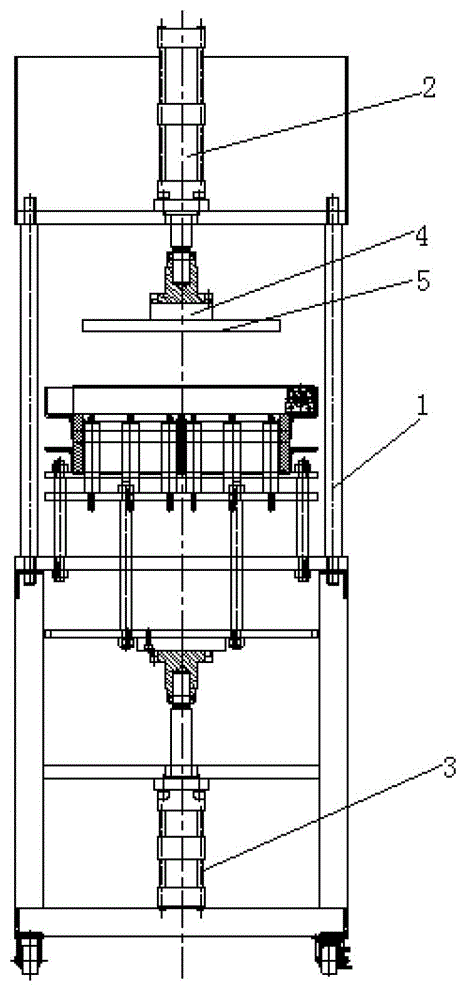

[0010] Referring to the accompanying drawings, the multifunctional pastry molding machine includes a frame 1, the top and bottom of the frame 1 are respectively fixedly equipped with an upper oil cylinder 2 and a lower oil cylinder 3, and the piston rod of the upper oil cylinder 2 is fixedly connected with an upper platen 4, An outer mold 5 is arranged below the upper pressing plate 4, a lower pressing plate 6 is fixedly connected to the piston rod of the lower oil cylinder 3, an upper ejector rod 7 is connected to the lower pressing plate 6, an inner mold 8 is arranged above the upper ejector rod 7, and the inner mold 8 passes through The fixed rod 9 below it is installed, and a feeding platform 10 is arranged between the outer mold 5 and the inner mold 8, and one end of the feeding platform 10 is fixedly provided with a pusher cylinder 11, and the piston rod of the pusher cylinder 11 is connected with a scraper 12. Guide rods 13 are respectively fixed on both sides of the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com